Novel instant pudding powder and preparation method

A pudding powder, instant technology, applied in the field of food processing, can solve the problems of bad taste, low water separation rate, low solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention develops an instant pudding powder product, because the dissolubility of carrageenan and konjac gum is relatively poor, so add other soluble hydrophilic colloid instant agar to replace part of carrageenan and konjac gum, so that the final product can obtain better Solubility. The test process used is as follows:

[0023] Recipe and results:

[0024] Formulation and result of Table 1 Test 1

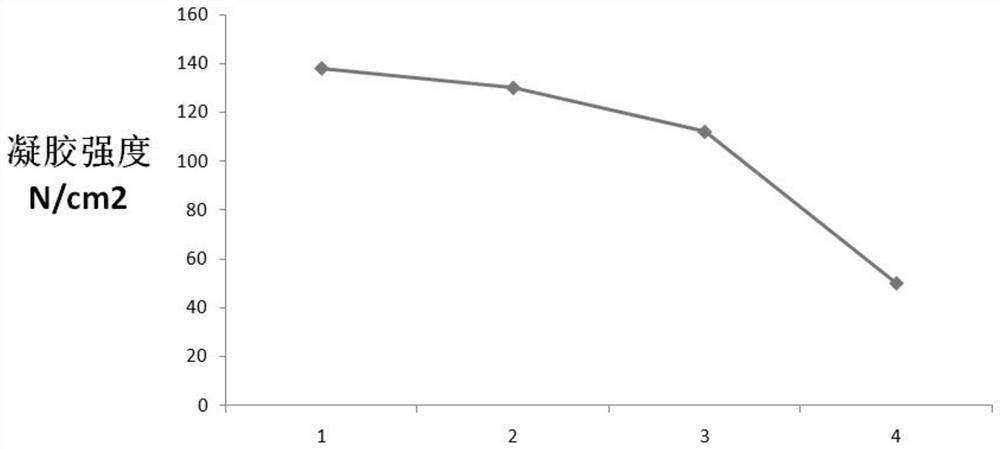

[0025] serial number 1 2 3 4 Whole milk powder / g 3 3 3 3 White sugar / g 4.5 4.5 4.5 4.5 Agar (D700) / g 0.3 0 0.3 0.3 Konjac gum / g 0.35 0.4 0.2 0.2 Carrageenan / g 0.25 0.25 0.1 0.15 Gel strength N / cm 2

177 201

[0026] Through the above four sets of tests, it was found that the solubility of No. 3 and No. 4 was significantly better than that of No. 1 and No. 2. After stirring the samples of No. 1 and No. 2 evenly, it was found that there were insoluble granular objects at the bottom. N...

Embodiment 2

[0048] 1 Raw material formula:

[0049] materials Weight (kg) Proportion (%) White sugar 580 58 whole milk powder 380 38 agar 17.9 1.79 Konjac Gum 12.8 1.28 carrageenan 9.3 0.93 Total 1000 100

[0050]Because carrageenan and konjac gum can meet the needs of pudding taste after mixing, but the solubility is poor, so consider using high gel strength instant agar to replace part of carrageenan and konjac gum to achieve both high solubility and high-quality pudding taste product. It can be seen from the table that white sugar has no obvious effect on the hardness of pudding, and the amount of milk powder added will affect the hardness of pudding powder, which is positively correlated. The higher the protein content of pudding, the higher the final gel strength.

[0051] 2 Preparation method: weigh the material according to the raw material formula, put the weighed material into the mixer and mix for 30 minutes (1000r / min...

Embodiment 3

[0055] 1 Raw material formula:

[0056] materials Weight (kg) Proportion (%) White sugar 580 58 whole milk powder 380 38 agar 17.5 1.75 Konjac Gum 13 1.3 carrageenan 9.5 0.95 Total 1000 100

[0057] 2 Preparation method: Weigh the materials according to the raw material formula, put the weighed materials into the mixer and mix them for 30 minutes (1000r / min), and quantitatively pack the mixed materials: 16g / bag.

[0058] 3 Edible method: Use hot water above 70°C, mix according to the ratio of pudding powder and hot water at a ratio of 4:25, stir and dissolve, and eat after cooling and solidifying.

