Wearable intraocular pressure monitoring sensor and preparation method thereof

A monitoring sensor and sensor technology, applied in the field of medical devices, can solve problems such as differences, inability to obtain intraocular pressure data, and inability to measure intraocular pressure in glaucoma patients, and achieve the effect of improving sensitivity and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

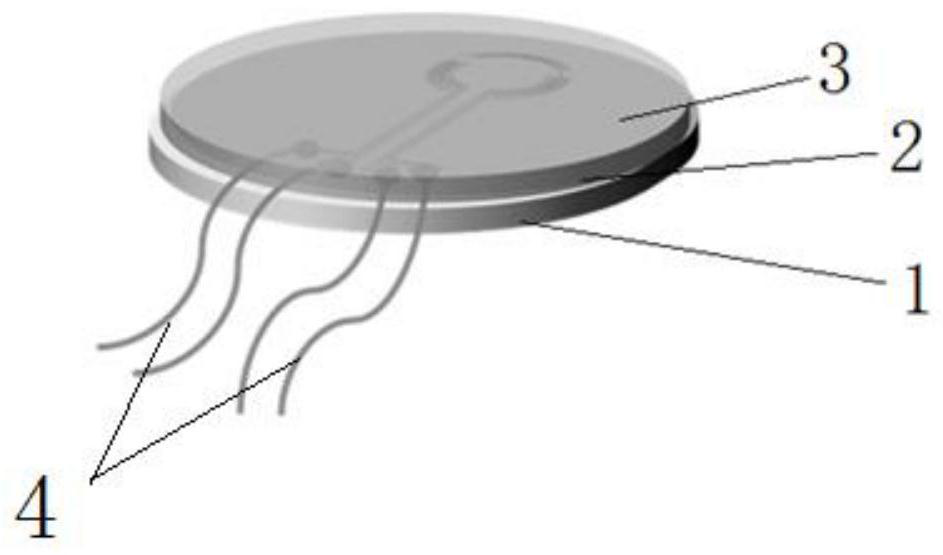

[0035] A preparation method of an intraocular pressure monitoring sensor, comprising:

[0036] (1) using polydimethylsiloxane (PDMS) as the base layer;

