Grinding machine for metal parts

A technology of metal parts and grinding machines, which is applied in the direction of grinding racks, metal processing equipment, grinding machines, etc., can solve the problems of time-consuming, labor-intensive, high risk, and low risk of grinding, so as to keep clean, ensure healthy breathing, reduce possible effects of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

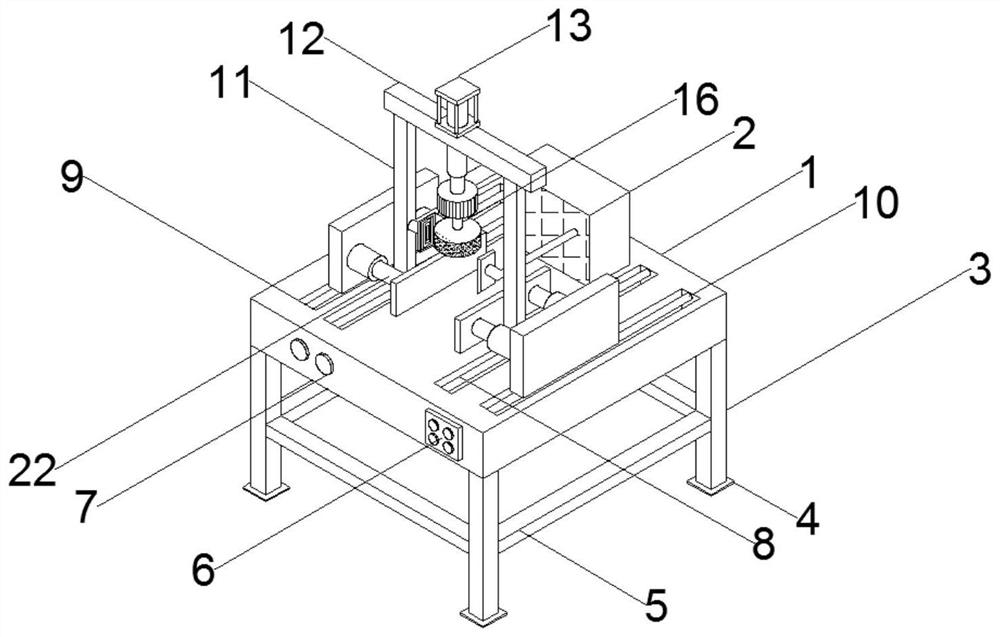

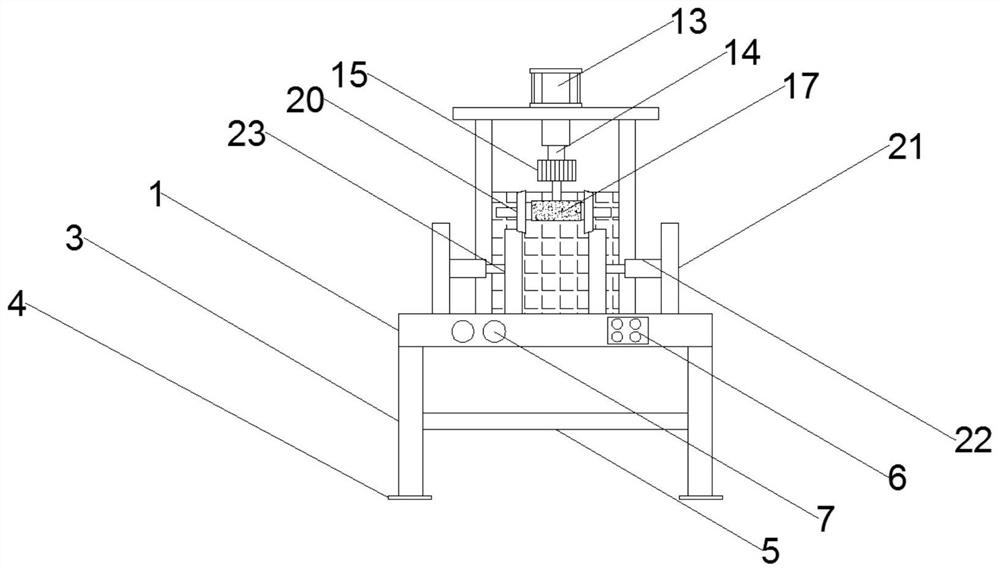

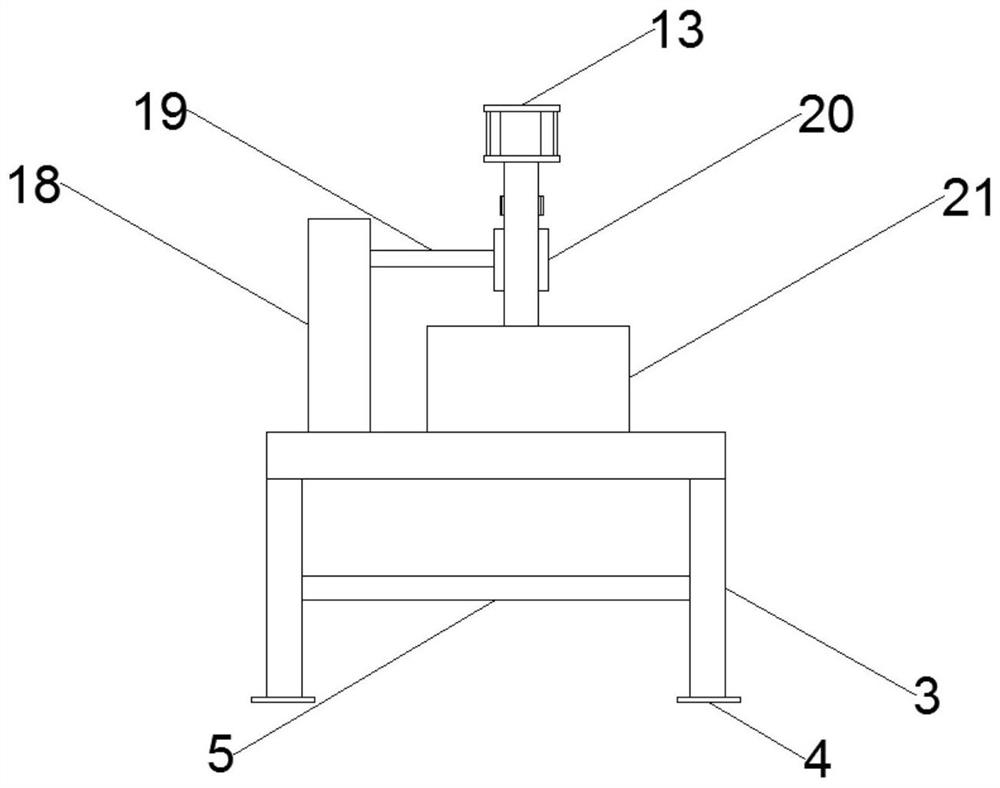

[0020] Example: such as Figure 1-3 As shown, a grinding machine for metal parts of the present invention includes a workbench 1 and a dust collection module 2, a bracket 3 is fixedly installed at the four corners of the bottom of the workbench 1, a gasket 4 is fixedly welded at the bottom of the bracket 3, and the middle part of the bracket 3 is fixedly installed There is a connecting frame 5, a control module 6 is provided on one side of the workbench 1, a mobile support switch 7 is provided on one side of the control module 6, a mobile support groove 8 and a telescopic fixed frame groove 9 are provided on the workbench 1, and the mobile support groove 8 and A spiral bar 10 is installed in the slot 9 of the telescopic fixed frame, and a movable bracket 11 is installed on one side of the slot 8 of the movable bracket. Hydraulic telescopic rod 14, the bottom of hydraulic telescopic rod 14 is fixedly equipped with grinding motor 15.

[0021] Among them, the bottom of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com