Coal and sludge mixed gasification method and device

A technology of sludge and sludge carbon, which is applied in the field of environmental engineering, can solve the problems of poor utilization stability and low blending ratio, and achieve the effect of increasing the blending rate and realizing the reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

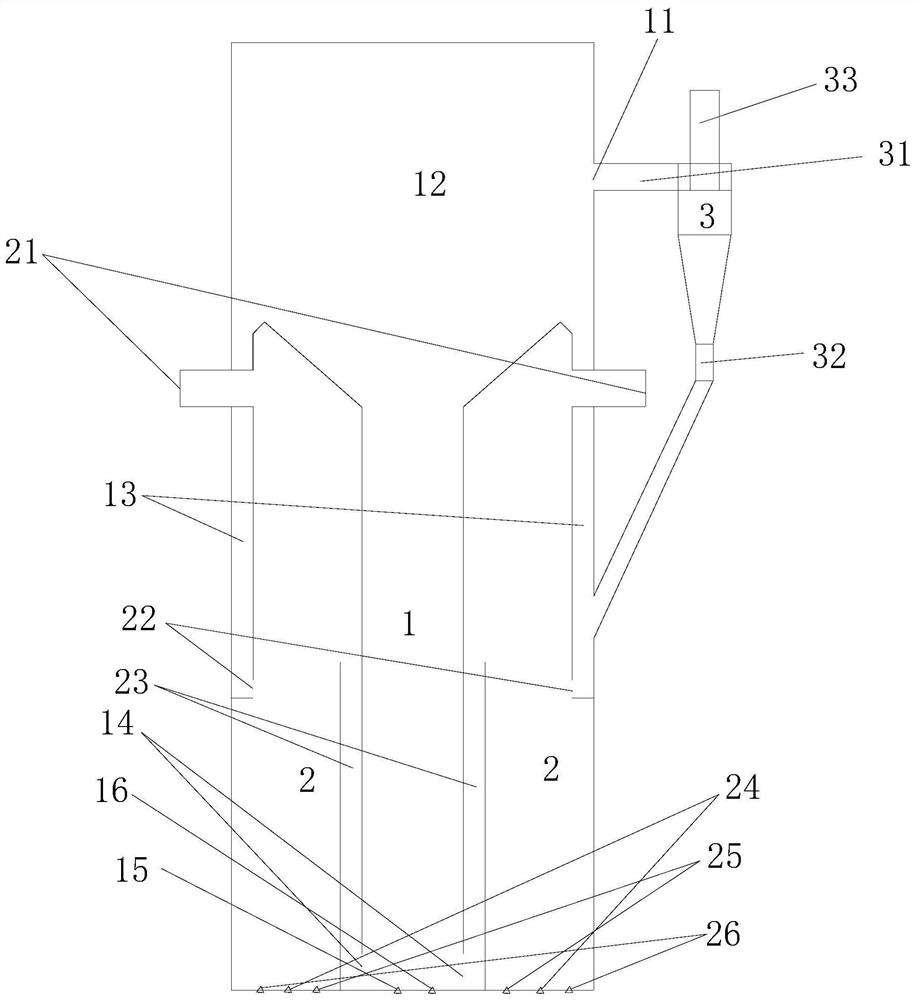

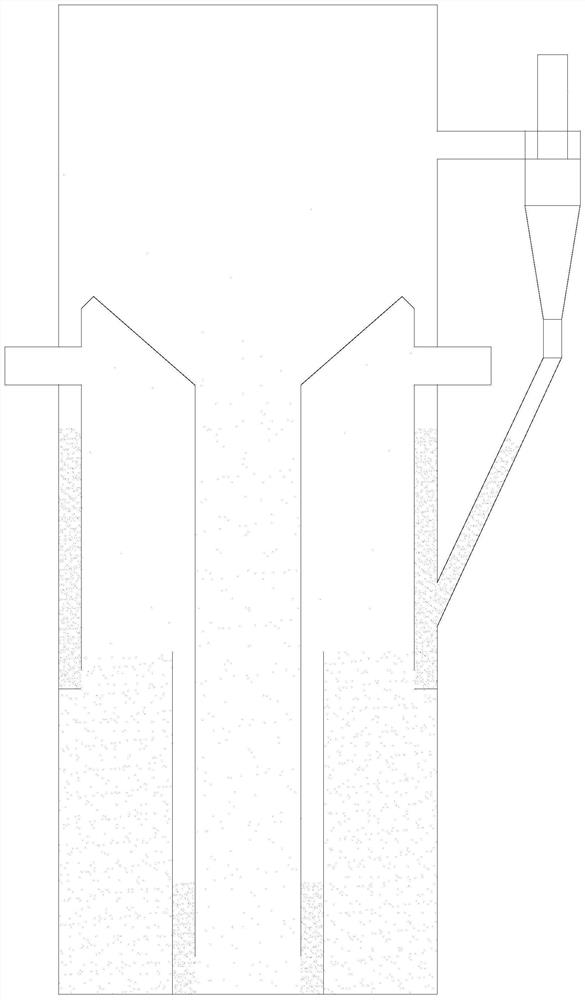

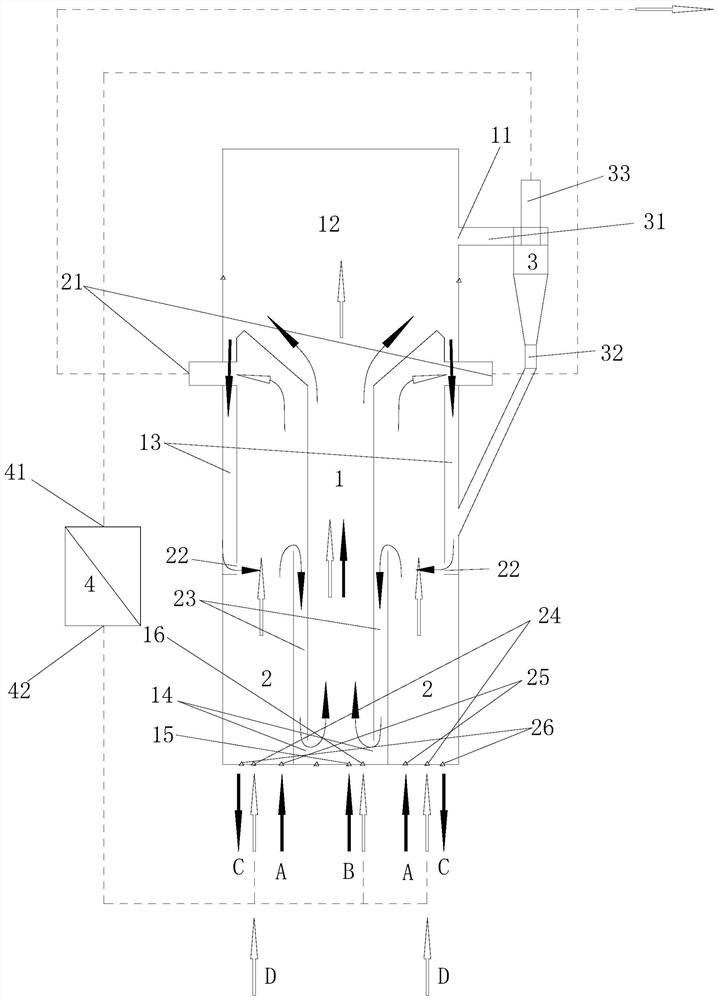

[0024] refer to Figure 1 to Figure 3 , is a method and device for mixed gasification of coal and sludge, the method comprising the following steps:

[0025] (1) Sludge devolatilization: Dried sludge with a moisture content of 35%, the sludge after simple crushing treatment forms a relatively uniform powder, and the crushed sludge enters the ascending bed 1 from the bottom of the ascending bed 1, and in the ascending bed 1 is mixed with the high-temperature bed material circulated from the lower bed 2, and the sludge is volatilized under the heating of the high-temperature bed material; 12 Automatic separation, the mixture of separated sludge carbon and bed material enters the descending bed 2;

[0026] (2) Gas-solid separation: the volatile matter produced by the sludge is separated from the gas-solid by the gas-solid separation device 3, and the solid product collected by separation is recycled to the down-bed 2;

[0027] (3) Gas-water separation of volatile matter: the vo...

Embodiment 2

[0040] Referring to Example 1, the difference between Example 2 and Example 1 is that the addition ratio of sludge to coal in the co-gasification process is 20:80. The sludge devolatilization temperature in the ascending bed 1 is set at 400°C. When the sludge enters the ascending bed 1, it reaches the temperature in the furnace within 1-2 seconds, and the heating rate is about 300°C / s. The co-gasification temperature of sludge carbon and coal was set at 1300°C. The gasification equivalent ratio consumed by gasification in step (4) is set at 0.35. The gasification agent supplied is air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com