Grouting anchor rod cable combined beam for advanced supporting of deep broken surrounding rock and support method

A technology of grouting bolts and composite beams, which is applied in the directions of supporting the roof beams of the mine roof, installing bolts, and earth-moving drilling, etc. Guiding on-site grouting construction, inability to install pallets, etc., to improve the stress state of surrounding rock, improve integrity and self-supporting force, and avoid blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

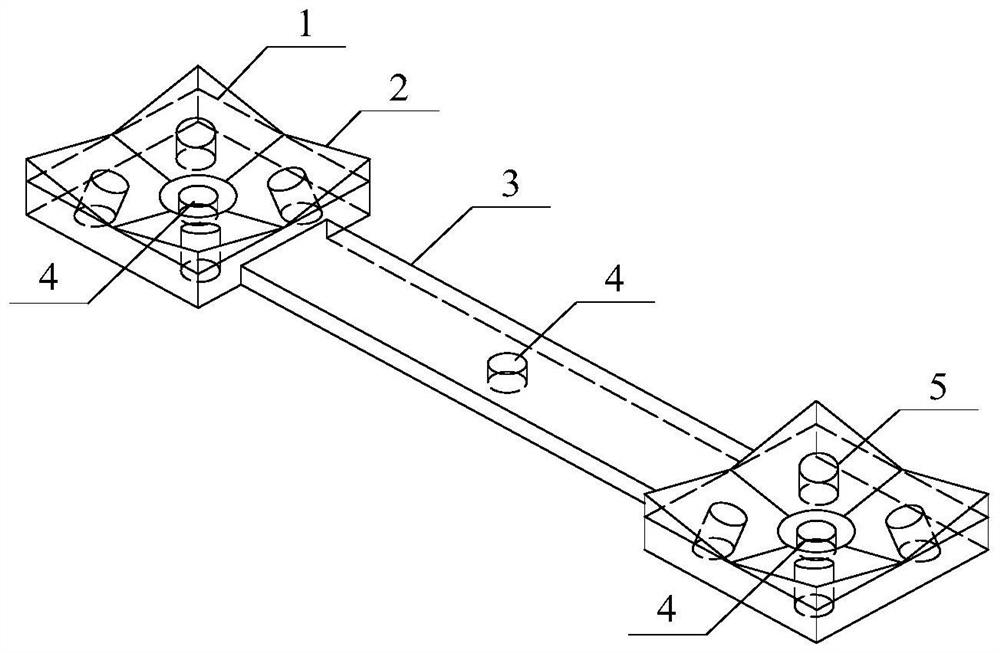

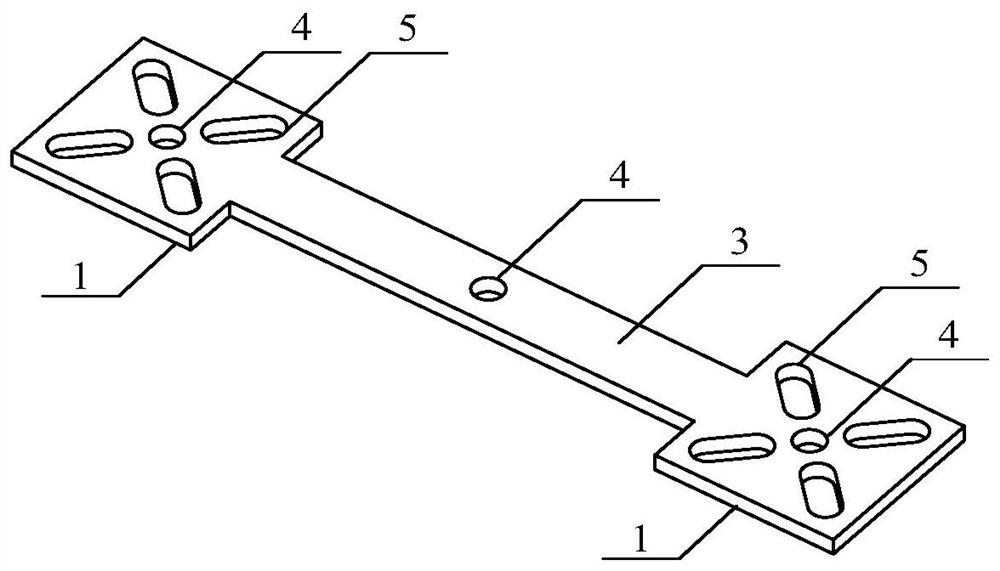

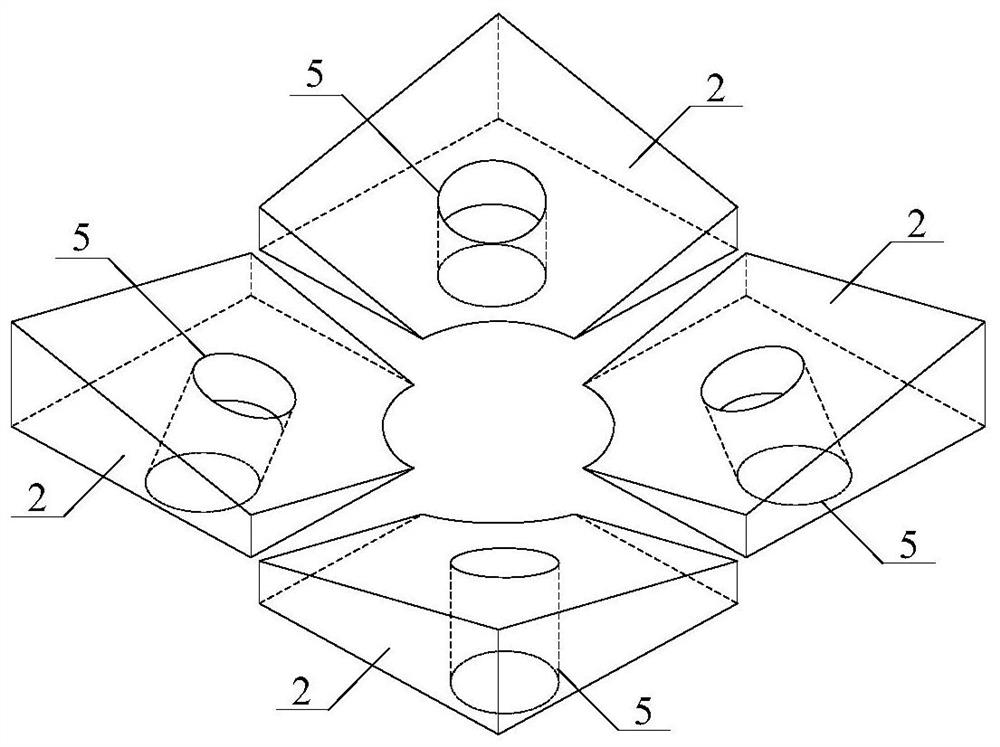

[0075] The pallet used in the composite beam of the present invention refers to image 3 As shown, what is shown in the figure is the state that four pallets are arranged on the guard plate 1, as can be seen from the figure, the pallet is a wedge-shaped spacer 2, and the upper and lower sides of the wedge-shaped spacer 2 are planes and slopes respectively. The wedge-shaped spacer 2 is provided with an anchor rod hole 5, and the angle of the slope of the wedge-shaped spacer 1 should ensure that when the pallet is in use, the anchor rod is arranged vertically to the pallet slope, that is to say, the anchor rod hole 5 is perpendicular to the pallet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com