Flame-retardant high-temperature-resistant cable

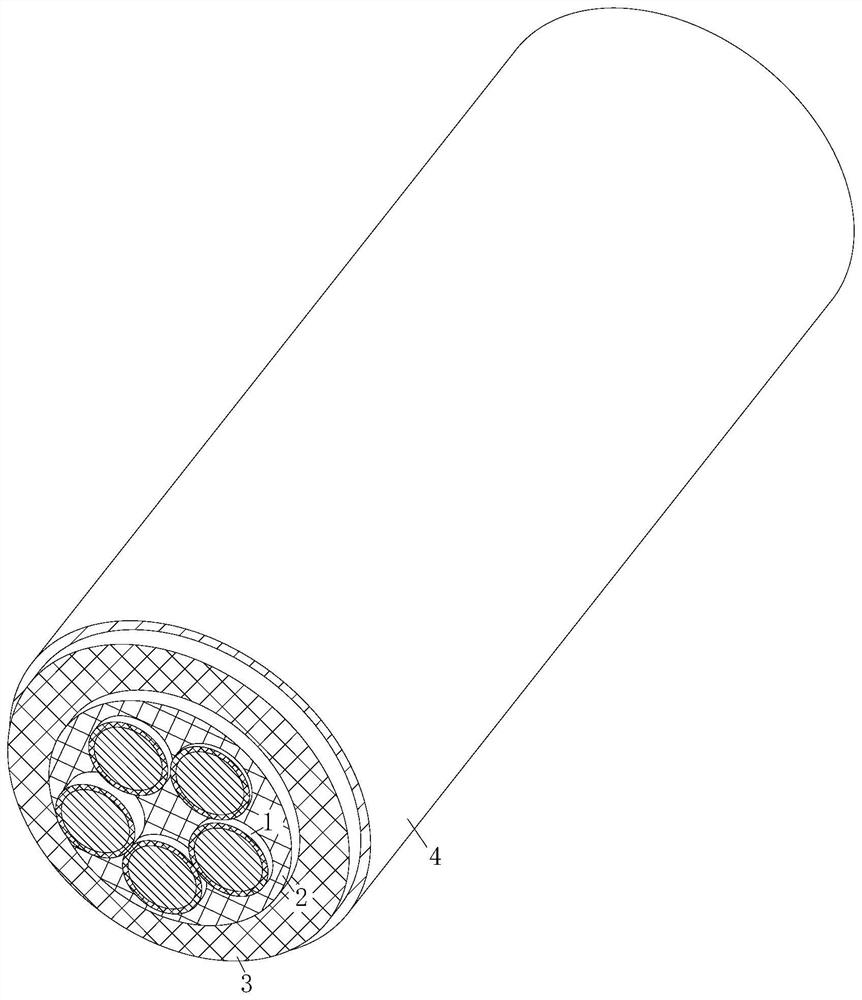

A high temperature resistant, cable technology, applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of heat can not be discharged, the internal resistance of the cable increases, people's loss, etc., to improve the actual application effect, improve the heat dissipation effect, improve the use of The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

