Modular vertical flow constructed wetland sewage plant tail water treatment device and method thereof

A technology of constructed wetlands and treatment devices, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as easy blockage of fillers, insufficient oxygen supply, low denitrification efficiency, etc., to achieve Reduce difficulty and cost, increase dissolved oxygen concentration, and facilitate the removal of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

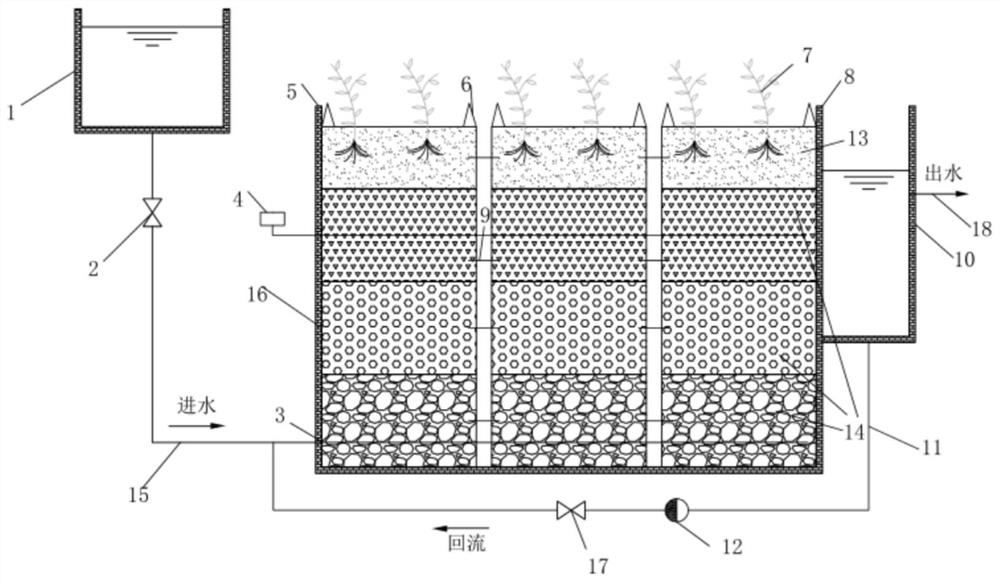

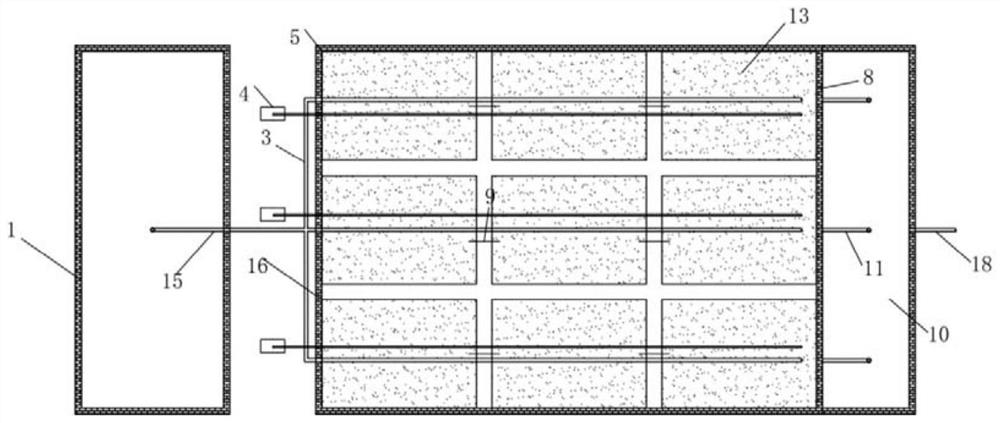

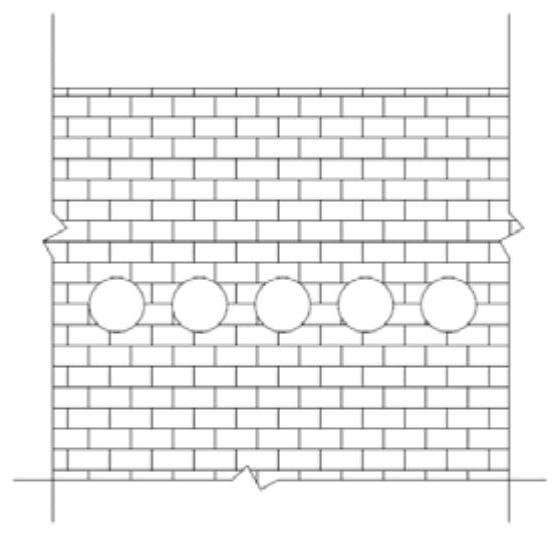

[0043]This embodiment provides a modular vertical flow artificial wetland sewage plant tail water treatment device, the structure is as follows Figure 1-3 As shown, it includes a wetland pool body 16, a plant matrix module 13, a matrix module 14, an aeration device 4, a water inlet tank 1, a water inlet pipe 15, a water distribution pipe 3, a water storage tank 10, and an outlet water return device 11. The inside of the wetland pool body 16 The pool body matrix filler is provided, and the pool body filler includes several layers of matrix module groups and a layer of plant matrix module groups stacked in sequence from bottom to top, each layer of matrix module groups and a layer of plant matrix module groups arranged on the matrix module group Each is a cuboid structure, the plant module group is composed of several plant matrix modules 13 connected horizontally through the lock 9, and each layer of matrix module group is composed of several matrix modules 14 connected horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com