Flexible tunable beam splitter and preparation method thereof

A beam splitter and flexible technology, applied in the field of flexible tunable beam splitter and its preparation, can solve problems such as restricting the market promotion and application of beam splitters, cumbersome preparation process, large technical resources, etc., and achieve excellent electrical regulation performance, Wide source of raw materials and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

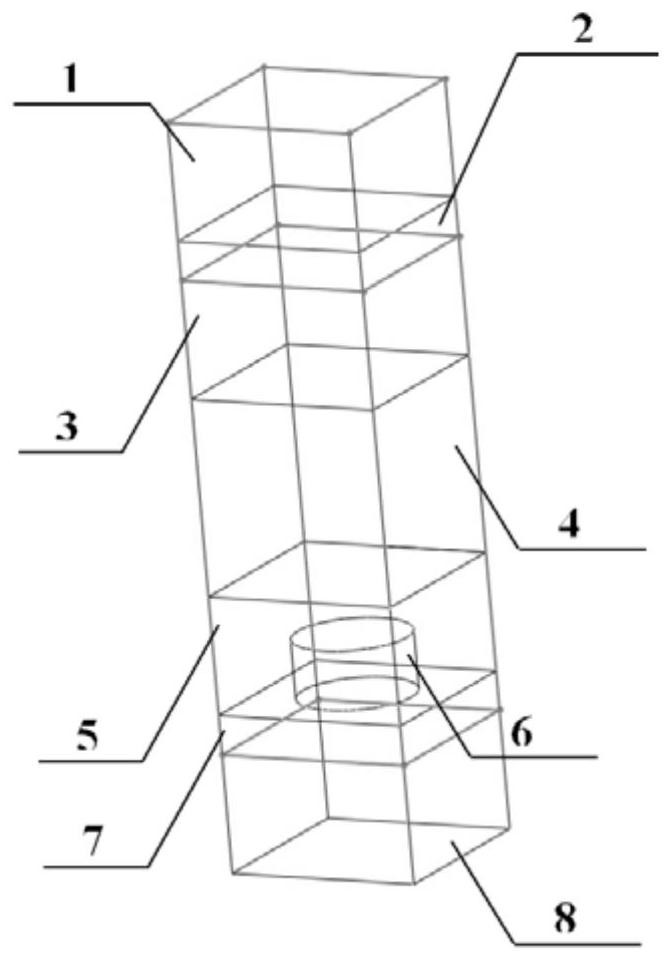

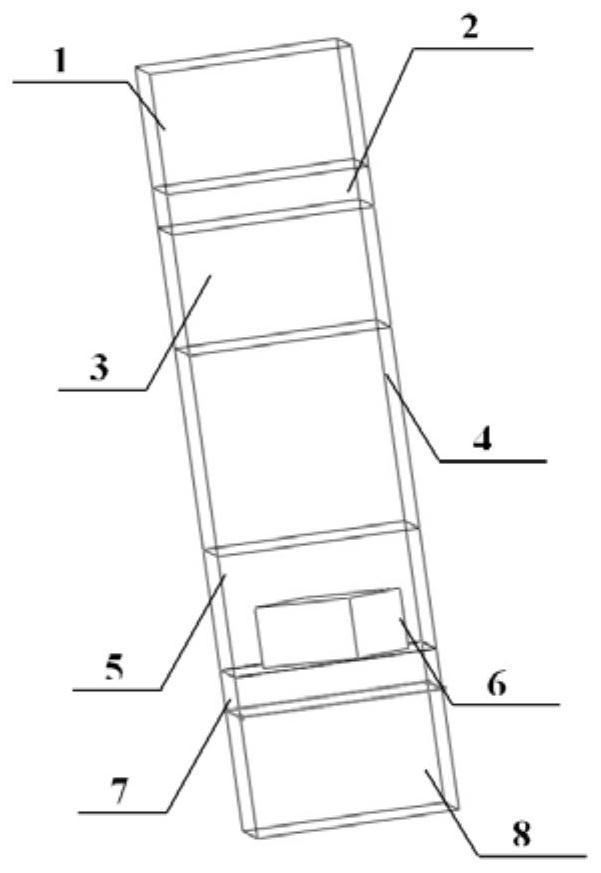

[0060] An aspect of the embodiments of the present invention provides a flexible tunable beam splitter based on a metasurface-electrochromic material, which includes an array of structural units, and each structural unit includes:

[0061] Flexible transparent substrate with a thickness of 2μm to 125μm;

[0062] a transparent bottom electrode, which is arranged on a flexible transparent substrate and has a thickness of 50nm to 150nm;

[0063] a metal functional layer, which is arranged on the transparent bottom electrode and includes a periodic nano-column / nano-rod array structure, with a thickness of 120nm-150nm;

[0064] an electrochromic layer, which is arranged on the transparent bottom electrode and coats the side and top surfaces of the metal nanostructure, with a thickness of 2 μm;

[0065] The electrolyte layer, which is arranged on the electrochromic layer, provides a channel for the transport of ions, and has a thickness of 40-60 μm;

[0066] The ion storage layer,...

