Prefabricated ribbed concrete laminated slab and preparation method thereof

A laminated board and concrete technology, applied in the direction of manufacturing tools, building components, building materials, etc., can solve the problems of low factory production efficiency, difficult construction, thick floor thickness, etc., to increase the reuse rate, reduce construction difficulty, The effect of reducing structural loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing a prefabricated ribbed concrete composite slab, the steps comprising:

[0034] S1. Small concrete blocks are poured in advance;

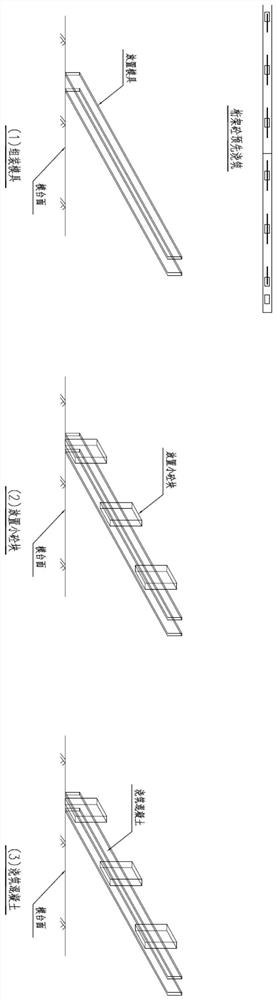

[0035] S2. Pre-pouring of truss concrete: if figure 1 As shown, a truss concrete mold is placed on the formwork surface; a certain number of poured small concrete blocks are placed on the truss concrete mold, and every two small concrete blocks are separated by a certain distance; poured in the truss concrete mold concrete;

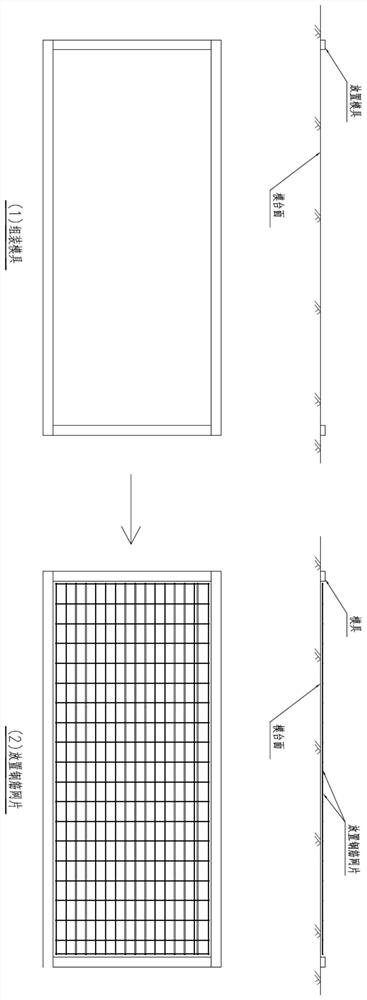

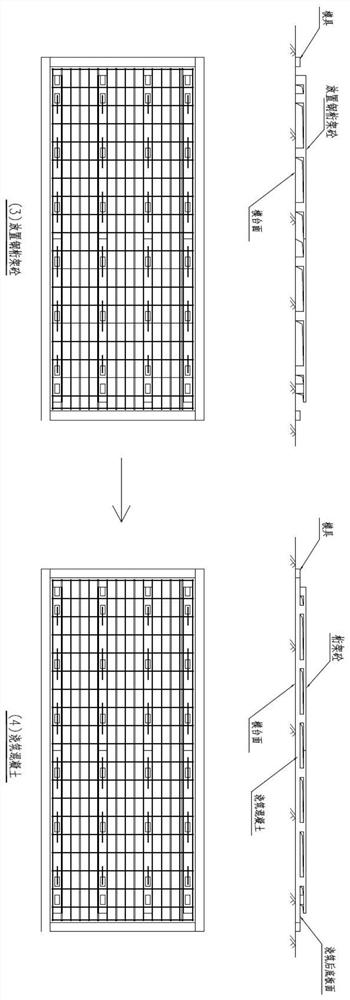

[0036] S3. Pouring forming of laminated slabs: such as figure 2 with image 3 As shown, the laminated slab mold is placed on the other mold table and assembled; the steel mesh sheet is placed in the laminated slab mold; a certain number of suspension rings are bound on the steel mesh sheet, and the pouring completed steel truss concrete; concrete is poured into the composite slab mold to obtain the prefabricated ribbed concrete composite slab.

[0037] During the prod...

Embodiment 2

[0040] Such as Figure 4 As shown, this embodiment provides a prefabricated ribbed concrete composite slab, comprising: a base plate 1, a plurality of upper chord ribs 2 perpendicular to the base plate 1 and a plurality of suspension rings 4 fixed on the upper surface of the base plate 1; The upper chord rib 2 includes a plurality of web ribs 3 arranged between the bottom plate 1 and the upper chord rib 2 , and a plurality of rectangular holes are formed between the plurality of web ribs 3 .

[0041] Preferably, during the production and construction of the bottom plate 1, steel mesh is used to cast members instead of manual binding; and there is no reinforcement on all sides. If reinforcement is required, an additional level of steel is added, and the mold does not need to be opened during production. .

[0042] Preferably, the number of the upper chord ribs 2 is four.

[0043] Preferably, the number of web ribs 3 disposed between the bottom plate 1 and a single upper chord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com