Sargassum fusiforme polysaccharide and extraction method thereof

A hijiki polysaccharide and extraction method technology, applied in the field of hijiki polysaccharides and its extraction, can solve the problems of high equipment requirements, long time consumption, polysaccharide activity destruction, etc., and achieve low equipment requirements, low energy consumption, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the implementation and protection of the present invention are not limited thereto. It should be pointed out that, if there are any processes in the following that are not specifically described in detail, those skilled in the art can realize or understand with reference to the prior art. The reagents or instruments used were not indicated by the manufacturer, and they were regarded as conventional products that can be purchased from the market.

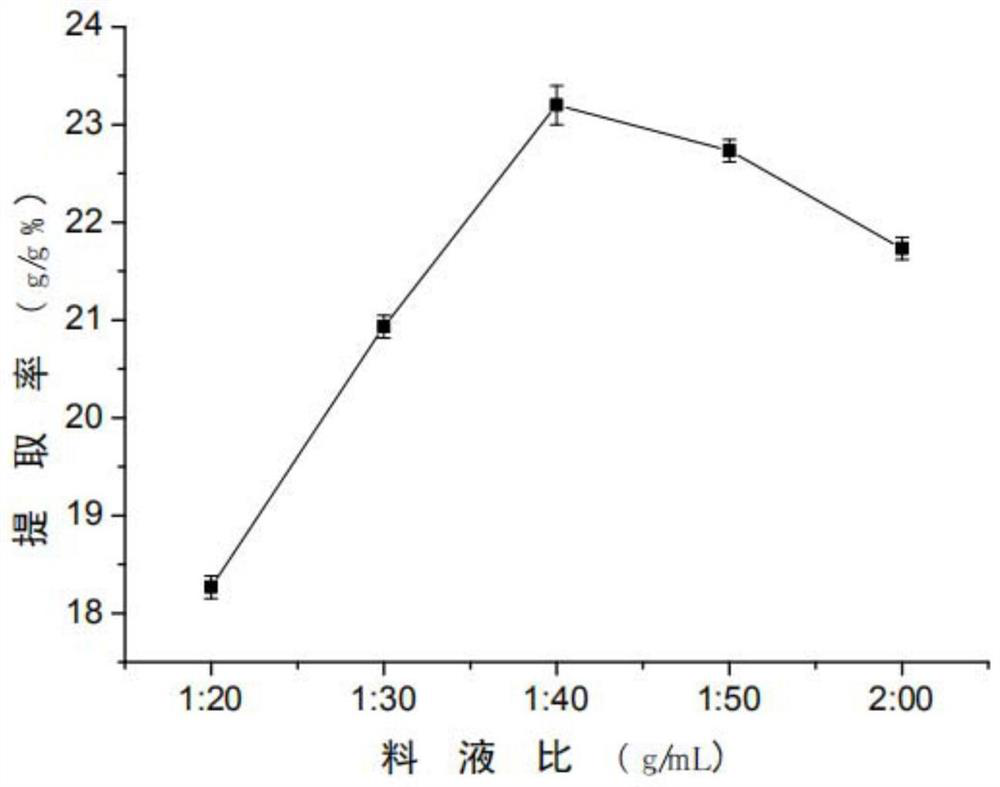

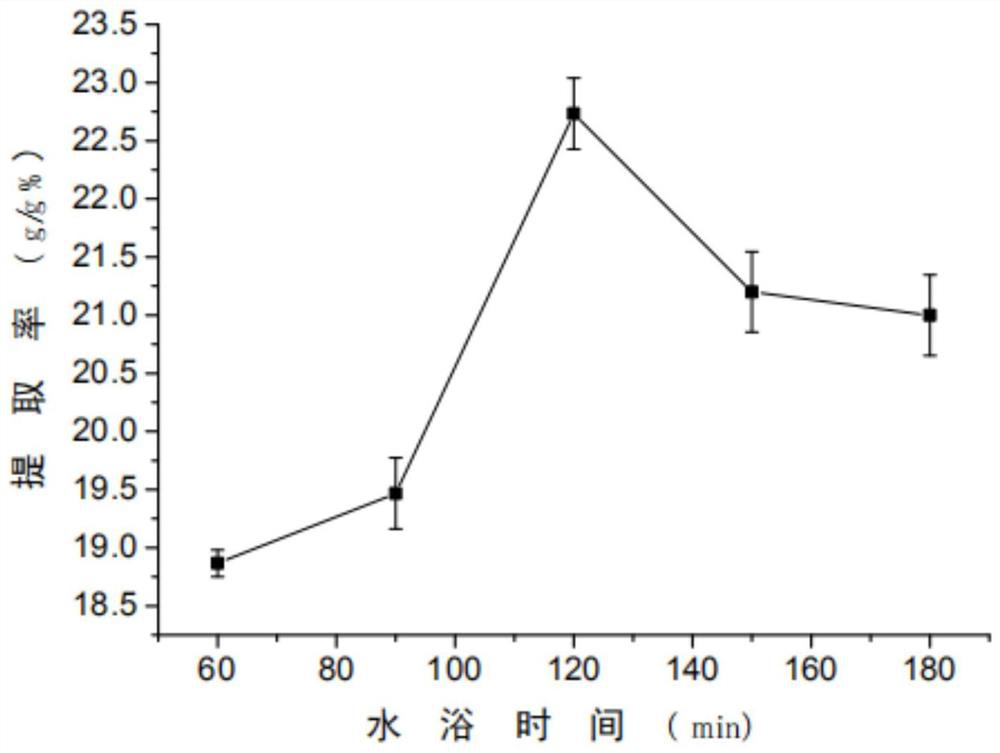

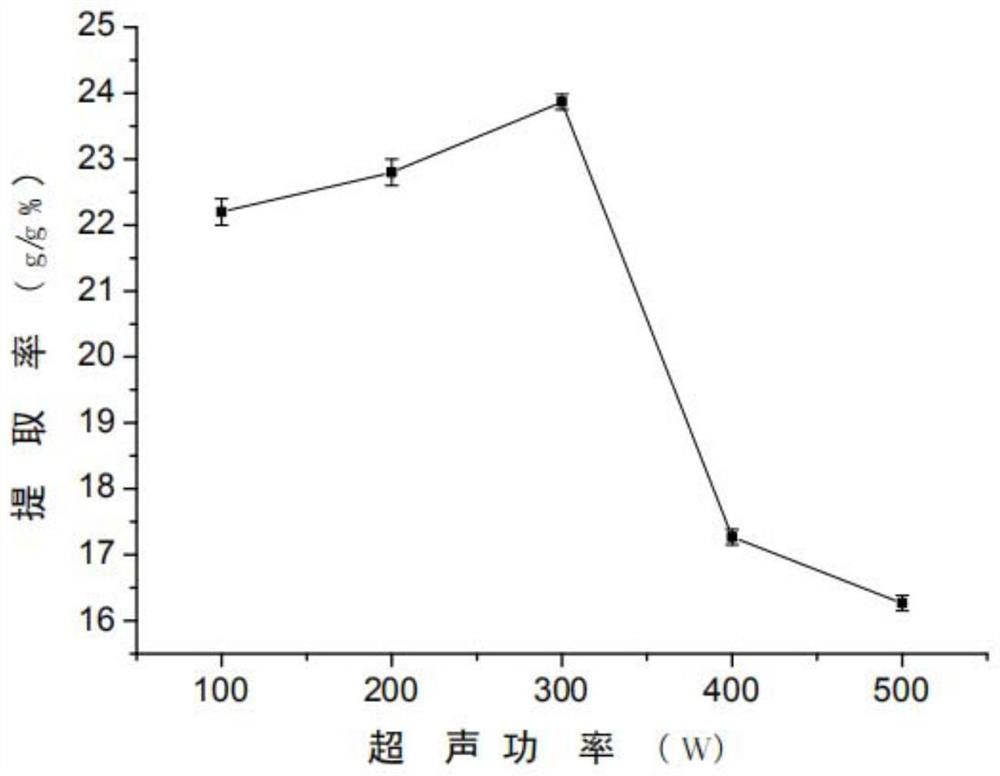

[0033] The extraction process optimization of embodiment 1 hijiki polysaccharide

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com