Electric spark machining equipment

A processing equipment and EDM technology, which is applied in the field of EDM equipment, can solve the problems of large differences in equipment use experience, non-adjustable height of EDM equipment, and inconvenient adjustment, achieving simple structure, good user experience, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

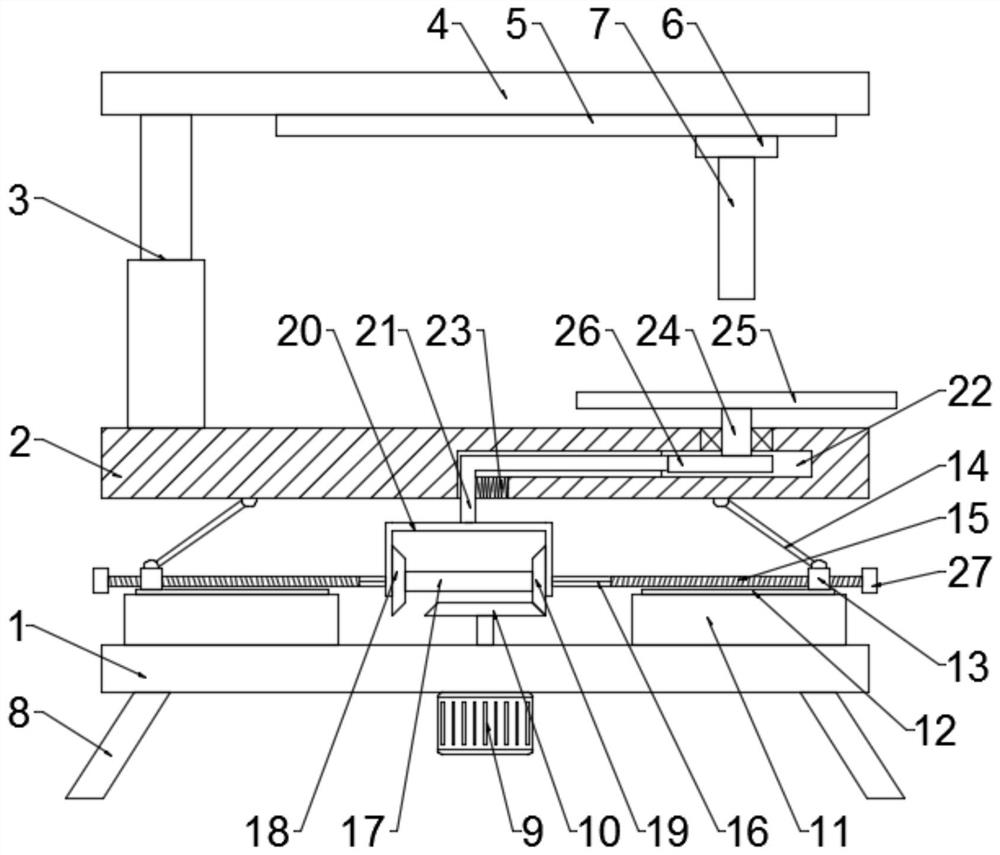

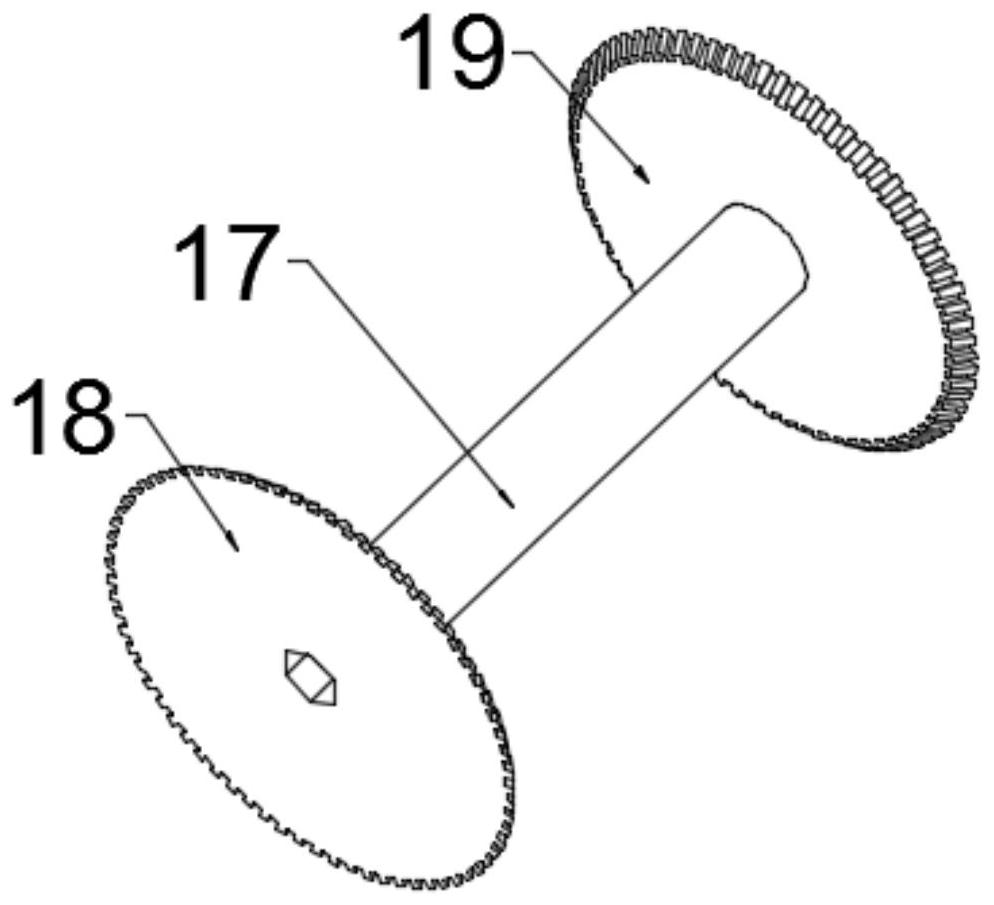

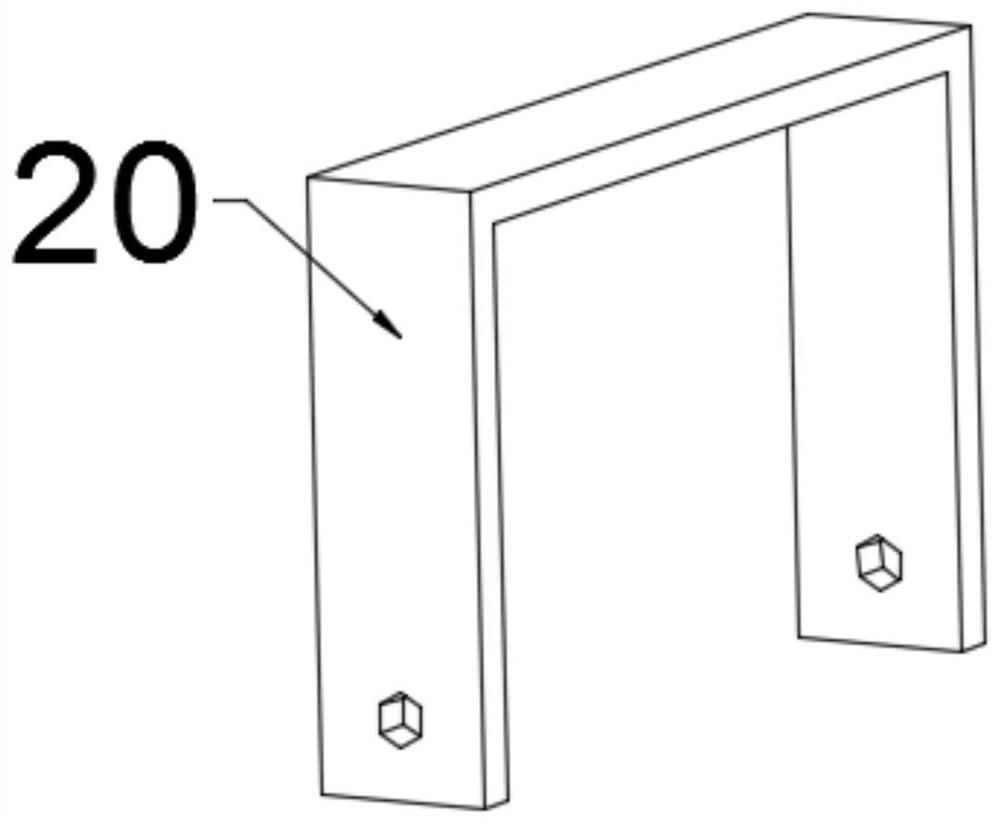

[0021] Example 1: Please refer to Figure 1-3 , a kind of electrical discharge machining equipment, comprising a lower base plate 1 and an upper base plate 2, a longitudinal drive device 3 is fixedly connected to the left side of the top of the upper base plate 2, an upper beam 4 is fixedly connected to the top of the longitudinal drive device 3, and an upper beam 4 is fixedly connected below the upper beam 4 The first chute 5, the horizontal driving device 6 is slidably connected to the lower part of the first chute 5, the electric discharge machining assembly 7 is fixedly connected to the lower part of the horizontal driving device 6, and the left and right symmetrical support frames 8 are fixedly connected to the bottom of the lower bottom plate 1. A motor 9 is fixedly connected to the lower middle part of the base plate 1, and the axis of the motor 9 runs through the lower base plate 1 and is connected with a driving bevel gear 10;

[0022] When in use, the position contro...

Embodiment 2

[0033] Embodiment two: refer to Figure 1-3 , a kind of electrical discharge machining equipment, comprising a lower base plate 1 and an upper base plate 2, a longitudinal drive device 3 is fixedly connected to the left side of the top of the upper base plate 2, an upper beam 4 is fixedly connected to the top of the longitudinal drive device 3, and an upper beam 4 is fixedly connected below the upper beam 4 The first chute 5, the horizontal driving device 6 is slidably connected to the lower part of the first chute 5, the electric discharge machining assembly 7 is fixedly connected to the lower part of the horizontal driving device 6, and the left and right symmetrical support frames 8 are fixedly connected to the bottom of the lower bottom plate 1. A motor 9 is fixedly connected to the lower middle part of the base plate 1, and the axis of the motor 9 runs through the lower base plate 1 and is connected with a driving bevel gear 10;

[0034] When in use, the position control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com