Heat accumulating type microwave heat treatment equipment and organic volatile gas treatment system

A microwave heat treatment and regenerative technology, which is applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of limiting the application of regenerative incinerators, volatile organic compound gas backwashing, and high overall construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

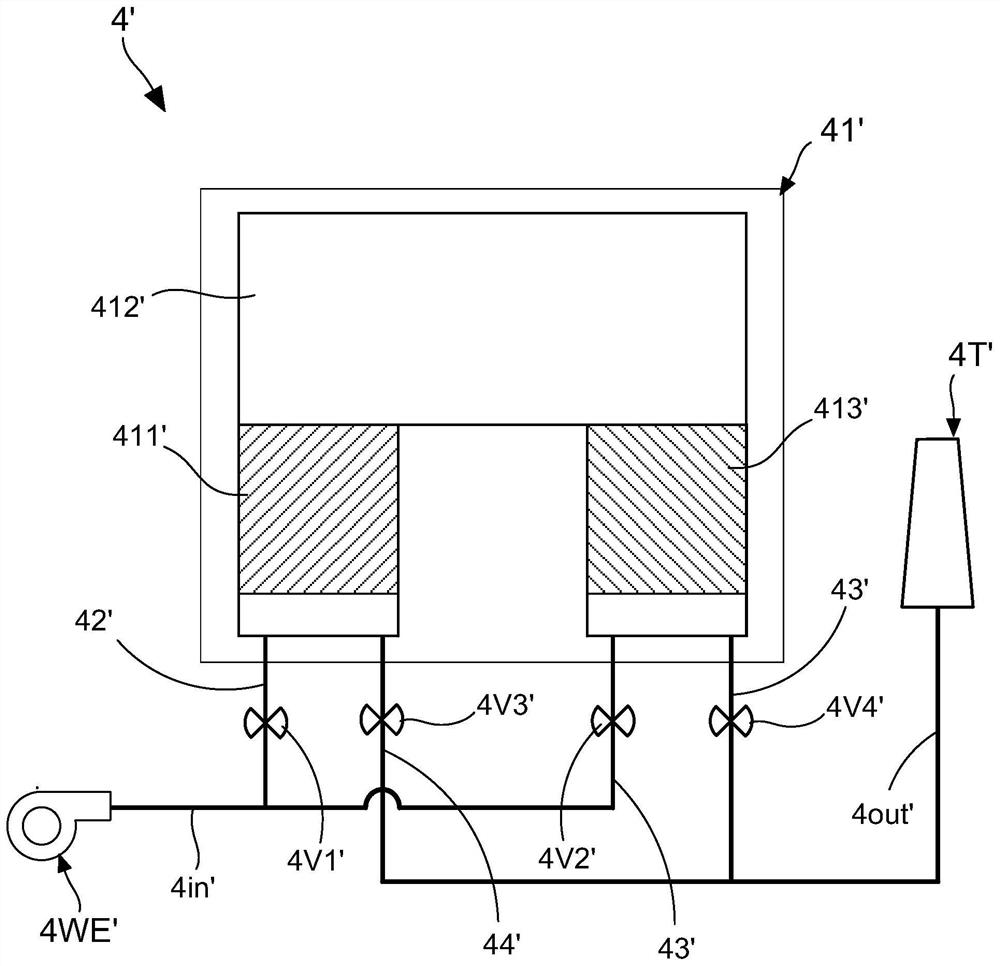

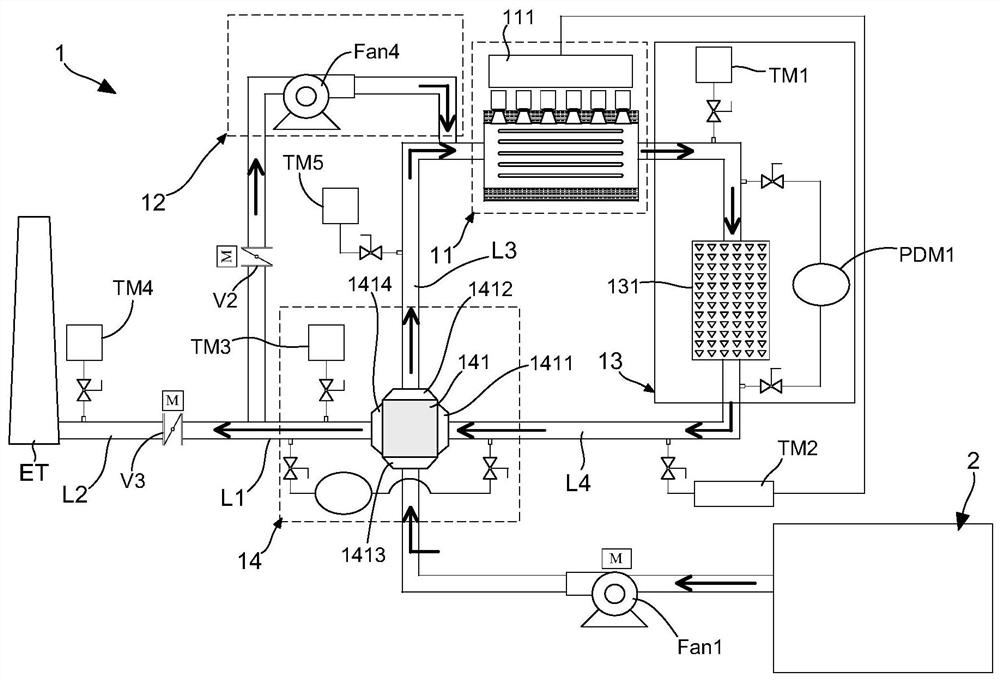

[0079] In order to more clearly describe a kind of regenerative microwave heat treatment equipment proposed by the present invention and an organic volatile gas treatment system having said regenerative microwave heat treatment equipment, the comparison of the present invention will be described in detail below with reference to the drawings. good example.

[0080] figure 2 A structure diagram showing an organic volatile gas treatment system including a regenerative microwave heat treatment device of the present invention. Such as figure 2 As shown, the organic volatile gas treatment system is mainly composed of a volatile organic compound gas input device 2 and the regenerative microwave heat treatment device 1 of the present invention; wherein, the volatile organic compound gas input device 2 may include a A volatile organic compound gas storage unit and a filter unit. Furthermore, the volatile organic compound gas input device 2 may also include a device or device with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com