Acrylic resin, low-VOC acrylic coating material and preparation method of acrylic resin

A technology of acrylic resin and methacrylic acid, which is applied in the field of chemical coatings, can solve the problems of uneven molecular weight of resin, unreachable link density, affecting chemical resistance, etc., and achieves improvement of ambient air quality, full hardness and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

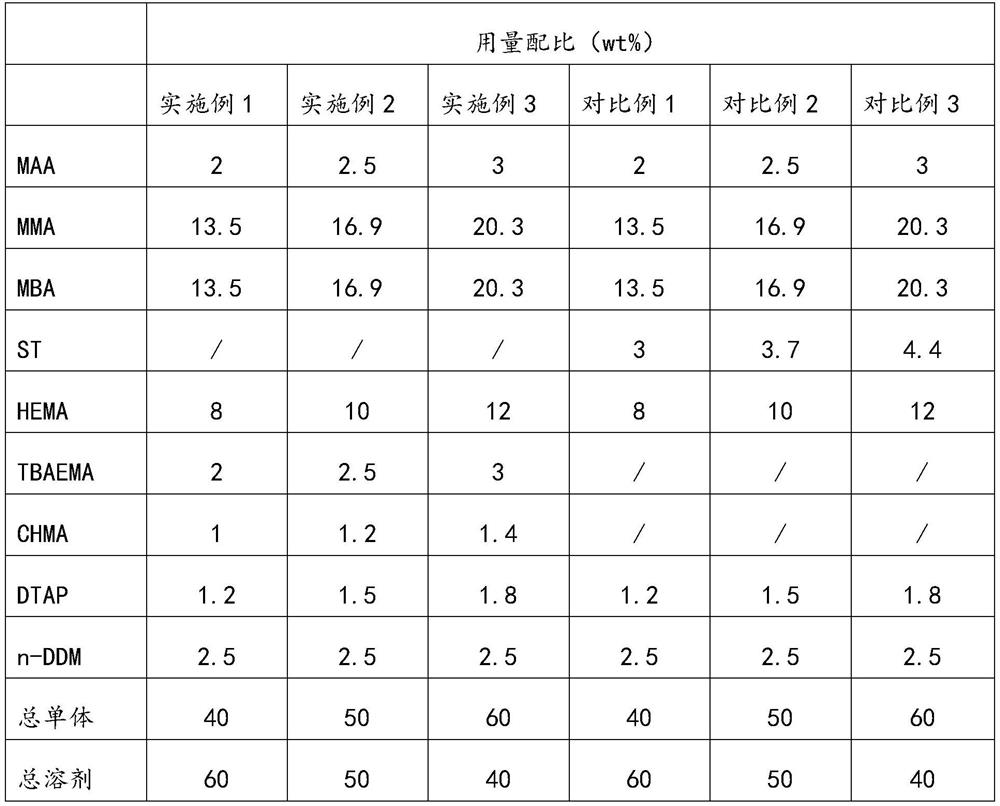

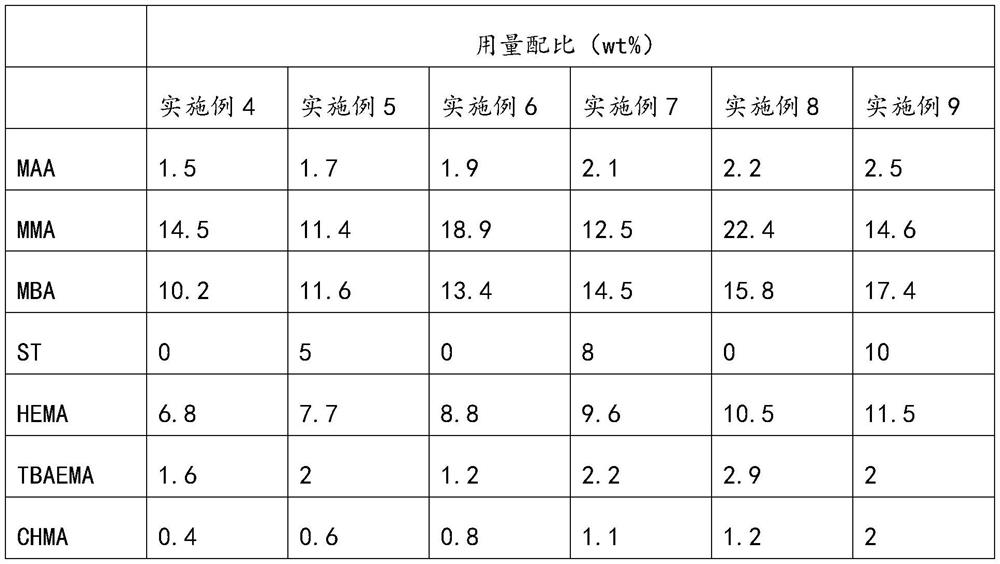

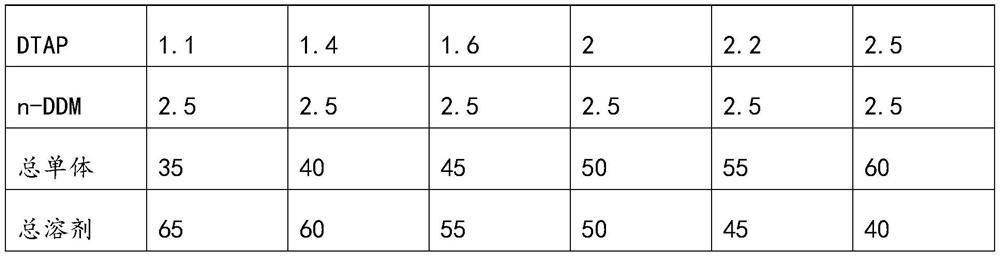

Examples

Embodiment 1

[0031] A kind of acrylic resin, its formula comprises base material and initiator;

[0032] Among them, the base formula is: 2wt% methacrylic acid (MAA), 13.5wt% methyl methacrylate (MMA), 13.5wt% butyl methacrylate (MBA), 8wt% hydroxyethyl methacrylate (HEMA ), 2wt% tert-butylaminoethyl methacrylate (TBAEMA) and 1wt% cyclohexyl methacrylate (CHMA), and the balance is solvent; solvent is propylene glycol methyl ether acetate;

[0033] The initiator is 1.2wt% di-tert-amyl peroxide (DTAP) based on the mass of the base material.

[0034] The preparation method of above-mentioned acrylic resin comprises the steps:

[0035] (1) Solvent and 0.1wt% initiator in terms of base material are added in the reactor equipped with thermometer, water trap, condenser and peristaltic pump according to the formula, the temperature is raised to reflux, and the temperature is 180 ℃, start to drop single The solid mixture and 0.9wt% initiator based on the base material were added for 3 hours, and ...

Embodiment 2

[0058] The difference with Example 1 is that the monomer formula ratio is consistent, and the monomer concentration is 50wt%, and the specific formula is shown in Table 1; all the other technical characteristics are the same as Example 1.

Embodiment 3

[0060] The difference with Example 1 is that the monomer formula ratio is consistent, and the monomer concentration is 60wt%, and the specific formula is shown in Table 1; all the other technical characteristics are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com