High-dynamic imaging detection method and system for textile fabric flaws

A technology for textile fabrics and imaging detection, which is applied to the components of TV systems, optical testing for defects/defects, and image communication, etc. The cost of cloth inspection, the improvement of accuracy, and the effect of easy re-inspection and trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

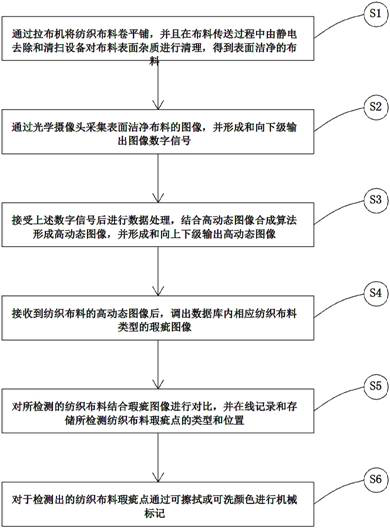

[0047] Example 1 please refer to figure 1 An embodiment shown is a high dynamic imaging detection method for textile fabric defects, including a mechanical pulling and cleaning module 1, an image acquisition module 2, a data processing and imaging module 3, a defect image database module 4, and an online Contrast and recording module 5, defect marking module 6 and control module 7, wherein: the central processing unit of the control module 7 controls and coordinates the remaining modules according to the following steps to complete high dynamic imaging, cloth defect point contrast detection and mechanical marking of defects;

[0048] S1. The mechanical stretching and cloth cleaning module 1: flatten the textile fabric roll through the stretching machine, and clean the impurities on the surface of the fabric by static electricity removal and cleaning equipment during the fabric transmission process, to obtain a clean surface fabric;

[0049] S2. The image acquisition module 2:...

Embodiment 2

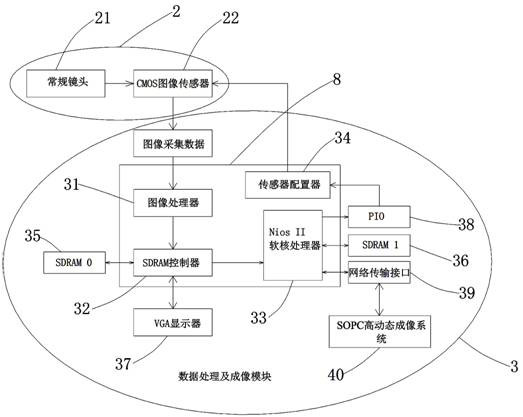

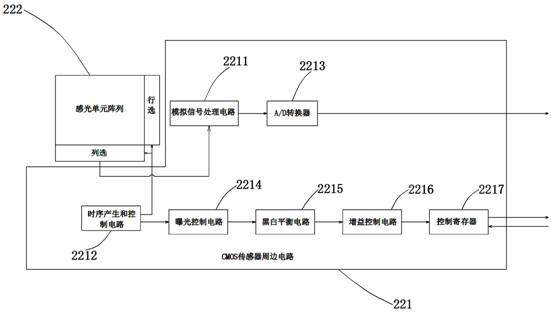

[0056] On the basis of the above-mentioned embodiment 1, please refer to the embodiment 2 figure 2 with image 3 An embodiment shown: the image acquisition module 2 is composed of a CMOS image sensor 22 and a conventional lens 21, an optical camera, and a magnesium light MT9N001 type COMS image sensor+ABF-F121212MP megapixel high-definition infrared monitoring lens for dynamic image formation The digital signal is sent to the data processing and imaging module 3 .

[0057] Described data processing and imaging module 3 are composed of image processor 31, SDRAM controller 32, Nios II soft-core processor 33, sensor configuration device 34, SDRAM-0 35, SDRAM-1 36, VGA display 37, PIO 38, network transmission interface 39 and SOPC high dynamic imaging system 40, wherein:

[0058] Described image processor 31, described SDRAM controller 32 and described sensor configurator 34 form FPGA control logic circuit 8, and in described FPGA control logic circuit 8, embed NiosII soft-core...

Embodiment 5

[0074] Example 5 please refer to Figure 4 A high dynamic imaging detection system for textile fabric defects is shown, including a mechanical pulling and cleaning module 1, an image acquisition module 2, a data processing and imaging module 3, a defect image database module 4, and an online comparison and recording module 5. The defect marking module 6 and the control module 7, wherein: the central processing unit of the control module 7 controls each module and coordinates the work of each module to complete high dynamic imaging, cloth defect point contrast detection and defect point mechanical marking;

[0075] The mechanical stretching and cloth cleaning module 1: flatten the roll of textile fabric through the stretching machine, and clean the impurities on the surface of the fabric by static electricity removal and cleaning equipment during the fabric transmission process, to obtain a clean surface cloth;

[0076] The image acquisition module 2: collect images of cloth wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com