Scratch-resistant agent for highlight spraying-free PMMA and preparation method thereof

A scratch-resistant agent and spray-free technology, which is applied in the field of polymer materials, can solve the problems of poor compatibility, reduce the surface gloss of high-gloss materials, etc., achieve good compatibility, long-term excellent surface gloss, and improve scratch resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

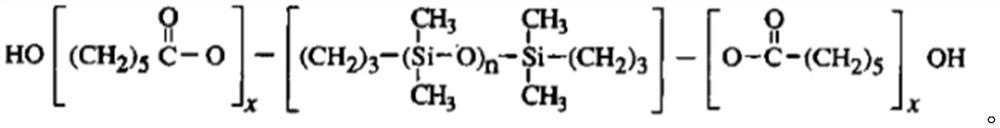

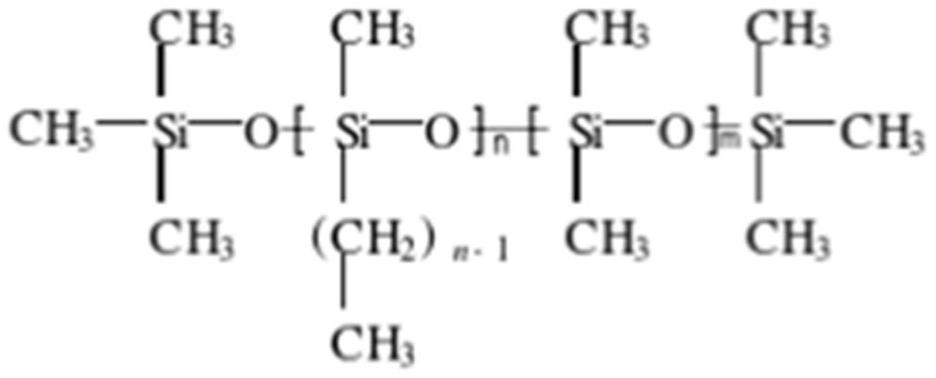

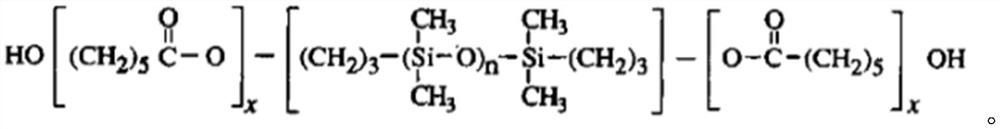

Method used

Image

Examples

Embodiment 1

[0032] A scratch-resistant agent for high-gloss spray-free PMMA, comprising the following components in parts by weight: 50 parts of nano-zirconia; 15 parts of modified polysiloxane; 35 parts of long-chain alkyl polysiloxane .

[0033] The preparation method includes the following steps: first weigh the modified polysiloxane and the long-chain alkyl polysiloxane in proportion, melt them in a melting tank at 100-120°C and mix them for 30 minutes, then add nano zirconium dioxide, stir and mix After 60 minutes, the mixed material was prepared; the mixed material was cooled by a steel belt fed with cooling water, then pulverized, and passed through a 6-mesh sieve to obtain a finished scratch-resistant agent.

[0034] A kind of PMMA composite material, in parts by weight, 3 parts of anti-scratch agents that embodiment 1 makes, 1 part of high-gloss black masterbatch, 0.3 part of antioxidant and Mitsubishi PMMA MF-001 are mixed homogeneously in mixer, then in Melting and blending ex...

Embodiment 2

[0036] A scratch-resistant agent for high-gloss spray-free PMMA, comprising the following components in parts by weight: 50 parts of nano-zirconia; 20 parts of modified polysiloxane; 30 parts of long-chain alkyl polysiloxane .

[0037] The preparation method includes the following steps: first weigh the modified polysiloxane and the long-chain alkyl polysiloxane in proportion, melt them in a melting tank at 100-120°C and mix them for 30 minutes, then add nano zirconium dioxide, stir and mix After 60 minutes, the mixed material was prepared; the mixed material was cooled by a steel belt fed with cooling water, then pulverized, and passed through a 6-mesh sieve to obtain a finished scratch-resistant agent.

[0038] A kind of PMMA composite material, in parts by weight, the anti-scratch agent that 3 parts of embodiment 2 are made, 1 part of high-gloss black masterbatch, 0.3 part of antioxidant and Mitsubishi PMMA MF-001 are mixed homogeneously in mixer, then in Melting and blend...

Embodiment 3

[0040] A scratch-resistant agent for high-gloss spray-free PMMA, comprising the following components in parts by weight: 40 parts of nano-zirconia; 20 parts of modified polysiloxane; 40 parts of long-chain alkyl polysiloxane .

[0041] The preparation method includes the following steps: first weigh the modified polysiloxane and the long-chain alkyl polysiloxane in proportion, melt them in a melting tank at 100-120°C and mix them for 30 minutes, then add nano zirconium dioxide, stir and mix After 60 minutes, the mixed material was prepared; the mixed material was cooled by a steel belt fed with cooling water, then pulverized, and passed through a 6-mesh sieve to obtain a finished scratch-resistant agent.

[0042] A kind of PMMA composite material, in parts by weight, the anti-scratch agent that 3 parts of embodiment 3 are made, 1 part of high-gloss black masterbatch, 0.3 part of antioxidant and Mitsubishi PMMA MF-001 are mixed homogeneously in mixer, then in Melting and blend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com