Cutting equipment and control method thereof

A technology of cutting equipment and cutting machine, applied in metal processing equipment, measuring/indicating equipment, manufacturing tools, etc., can solve the problems of inability to realize circular cutting and sorting of steel plates, low cutting efficiency, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

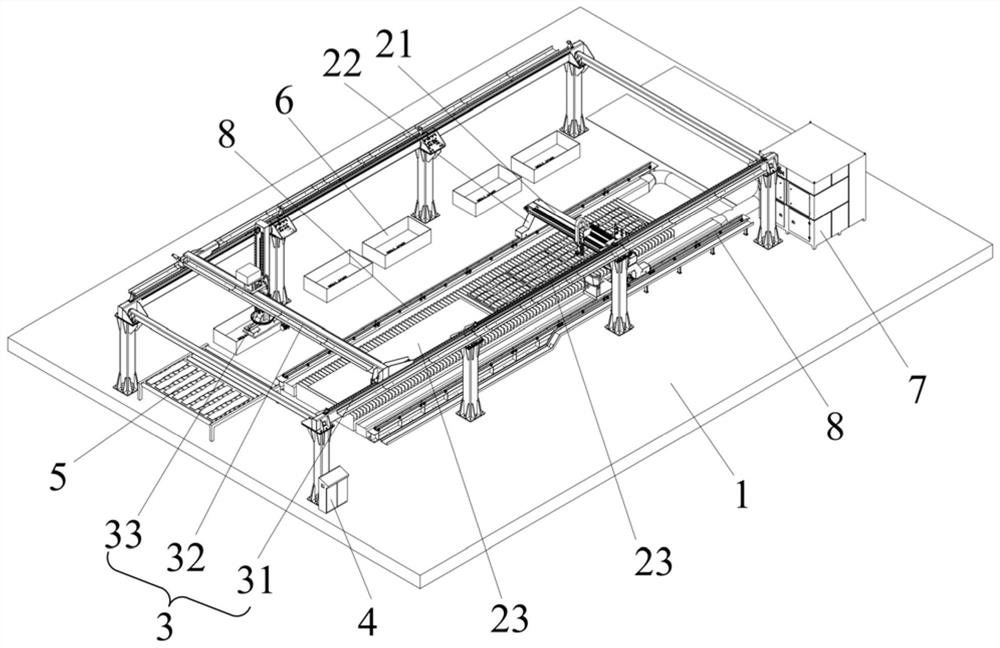

[0044] In this embodiment, a cutting device is proposed. The cutting device is arranged on the bottom plate 1. The cutting device can realize the circular cutting and sorting work of the pieces to be cut, so that the working efficiency of cutting and sorting is high, and the entire cutting device High degree of automation. Specifically, such as figure 1As shown, the cutting equipment includes a cutting system, a truss system 3 and a control system 4 . The cutting system is arranged inside the truss system 3 , and the control system 4 is arranged outside the truss system 3 . Wherein, the cutting system includes a cutting machine 21 and two cutting stations 23 arranged side by side. The cutting machine 21 is slidably arranged on the top of the cutting station 23. The cutting machine 21 can slide relative to the cutting station 23. Positions 23 are provided with sensors for detecting the position of the piece to be cut; the truss system 3 includes a bracket 31 and an adsorption...

Embodiment 2

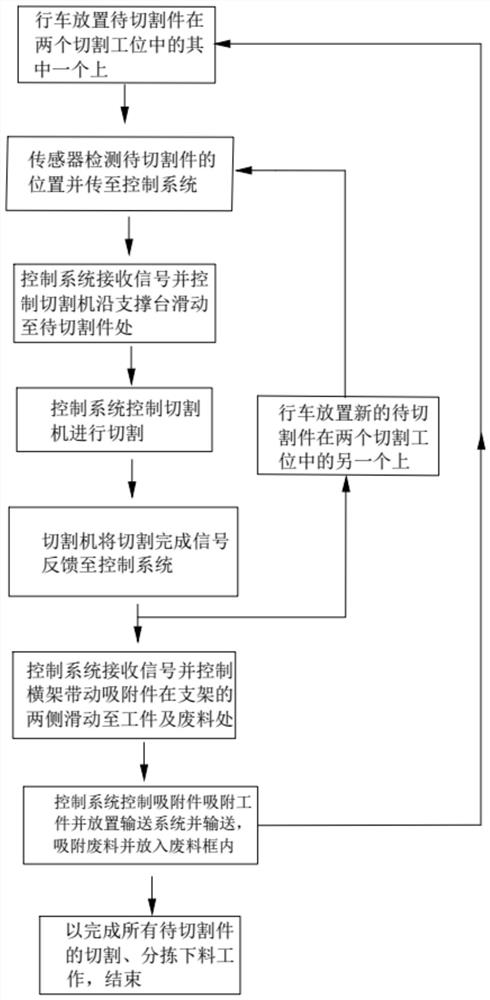

[0059] In this embodiment, a control method based on the cutting device in the first embodiment is proposed, and the control method of the cutting device includes the following steps:

[0060] Place the piece to be cut: place the piece to be cut on one of the two cutting stations 23, the sensor detects the position of the piece to be cut and transmits it to the control system 4;

[0061] Cut the piece to be cut; the control system 4 receives the signal from the sensor, and controls the cutting machine 21 to move to the top of the piece to be cut, and the control system 4 controls the cutting machine 21 to start cutting the piece to be cut to form workpieces and waste materials. Place the piece to be cut on another of the two cutting stations 23 of the piece to be cut;

[0062]Sorting workpieces and waste materials; after the cutting machine 21 completes the cutting, it feeds back the cutting completion signal to the control system 4, and after receiving the signal, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com