Submicron surface plasmon polariton beam splitter based on composite cavity structure

A surface plasmon and beam splitter technology, applied in the field of nanophotonics, can solve the problems of low beam splitting ratio, unfavorable high integration, reduced device design and processing flexibility, etc., to improve integration and beam splitting performance Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

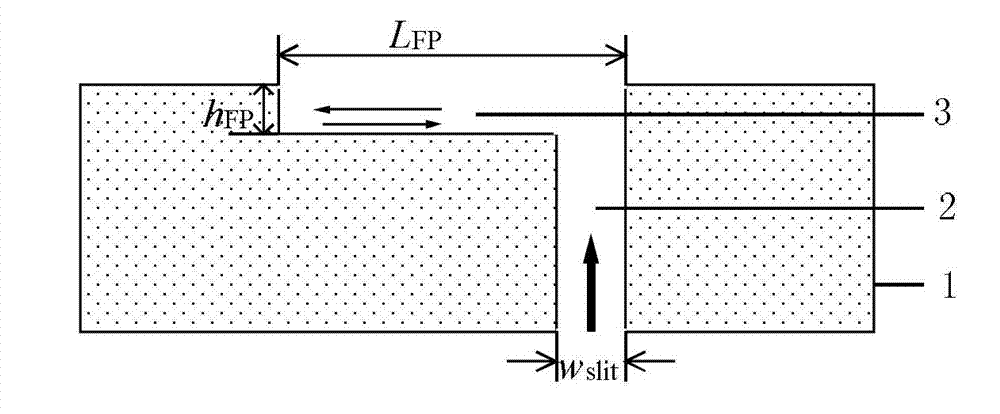

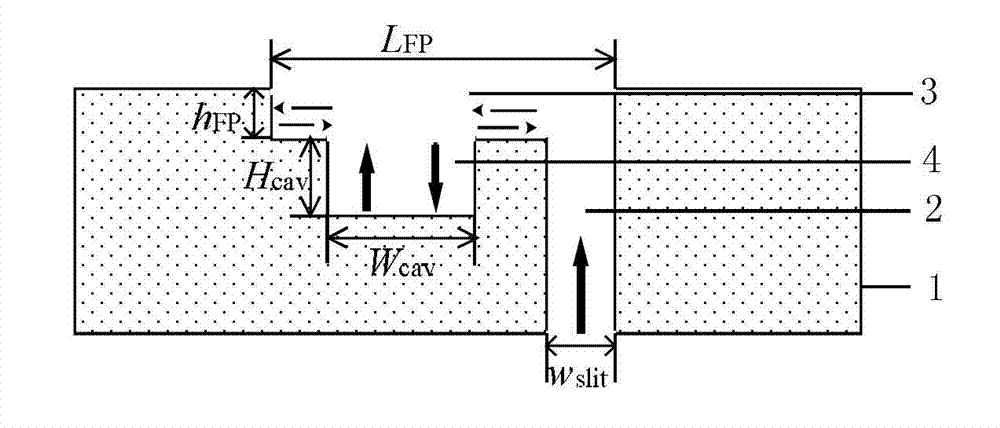

[0020] Such as figure 1 As shown, the nano-slit disposed on the metal film 1 and the nano-groove 3 on the left side of the nano-slit 2 form an asymmetric nano-single slit. An FP resonant cavity is formed between the left wall of the nanotrench and the right wall of the nanoslit. The metal film adopts a gold film, and the width of the nano-slit w slit =180nm, the length L of the FP cavity FP =790nm, the depth h of the nano-groove FP =120nm. Numerical simulations were carried out using the finite element method FEM. The dielectric constant of gold in the simulations as a function of wavelength was taken from the literature and developed by interpolation.

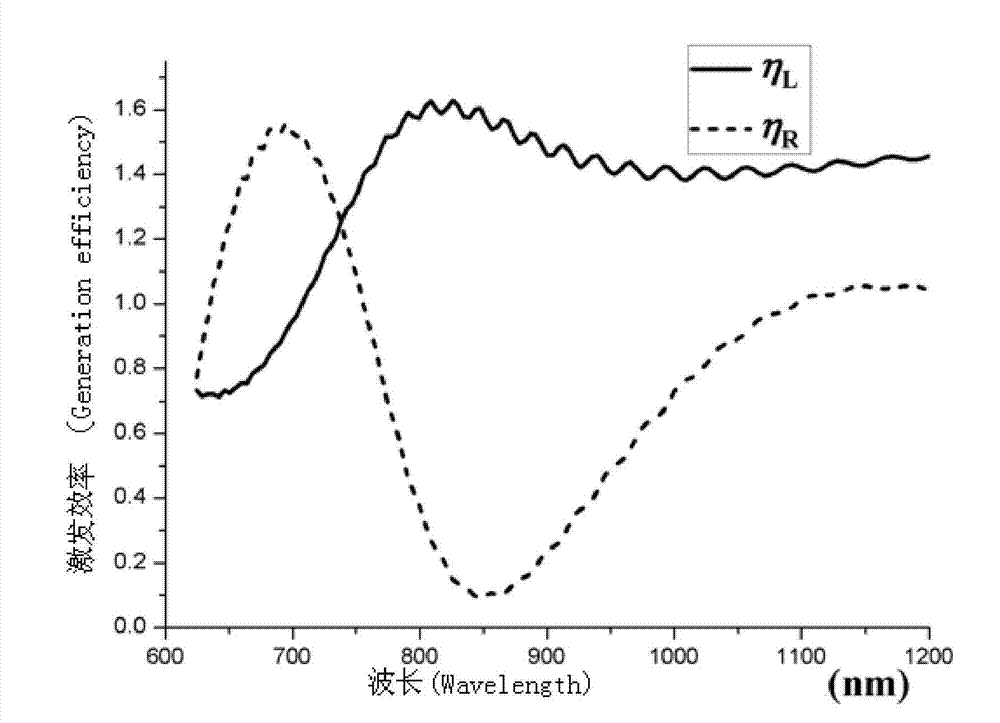

[0021] The simulation results are as figure 2 As shown in , it can be clearly seen that at λ=850nm, SPPs mainly propagate to the left. This is because the rightward propagating SPPs alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com