Method for extracting and recovering zinc from high leaching residue flotation tailing water

A technology of flotation tailings and high leaching slag, which is applied in the field of zinc extraction and recovery, can solve the problems of loss of extraction zinc transfer volume, difficulty in production system balance, increase of silver system volume, etc., to reduce the amount of carried oil, ensure time, Effect of reducing zinc loss by washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

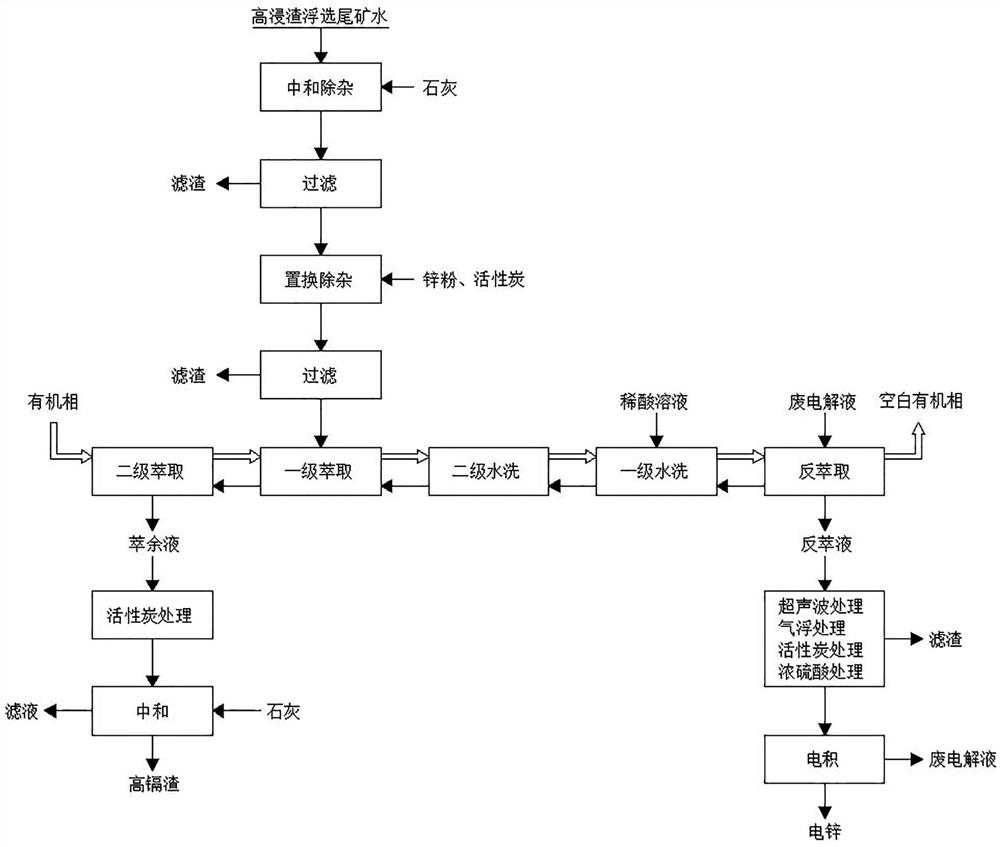

[0019] Embodiment 1: as figure 1 Shown, a kind of method for extracting and recovering zinc from high leaching slag flotation tailings water, it comprises pre-extract treatment, secondary extraction, secondary water washing, strip extraction, strip treatment and raffinate treatment steps, the The above-mentioned pre-extraction treatment includes the following steps: (1) neutralization and removal of impurities: adding lime to the high leaching residue flotation tailings water, adjusting the pH value to 5.5, filtering and removing the filter residue, and obtaining the neutralization filtrate; (2) replacement Adsorption and impurity removal: Add zinc powder and activated carbon to the neutralization filtrate, heat to 38°C, and perform a displacement reaction for 50 minutes. Add 1.0-1.5kg of activated carbon to each cubic meter of neutralization filtrate. 2+ Ions and Cu 2+ Determine the content of ions, add zinc powder replacement reaction to neutralize the water-soluble Ca in t...

Embodiment 2

[0020] Embodiment 2: as figure 1 Shown, a kind of method for extracting and recovering zinc from high leaching slag flotation tailings water, it comprises pre-extract treatment, secondary extraction, secondary water washing, strip extraction, strip treatment and raffinate treatment steps, the The above-mentioned pre-extraction treatment includes the following steps: (1) neutralization and removal of impurities: adding lime to the high leaching residue flotation tailings water, adjusting the pH value to 6, filtering and removing the filter residue, and obtaining the neutralization filtrate; (2) replacement Adsorption and impurity removal: Add zinc powder and activated carbon to the neutralization filtrate, heat to 36°C, and perform a displacement reaction for 55 minutes. Add 1.0-1.5kg of activated carbon to each cubic meter of neutralization filtrate, and the amount of zinc powder depends on the Ca in the neutralization filtrate. 2+ Ions and Cu 2+ Determine the content of ions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com