Rear-end material falling device of plasma cutting machine

A technology of plasma cutting machine and blanking device, which is applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low efficiency and increased labor intensity of workers, and achieve improved cleaning efficiency, improved drying efficiency and effect, good for drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

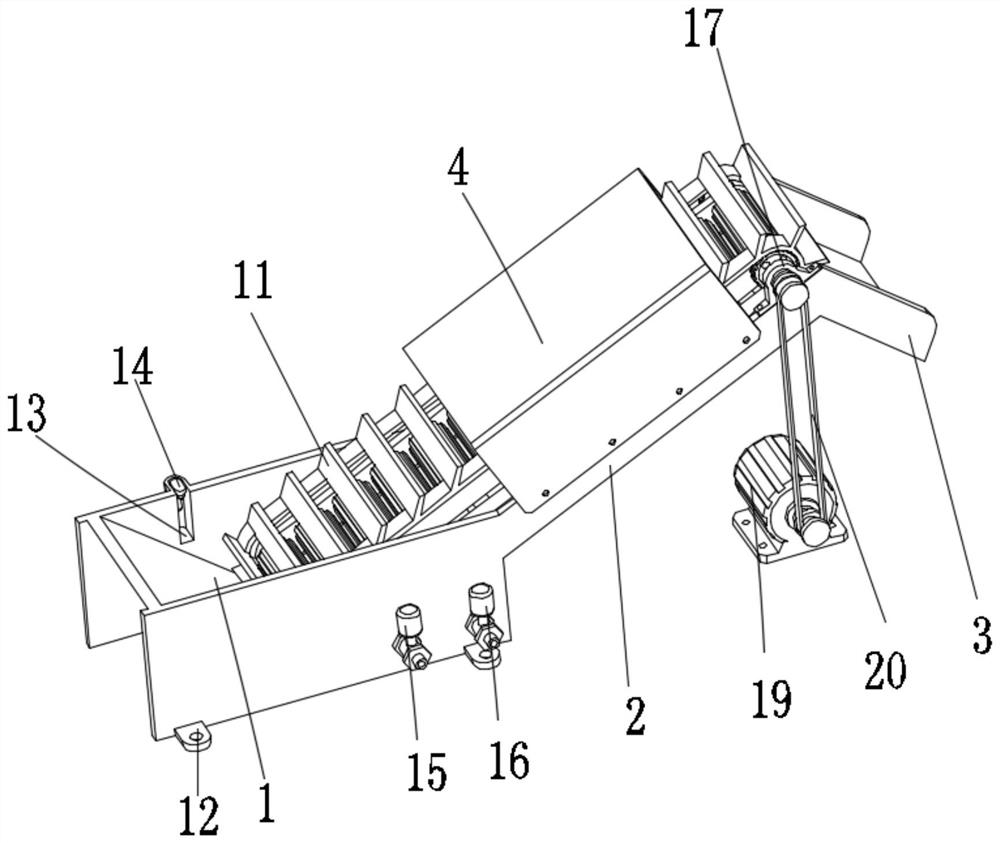

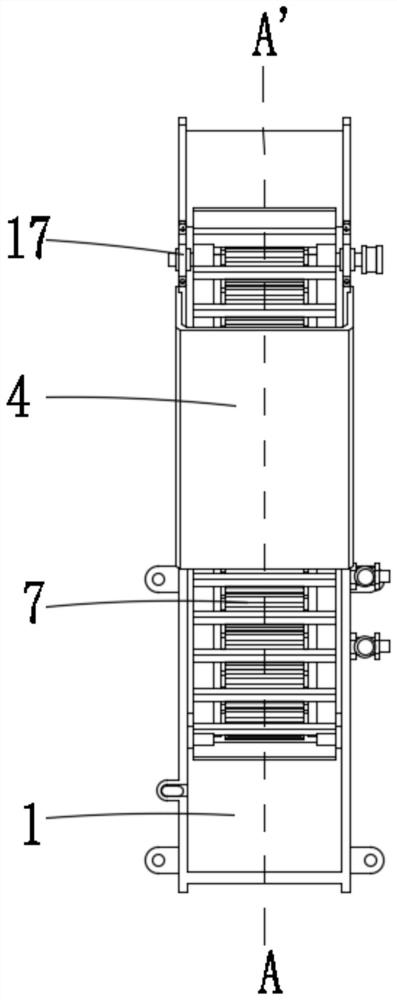

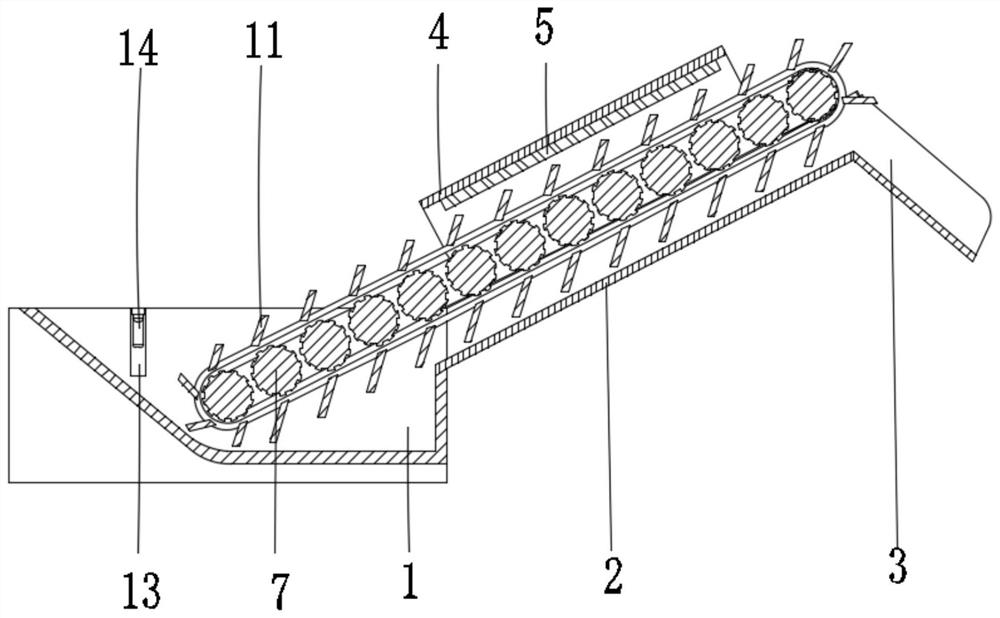

[0029] A rear-end blanking device of a plasma cutting machine in this embodiment, refer to Figure 1-5 : Including the blanking pool 1, the trapezoidal tank body is arranged in the blanking pool 1, and the right part of the material pool 1 is inclined upward to be provided with a water removal tank 2, and the right part of the water removal tank 2 is inclined downward to be provided with a discharge tank 3, and the water removal tank 2 The upper side of the middle part is provided with a resistance heating pipe 5 through the heat shield 4, and a conveying mechanism is arranged in the water removal tank 2, and the conveying mechanism includes two groups of forward and backward symmetrical conveying frames 6, several groups of rotatably connected between the two groups of conveying frames 6 The rollers 7, the gears 9 connected to the two ends of the two groups of conveying frames 6 and facing away from the side through the shaft rods 8, and the caterpillars 10 arranged between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com