Rotor position detection device, positioning and operation control method of switched reluctance motor

A switched reluctance motor, rotor position detection technology, used in motor control, AC motor control, electromechanical devices and other directions, can solve the problem of inability to accurately obtain the rotor position, the motor is not in the optimal state, etc., to achieve accurate calculation, improve operation Efficiency and accurate positioning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

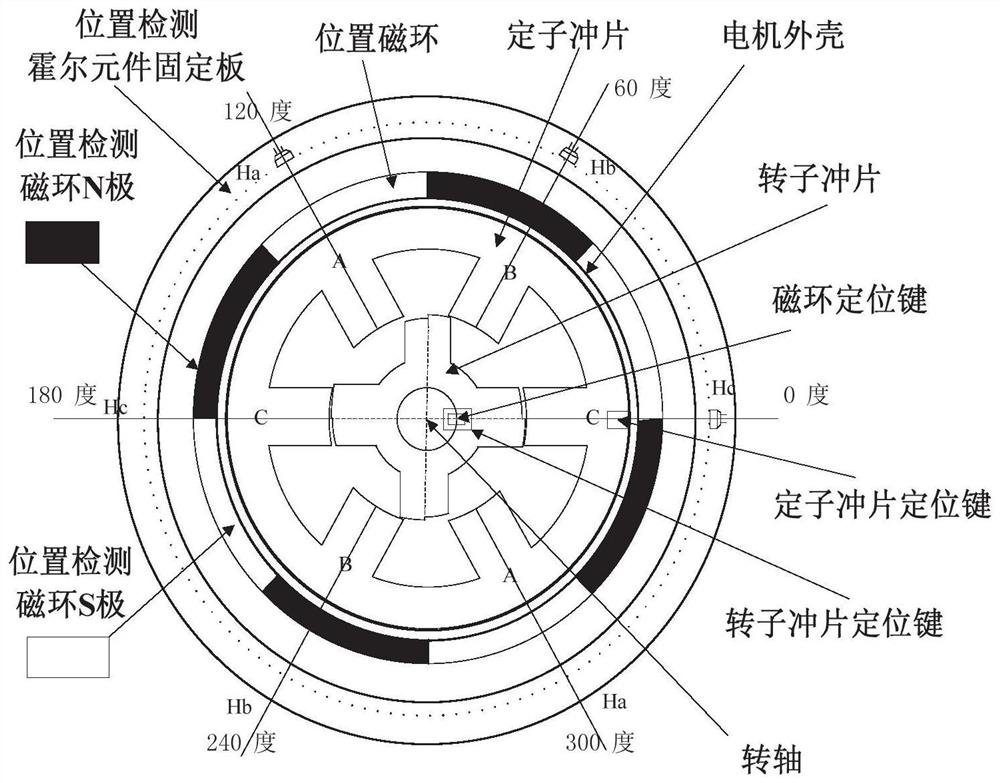

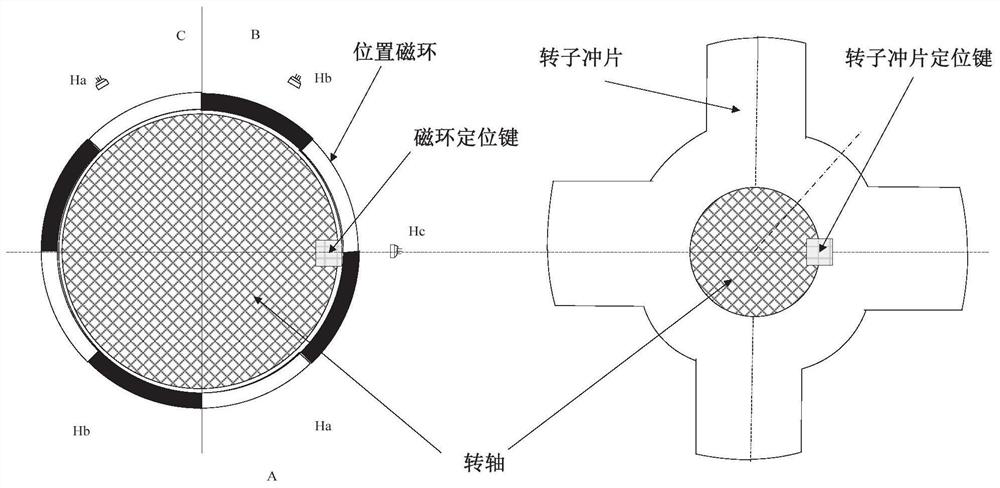

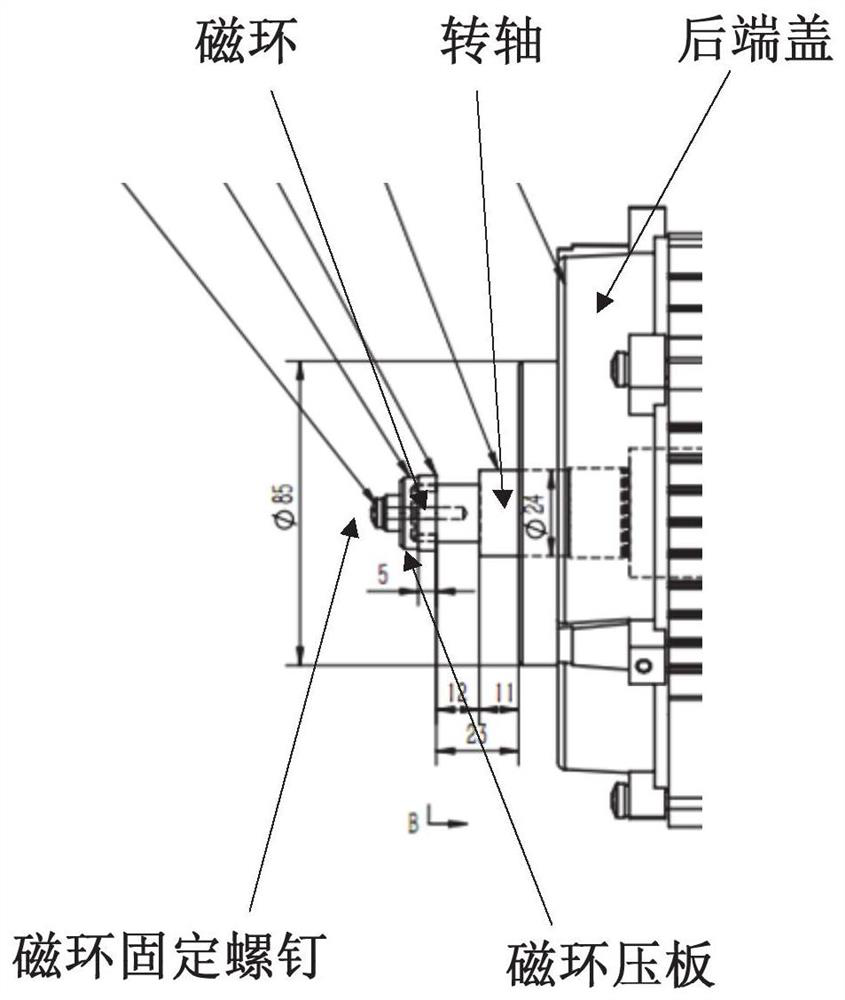

[0035] Such as figure 1 As shown, this embodiment provides a rotor position detection device for a switched reluctance motor, including: a switched reluctance motor, a magnetic ring positioning key, a rotor punching positioning key, and a stator punching positioning key;

[0036] The position magnetic ring is installed on the rotating shaft of the switched reluctance motor, and the position magnetic ring includes magnetic poles N and magnetic poles arranged alternately, and the magnetic ring positioning key is installed in the alternate position and in the horizontal direction of the axis of the rotating shaft, and the magnetic ring positioning The installation position of the key is the same as that of the positioning key of the rotor punch; the positioning key of the stator punch is installed on the axis of the stator punch of the switched reluctance motor, and a Hall element is installed at the axis of the stator punch;

[0037] The rotor rotation angle is obtained accordin...

Embodiment 2

[0052] This embodiment provides a positioning method for a rotor position detection device of a switched reluctance motor. The device uses the device described in Embodiment 1, including:

[0053] S1: Set the horizontal position of the shaft axis where the magnetic ring positioning key and the rotor punching positioning key are located to zero angle; initialize the state of the Hall element, and set the number of current state changes to zero;

[0054] S2: Obtain the pulse signal sequence of the Hall element during the rotation of the position magnetic ring, obtain the state change times of the Hall element, and obtain the first rotation angle according to the state change times of the Hall element;

[0055] S3: Obtain the motor speed according to the time of two adjacent state transitions of the Hall element;

[0056] S4: Obtain the number of motor interruptions and a single angle increment in the state change cycle according to the motor speed;

[0057] S5: Obtain the rotor...

Embodiment 3

[0097] This embodiment provides a method for controlling the turn-on and turn-off angles of the motor during operation based on the rotor position of the switched reluctance motor, including:

[0098] S1: Obtain the interrupt increment value according to the target turn-on angle or target turn-off angle and the single angle increment obtained by the method described in the second aspect;

[0099] S2: judging whether the rotor rotation angle reaches the interrupt increment value, so as to control the turn-on angle or turn-off angle of the switched reluctance motor.

[0100] Such as Figure 4 As shown, the linear inductance curve of the B-phase winding of the switched reluctance motor is used for illustration. When the state 010->011 transitions, the angle is 0 degrees; when the state 011->001 transitions, the angle is 15 degrees. At this time, the B-phase inductance is in the minimum value state ;State 001->101 transition, the angle is 30 degrees, at this time, the inductance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com