Alkali-resistant impermeable waterproof slurry and construction process thereof

A technology of waterproof slurry and construction technology, which is applied in construction, building structure, covering/lining, etc., can solve the problem of ubiquitous alkali problem that cannot be fundamentally solved, and achieves compact structure, good alkali resistance, and good seawater resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] An alkali-resistant and impermeable waterproof slurry, comprising a surface layer slurry and a bottom layer slurry, and the bottom layer slurry includes the following components:

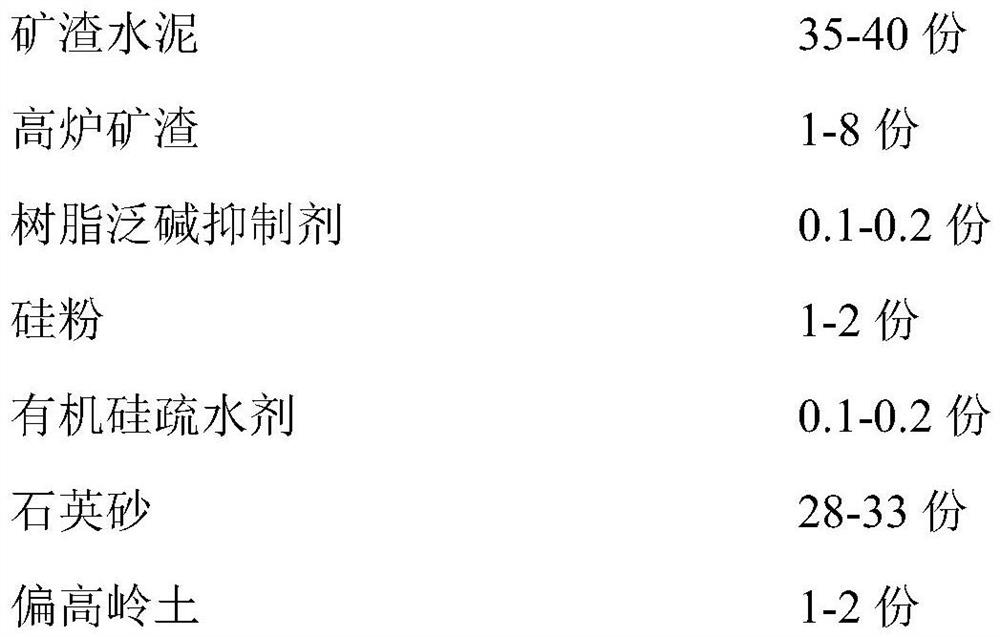

[0081] Powder A, the powder A includes the following compositions by mass:

[0082]

[0083] A liquid preparation, the liquid preparation includes the following components in parts by mass:

[0084]

[0085] The surface layer slurry includes the following components:

[0086] Powder B, the composition and content of the powder B are the same as those of the powder A, the only difference is that the slag cement in the powder A is replaced by the low-alkali sulfoaluminate cement of the same quality and the same label.

[0087] The liquid agent, the composition and content of the liquid agent and the liquid agent in the bottom layer slurry are the same.

[0088] The construction process of the above-mentioned alkali-resistant and impermeable waterproof slurry is (the measured temperature...

Embodiment 2

[0094] An alkali-resistant and impermeable waterproof slurry, comprising a surface layer slurry and a bottom layer slurry, and the bottom layer slurry includes the following components:

