Reactive ultraviolet-proof finishing agent for textiles

An anti-ultraviolet, reactive technology, used in textiles and papermaking, fiber processing, light-resistant fibers, etc., can solve the problems of reduced protection effect and reduced anti-ultraviolet performance, and achieve improved water blocking and thermal insulation performance, and improved anti-ultraviolet Performance, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

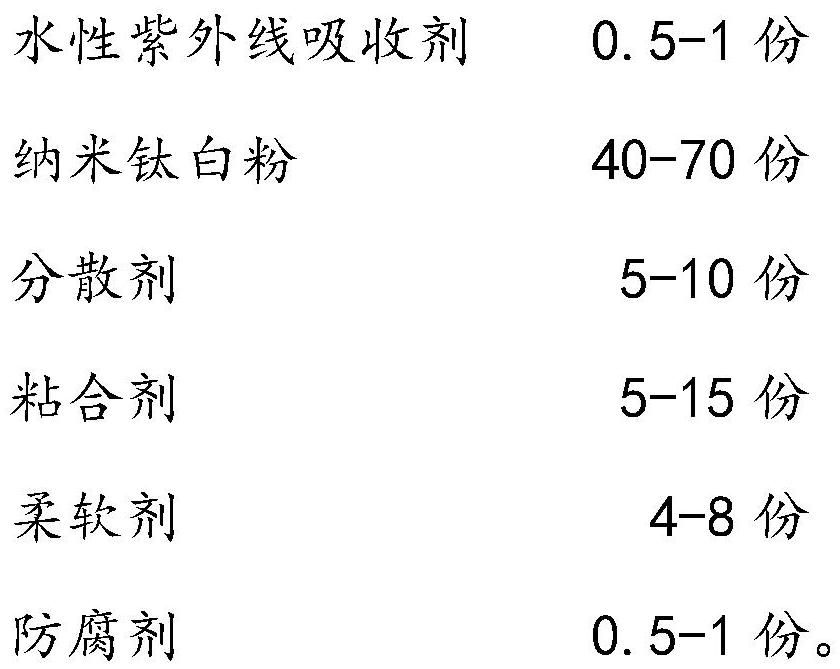

[0028] Embodiments of the present invention provide a reactive anti-ultraviolet finishing agent for textiles, which consists of the following specific components:

[0029]

[0030] The consumption of water-based ultraviolet absorber is controlled at 0.5-0.8% of the total weight.

[0031] Nano-titanium dioxide is hydrophilic nano-titanium dioxide, and the particle size of said nano-titanium dioxide is 15-50nm. Nano-titanium dioxide usually produces fine particles with significant changes in physical and chemical properties. The size of the fine particles is below 0.1 microns, and its appearance is White loose powder, with anti-ultraviolet, antibacterial, self-cleaning, anti-aging effects, and has a wide range of applications.

[0032] The preservative uses pentachlorophenol material.

[0033] A preparation method of a reactive anti-ultraviolet finishing agent for textiles, comprising the following specific steps:

[0034] S1. prepare a reactor, then add 60 parts of nano-ti...

