Multifunctional thickening agent and preparation method thereof

A thickening agent, multifunctional technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of formation damage, product dispersion and stability deterioration, etc., achieve rapid dissolution, fast dissolution speed, The effect of solving the instability of dispersion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

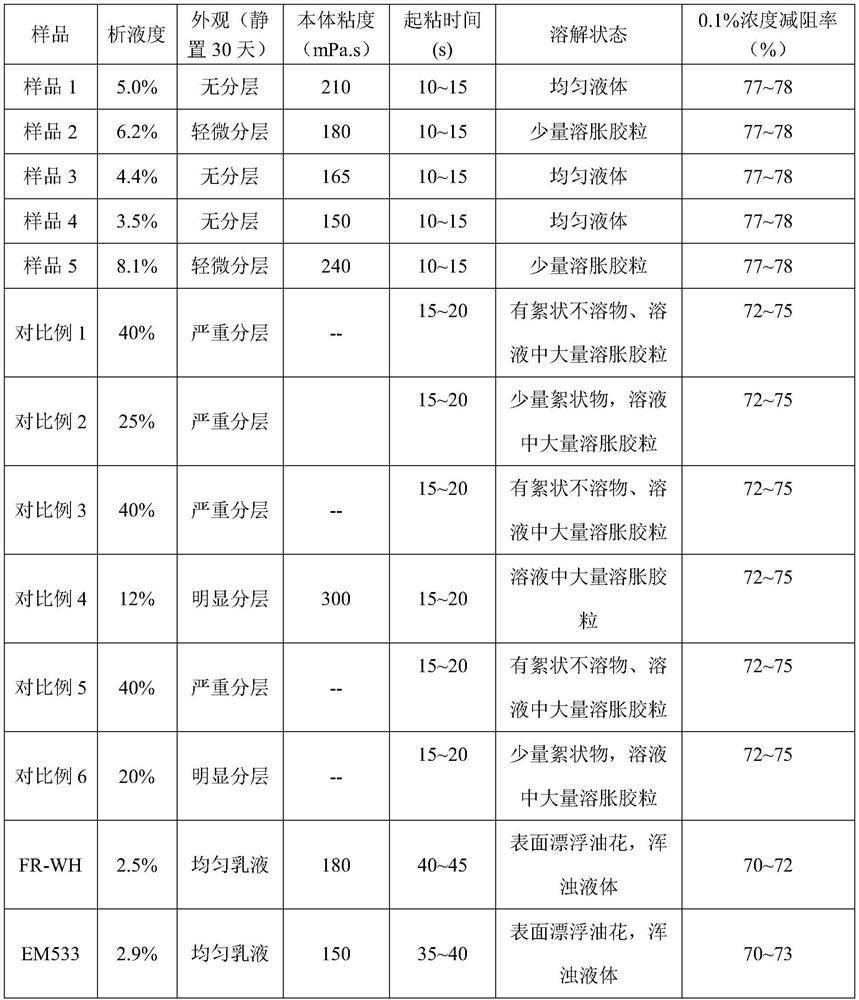

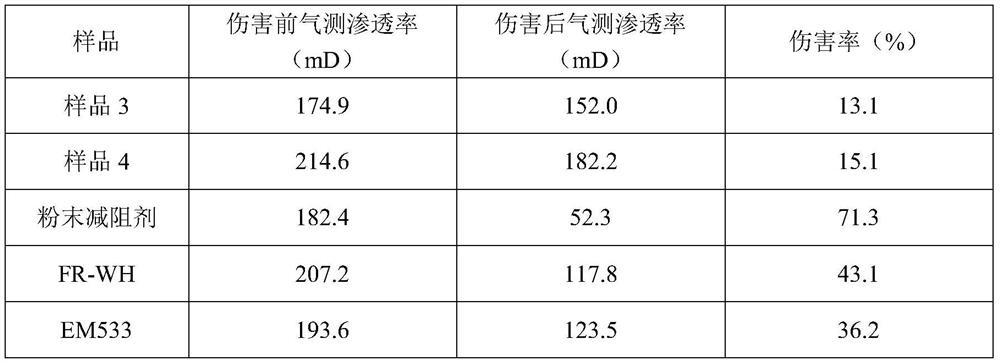

Examples

Embodiment 1

[0046] 1.1 Raw materials:

[0047] Preparation of SDS modified bentonite raw materials:

[0048] By weight, sodium carbonate: 1 part; water: 99 parts; sodium dodecylsulfonate: 2 parts; bentonite: 10 parts;

[0049] Prepare multifunctional thickener raw material of the present invention:

[0050] By weight, water-soluble thickening agent: 30 parts; Acetonide: 55 parts; D-limonene: 4 parts; Suspending agent: 1.5 parts; Water-soluble thickening agent adopts polyacrylamide, and suspending agent adopts SDS modification Bentonite.

[0051] 1.2 Preparation method:

[0052] Include the following steps:

[0053] S1: Preparation of SDS modified bentonite;

[0054] (1) Add water and sodium carbonate to the reaction vessel. After the sodium carbonate is dissolved, add sodium dodecylsulfonate and bentonite to the reaction vessel, start stirring, raise the temperature to 60°C and keep it at 60°C, frequency 40KHZ Ultrasonic vibration and dispersion for 3 hours; modified bentonite semi-...

Embodiment 2

[0061] 2.1 Raw materials:

[0062] Preparation of SDS modified bentonite raw materials:

[0063] By weight, sodium carbonate: 1 part; water: 99 parts; sodium dodecylsulfonate: 2 parts; bentonite: 10 parts;

[0064] Prepare multifunctional thickener raw material of the present invention:

[0065] By weight, water-soluble thickener: 50 parts; acetonide: 45 parts; D-limonene: 3 parts; suspending agent: 1 part, water-soluble thickening agent adopts polyacrylamide, and suspending agent adopts SDS modification Bentonite.

[0066] 2.2 Preparation method:

[0067] Include the following steps:

[0068] S1: Preparation of SDS modified bentonite;

[0069] (1) Add water and sodium carbonate to the reaction vessel. After the sodium carbonate is dissolved, add sodium dodecylsulfonate and bentonite to the reaction vessel, start stirring, raise the temperature to 65°C and keep it at 65°C, frequency 45KHZ Ultrasonic vibration and dispersion for 2.5 hours; modified bentonite semi-finished...

Embodiment 3

[0076] 3.1 Raw materials:

[0077] Preparation of SDS modified bentonite raw materials:

[0078] By weight, sodium carbonate: 1 part; water: 99 parts; sodium dodecylsulfonate: 2 parts; bentonite: 10 parts;

[0079] Prepare multifunctional thickener raw material of the present invention:

[0080] By weight, water-soluble thickening agent: 43 parts; Acetonide: 50 parts; D-limonene: 5 parts; Suspending agent: 2 parts; Water-soluble thickening agent adopts polyacrylamide, and suspending agent adopts SDS modification Bentonite.

[0081] 3.2 Preparation method:

[0082] Include the following steps:

[0083] S1: Preparation of SDS modified bentonite;

[0084] (1) Add water and sodium carbonate to the reaction vessel. After the sodium carbonate is dissolved, add sodium dodecylsulfonate and bentonite to the reaction vessel, start stirring, raise the temperature to 55°C and keep it at 55°C, frequency 35KHZ Ultrasonic vibration and dispersion for 3.5 hours; modified bentonite semi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com