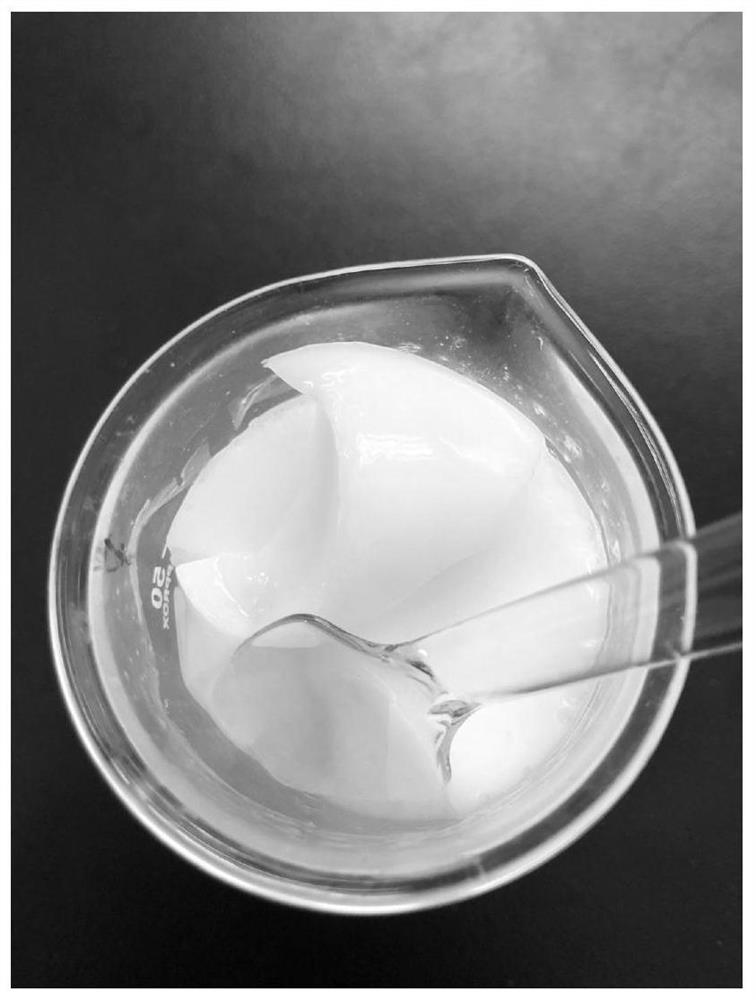

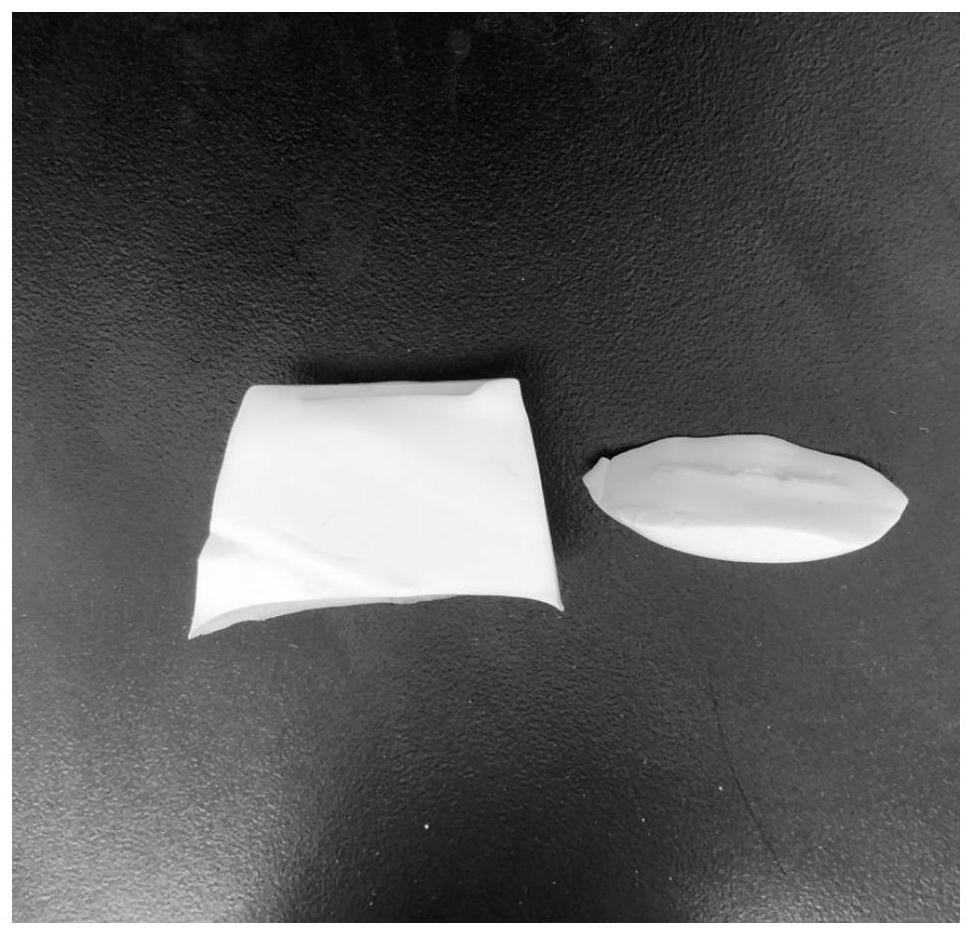

[0059] 4 Product state characteristics: After the product is dissolved, there is no obvious insoluble matter at the bottom, after gelation, it is milky white colloid, with smooth surface, smooth cut surface, elastic scoop, no obvious water separation after scooping, smooth Q-bomb at the entrance, There is obvious resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com