Embodiment 2

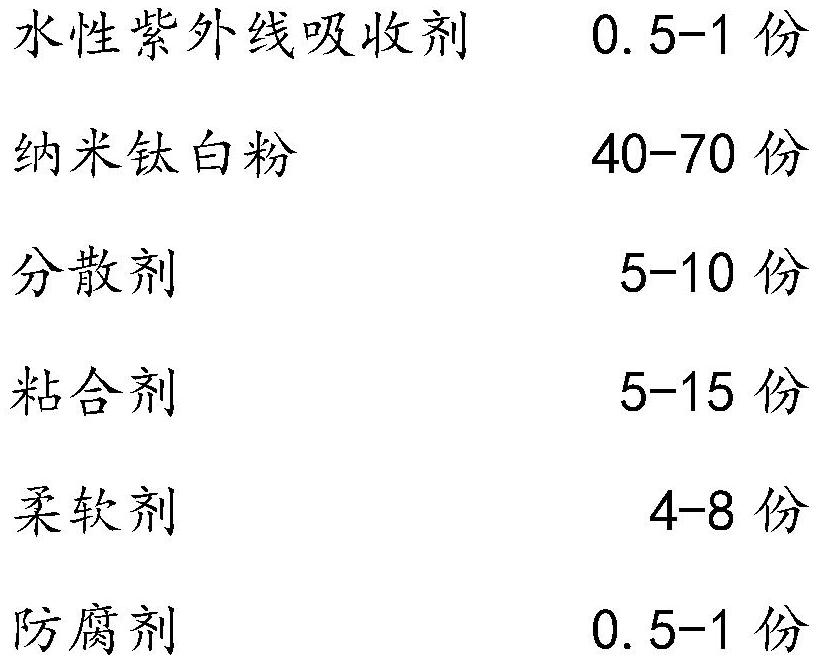

[0046] This embodiment is based on the basis of embodiment one: the configuration ratio of the reactive anti-ultraviolet finishing agent for this textile is adjusted to:

[0047]

[0048]

[0049] After configuring the reactive anti-ultraviolet finishing agent for textiles, the knitted fabric of the umbrella surface is treated with the anti-ultraviolet treatment agent, and the related equipment is used to detect the treated umbrella surface and the existing umbrella surface on the market. After finishing, the comparison results of the anti-ultraviolet protection performance of the umbrella surface and the existing umbrella surface are shown in the following table:

[0050]

Embodiment 3

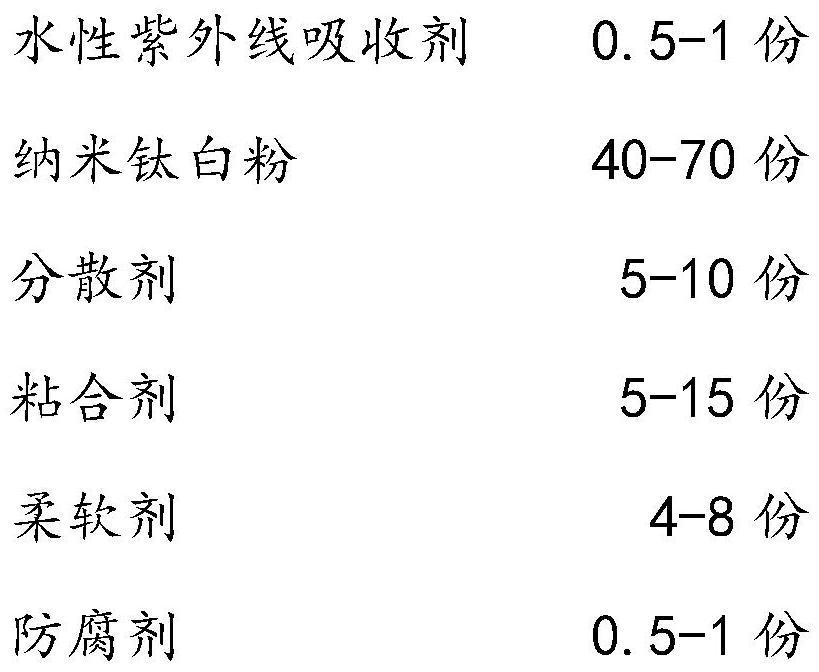

[0052] This embodiment is based on the basis of embodiment one: the configuration ratio of the reactive anti-ultraviolet finishing agent for this textile is adjusted to:

[0053]

[0054] After configuring the reactive anti-ultraviolet finishing agent for textiles, the knitted fabric of the umbrella surface is treated with the anti-ultraviolet treatment agent, and the related equipment is used to detect the treated umbrella surface and the existing umbrella surface on the market. After finishing, the comparison results of the anti-ultraviolet protection performance of the umbrella surface and the existing umbrella surface are shown in the following table:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com