Embodiment 2

[0094] Another embodiment of the present invention provides the aforementioned method for preparing a flexible tunable beam splitter based on a metasurface-electrochromic material, comprising:

[0095] Step S101, disposing a transparent bottom electrode on the flexible transparent substrate.

[0096] In a specific implementation, the transparent bottom electrode layer is formed on the flexible transparent substrate by using an optical coating technology; and / or the transparent bottom electrode layer is formed on the flexible transparent substrate by using a magnetron sputtering coating technology.

[0097] In step S102, a metal functional layer is provided on the transparent bottom electrode, and a periodic nano-column / nano-rod array structure is formed in the metal functional layer.

[0098] In a specific implementation, the metal functional layer is formed on the transparent bottom electrode by using electron beam evaporation coating technology.

[0099] In a specific imple...

Embodiment 3

[0114] The embodiments of the present invention provide the application of the aforementioned flexible tunable beam splitter based on the metasurface-electrochromic material in the preparation of an optical communication system, a nanophotonic device or an integrated optical system.

[0115] The technical solutions of the present invention will be further clearly and completely explained below with reference to the accompanying drawings and more specific embodiments.

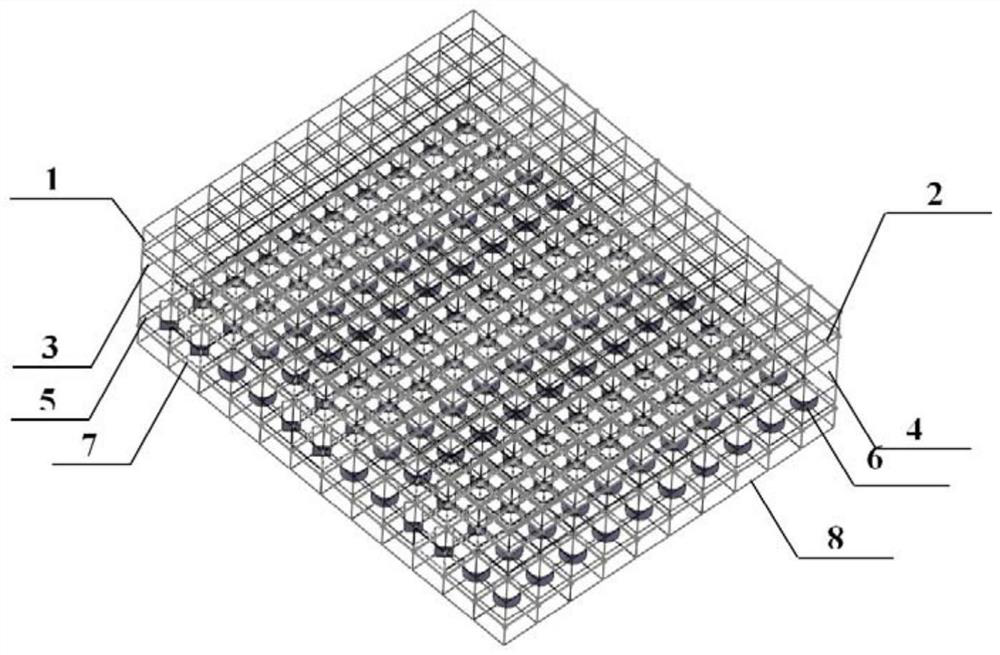

[0116] see figure 1As shown, a flexible tunable beam splitter based on a metasurface-electrochromic material in this embodiment includes gold nanopillars with designed diameters and gold nanopillars formed by alternately arranging gold nanorods in the manner of "AABB" / Nanorod array structure 6, electrochromic layer 5, electrolyte layer 4, ion storage layer 3, transparent top / bottom electrodes 2 / 7, flexible transparent upper / lower substrate 1 / 8. A beam of visible light (632.8 nm) polarized in the X-direction is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com