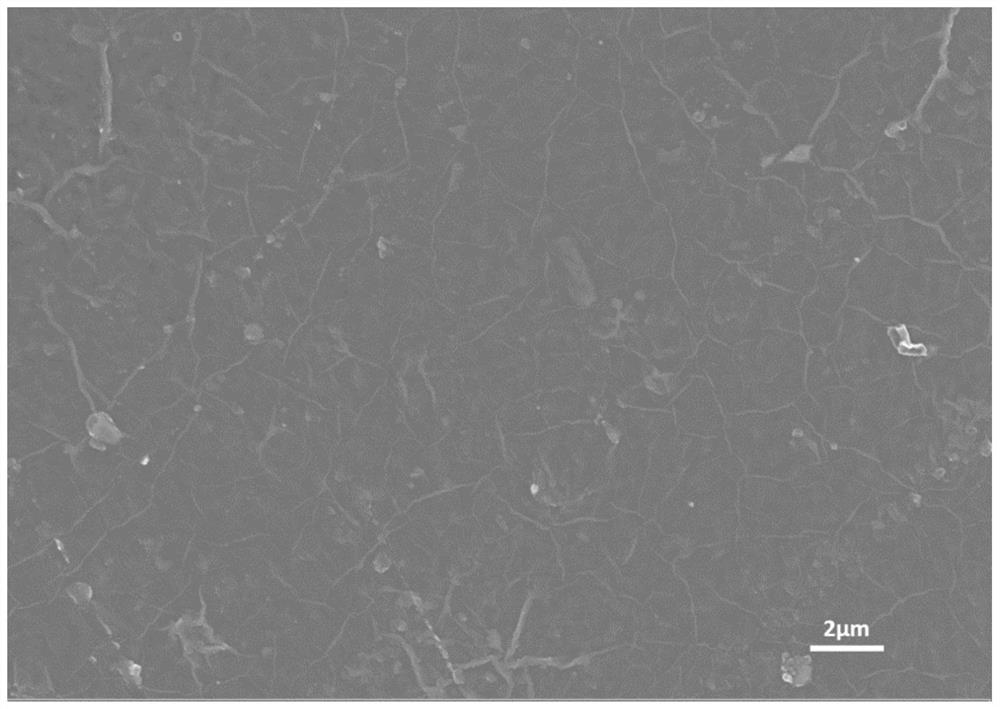

[0037] (2) Mix the reduced graphene oxide solution and the carbon nanotube solution in a volume ratio of 1:1-5:1, put it into the ultrasonic atomization spraying equipment, and spray it onto the mask plate with the designed Wheatstone bridge circuit. A film is formed on the base layer, and the film obtained by spraying is thermally reduced, which is the strain sensing layer; the concentration of the reduced graphene oxide solution is 0.5mg-2mg / mL, and the concentration of the carbon nanotube solution is 0.2-0.5mg / mL; The total spraying time is 3-6 hours; the process conditions of thermal reduction: under the condition of 180 ℃-200 ℃, the reduction is 2-3 hours;

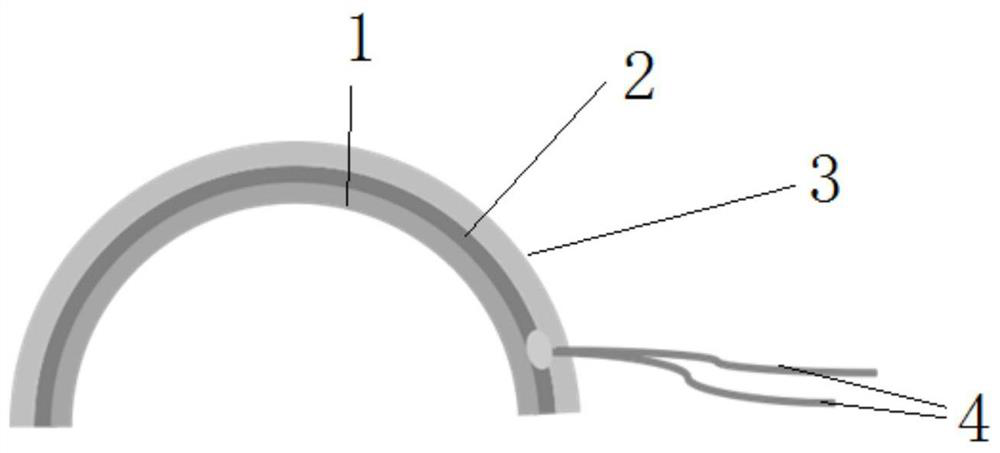

[0038] (3) Coating Parylene on the strain sensing layer to form an encapsulation layer, and then forming a certain curvature radius of 8-10 mm by thermoplastic to o...

Embodiment 1

[0043] (1) using polydimethylsiloxane (PDMS) as the base layer;

[0044] (2) Mix the reduced graphene oxide solution and the carbon nanotube solution in a volume ratio of 1:1, put it into an ultrasonic atomization spraying equipment, and spray it onto the base layer through a mask with a designed Wheatstone bridge circuit to form Thin film, thermal reduction of the film obtained by spraying is the strain sensing layer; wherein, the concentration of the reduced graphene oxide solution is 0.5 mg / mL, and the concentration of the carbon nanotube solution is 0.2 mg / mL; the total spraying time is 3 hours ; Process conditions for thermal reduction: at 180°C, reduction for 2 hours; the thickness of the formed strain-sensing layer is 100 μm;

[0045](3) Coat the top of the strain-sensing layer with Parylene to form an encapsulation layer, and then use three metal spherical molds (12mm, 10mm and 8mm) with gradually decreasing curvature radii for shaping. First, put the obtained sensor ...

Embodiment 2

[0047] (1) using polydimethylsiloxane (PDMS) as the base layer;

[0048] (2) Mix the reduced graphene oxide solution and the carbon nanotube solution in a volume ratio of 5:1, put it into the ultrasonic atomization spraying equipment, and spray it onto the base layer through the mask that has designed the Wheatstone bridge circuit to form Film, the film obtained by spraying is thermally reduced, which is the strain sensing layer; wherein, the concentration of the reduced graphene oxide solution is 2 mg / mL, and the concentration of the carbon nanotube solution is 0.5 mg / mL; the total spraying time is 6 hours; Process conditions for thermal reduction: reduction at 200°C for 3 hours; the thickness of the formed strain-sensing layer is 200 μm;

[0049] (3) Coat the top of the strain-sensing layer with Parylene to form an encapsulation layer, and then use three metal spherical molds (14mm, 12mm and 10mm) with gradually decreasing radii for shaping. First, put the obtained sensor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com