Ultraviolet exposure method of volume holographic Bragg reflector

A Bragg mirror and exposure method technology, applied in the optical field, can solve the problems of difficult synchronization of environmental vibration, multiple fixing and operation of devices, and complexity, and achieve the effects of precise control, avoidance of uncertainty, and accurate cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

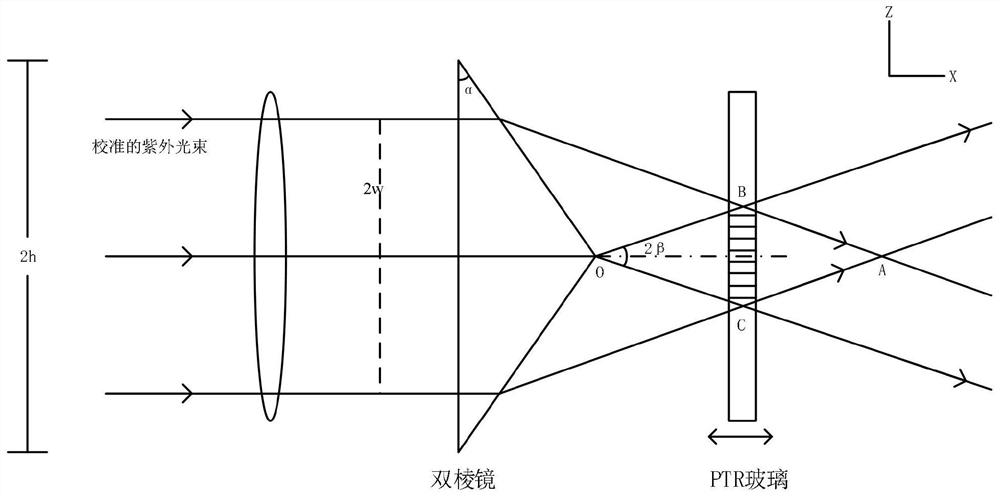

[0031] Experimental device such as figure 1 As shown, the recording material used to make the grating is photothermorefractive PTR glass, and the surface area of the PTR glass sample used is 7mm X 7mm, and the thickness is 2mm. A He-Cd laser with output power of 50mW is used as the ultraviolet exposure light source of the grating, and the output wavelength is 325nm, and the refractive index of the grating material at this wavelength is 1.4817. The output ultraviolet laser is firstly expanded (the magnification of the beam expander is adjustable from 1X to 10X), and a small hole diaphragm is placed on the focal plane of the beam expander for spatial filtering. The stability and uniformity of the spot largely determine the Fabrication properties of volume gratings.

[0032] UV exposure of volume holographic Bragg gratings is carried out as follows:

[0033] (1) Fix a double prism with side angle α.

[0034] (2) Use a beam of ultraviolet laser with a wavelength of 325nm to e...

Embodiment 2

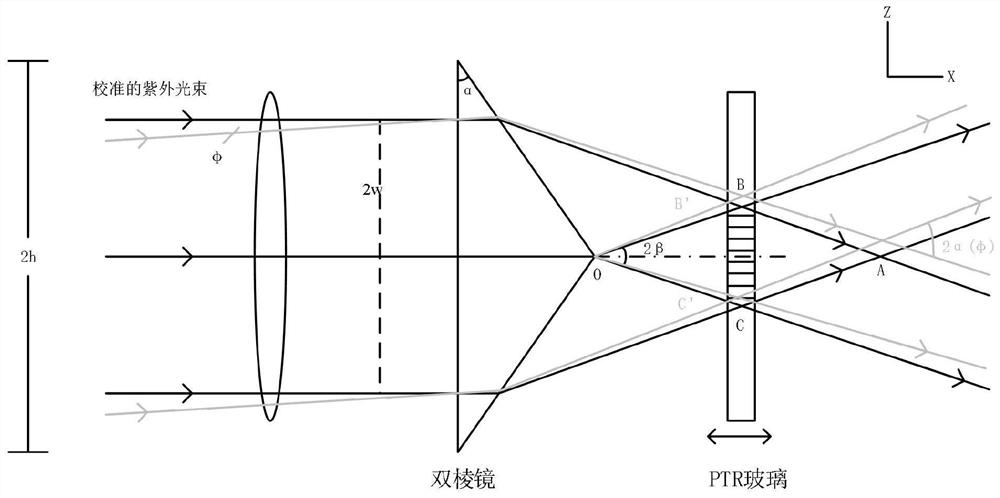

[0042] Experimental device such as figure 2 As shown, the recording material used to make the grating is photothermorefractive PTR glass, and the surface area of the PTR glass sample used is 7mm X 7mm, and the thickness is 2mm. A He-Cd laser with output power of 50mW is used as the ultraviolet exposure light source of the grating, and the output wavelength is 325nm, and the refractive index of the grating material at this wavelength is 1.4817. The output ultraviolet laser is firstly expanded (the magnification of the beam expander is adjustable from 1X to 10X), and a small hole diaphragm is placed on the focal plane of the beam expander for spatial filtering. The stability and uniformity of the spot largely determine the Fabrication properties of volume gratings.

[0043] UV exposure of volume holographic Bragg gratings is carried out as follows:

[0044] (1) Fix a double prism with side angle α.

[0045](2) Use a beam of ultraviolet laser with a wavelength of 325nm to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com