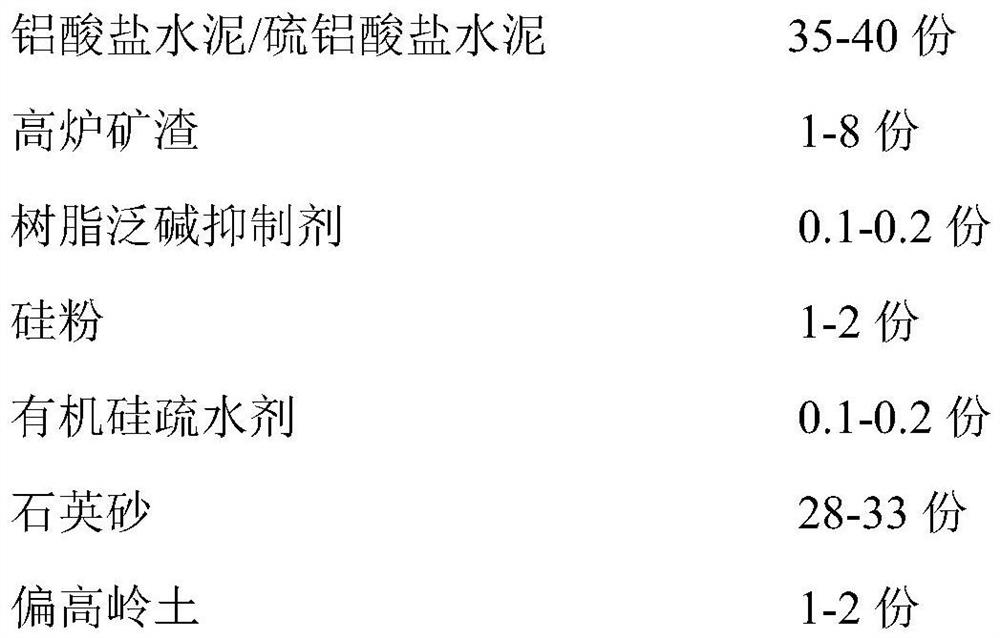

[0095] Powder A, the powder A includes the following compositions by mass:

[0096]

[0097] A liquid preparation, the liquid preparation includes the following components in parts by mass:

[0098]

[0099] The surface layer slurry includes the following components:

[0100] Powder B, the composition and content of the powder B are the same as those of the powder A, the only difference is that the slag cement in the powder A is replaced by the low-alkali sulfoaluminate cement of the same quality and the same label.

[0101] The liquid agent, the composition and content of the liquid agent and the liquid agent in the bottom layer slurry are the same.

[0102] The construction process of the above-mentioned alkali-resistant and impermeable waterproof slurry is (the measured temperature...

Embodiment 3

[0108] An alkali-resistant and impermeable waterproof slurry, comprising a surface layer slurry and a bottom layer slurry, and the bottom layer slurry includes the following components:

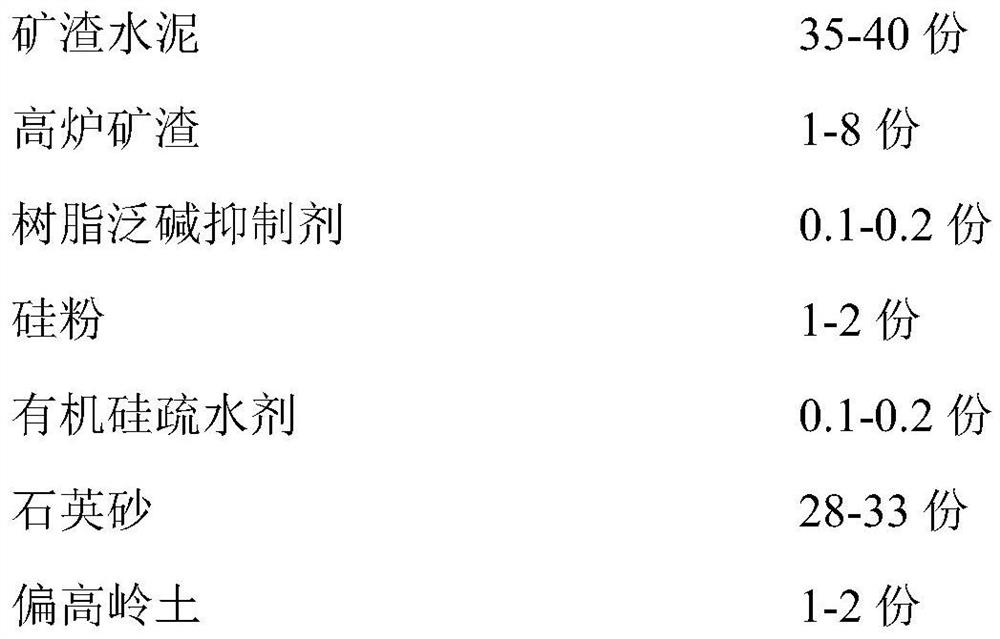

[0109] Powder A, the powder A includes the following compositions by mass:

[0110]

[0111] A liquid preparation, the liquid preparation includes the following components in parts by mass:

[0112]

[0113] The surface layer slurry includes the following components:

[0114] Powder B, the composition and content of the powder B are the same as those of the powder A, the only difference is that the slag cement in the powder A is replaced by ordinary aluminate cement of the same quality and the same label.

[0115] The liquid agent, the composition and content of the liquid agent and the liquid agent in the bottom layer slurry are the same.

[0116] The construction process of the above-mentioned alkali-resistant and impermeable waterproof slurry is (the measured temperature of the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com