Stapling staple with anti-inflammatory function and preparation method thereof

A staple and function technology, applied in the field of staplers, can solve problems such as patient distress and inflammation, and achieve the effect of improving the quality of life

- Summary

- Abstract

- Description

- Claims

- Application Information

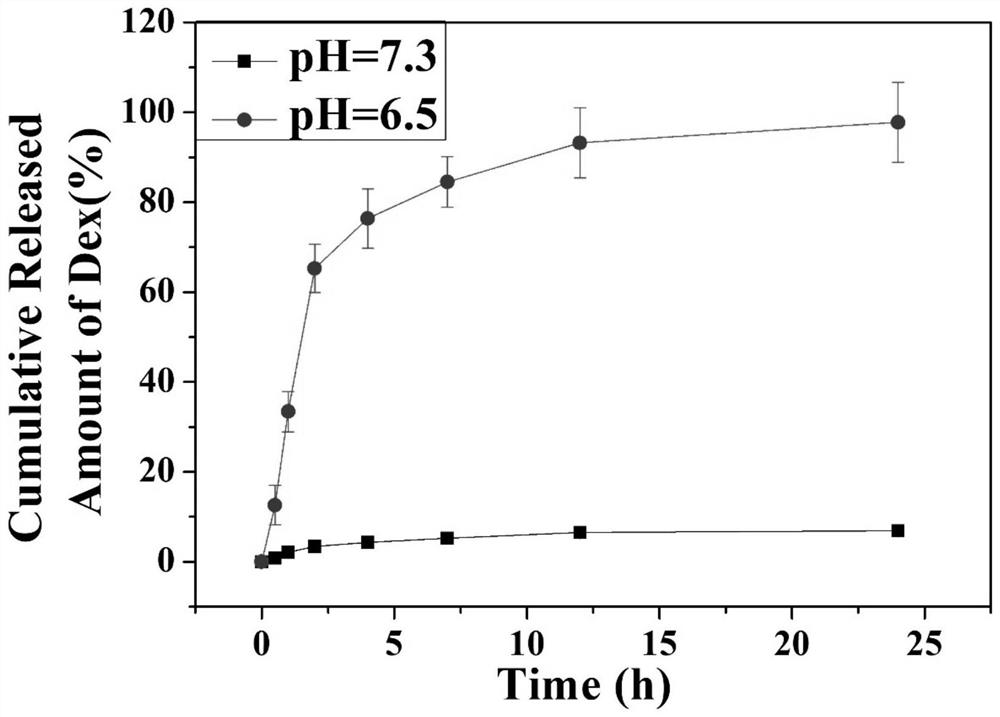

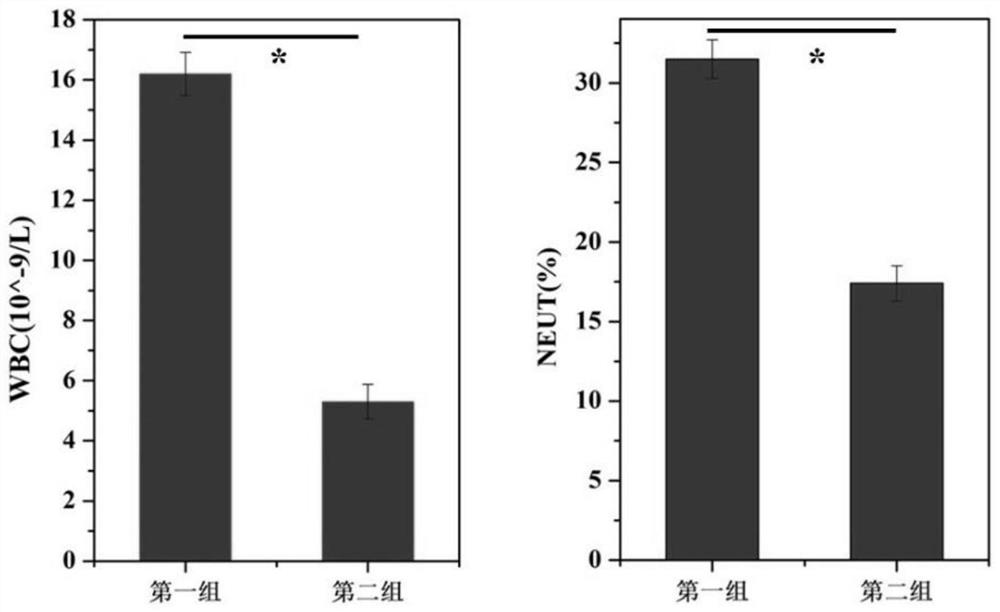

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

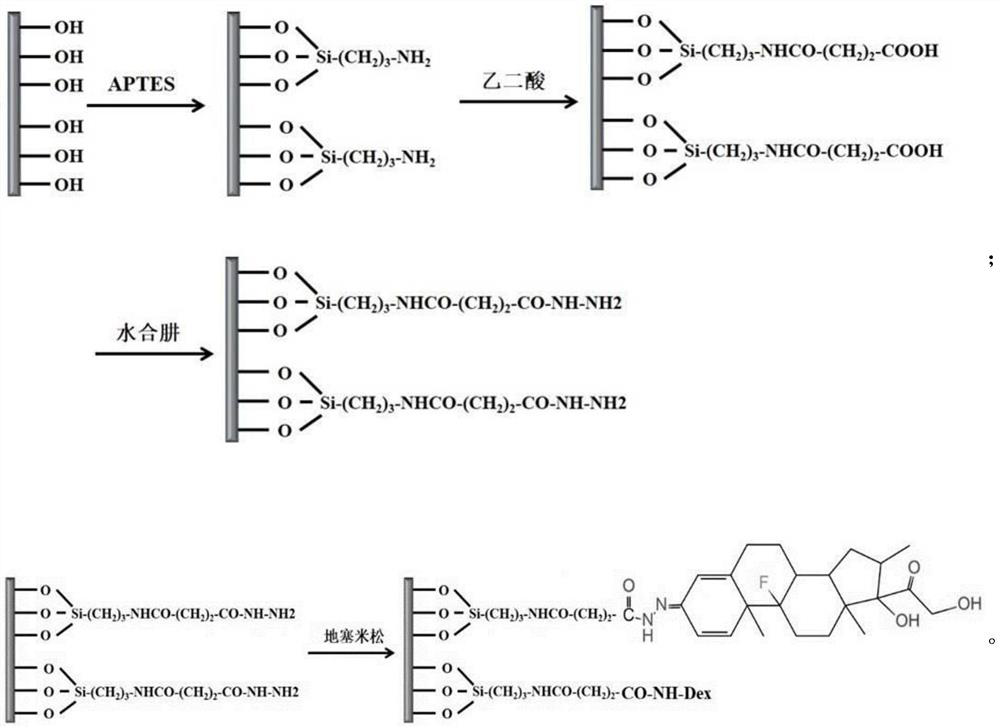

[0022] (1) Surface hydroxylation of staples

[0023] Put the staples in the EPT-02 plasma surface treatment instrument, control the temperature at 25°C, power 2.5kw, time 20min, the treatment atmosphere is vacuum conditions, the plasma is oxygen plasma, and carry out surface hydroxylation treatment on the staples;

[0024] (2) Surface hydrazide of staples

[0025] Soak the surface-hydroxylated staples in a saturated acetone solution of 3-aminopropyltriethoxysilane, heat to 65°C, and react for 24 hours. After the reaction, wash with ethanol and dry; then take oxalic acid , 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide are dissolved in water to prepare a mixed solution, wherein oxalic acid, 1-(3 -Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide in a molar ratio of 1:1:1, soak the previously treated staples in the mixed solution , reacted at room temperature for 24 hours, washed with deionized water and dried...

Embodiment 2

[0031] (1) Surface hydroxylation of staples

[0032] Put the staples in the EPT-02 plasma surface treatment instrument, control the temperature at 40°C, power 4kw, time 30min, the treatment atmosphere is vacuum condition, the plasma is oxygen plasma, and carry out surface hydroxylation treatment on the staples;