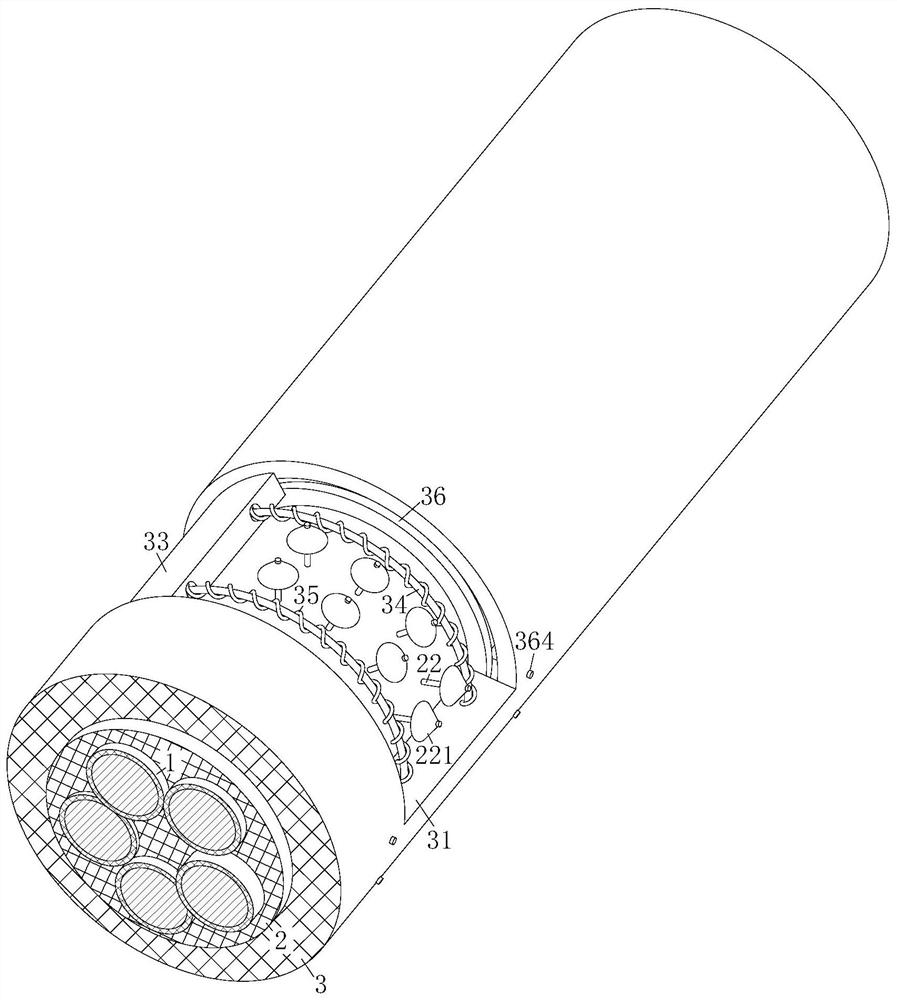

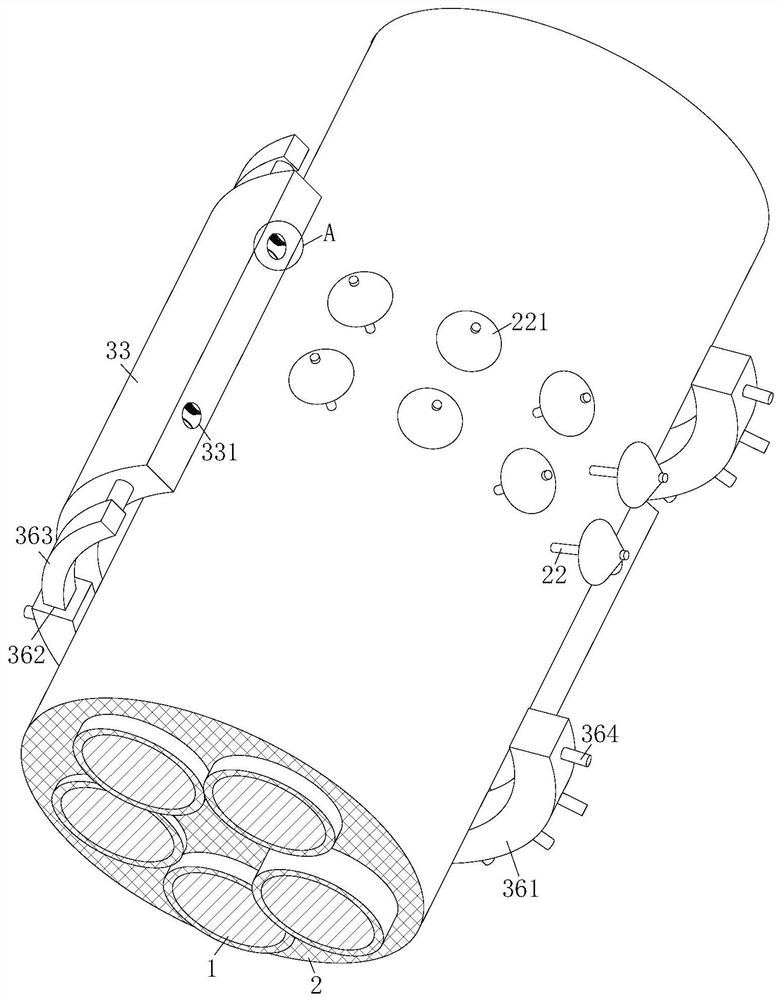

[0029] As an embodiment of the present invention, the end of the slide rod 22 is fixedly connected with a slanted piece 221; The diameter increases as it moves away from the armor layer 4; during operation, if the axis of the slide bar 22 is parallel to one end face of the arc-shaped plate 33, the arc-shaped plate 33 cannot squeeze the slide bar 22 into the air hole 21, resulting in The stuck phenomenon of the arc-shaped plate 33 makes the arc-shaped groove 31 unable to be closed in the event of a fire; therefore, in the present invention, the end of the slide bar 22 is fixedly connected with a slant piece 221, so the arc-shaped plate 33 will first face the slant piece 221. Extruding, because the end surface of the slant piece 221 has an included angle with one end surface of the arc-shaped plate 33, the slant piece 221 will drive the slide bar 22 to slide along the air hole 21 after being squeezed, so that the slide bar 22 slides into the air hole 21 Because the slant 221 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com