[0033] (2) Surface hydrazide of staples

[0034] Soak the surface-hydroxylated staples in a saturated acetone solution of 3-aminopropyltriethoxysilane, heat to 70°C, and react for 20 hours. After the reaction, wash with ethanol and dry; then take oxalic acid , 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide are dissolved in water to prepare a mixed solution, wherein oxalic acid, 1-(3 -Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide in a molar ratio of 1:1.2:0.8, soak the previously treated staples in the mixed solution , reacted at room temperature for 20 hours, washed with deionized water and drie...

Embodiment 3

[0038] (1) Surface hydroxylation of staples

[0039]Put the staples in the EPT-02 plasma surface treatment instrument, control the temperature at 10°C, power 5kw, time 40min, the treatment atmosphere is vacuum conditions, the plasma is oxygen plasma, and carry out surface hydroxylation treatment on the staples;

[0040] (2) Surface hydrazide of staples

[0041] Soak the surface-hydroxylated staples in a saturated acetone solution of 3-aminopropyltriethoxysilane, heat to 80°C, and react for 30 hours. After the reaction, wash with ethanol and dry; then take oxalic acid , 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide are dissolved in water to prepare a mixed solution, wherein oxalic acid, 1-(3 -Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide in a molar ratio of 1:0.8:1, soak the previously treated staples in the mixed solution , reacted at room temperature for 30 hours, washed with deionized water and dried,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com