Process industrial equipment inspection data processing method, inspection system, device and storage medium

An industrial equipment and data processing technology, which is applied in the direction of measuring devices, radio wave measuring systems, inspection time patrols, etc., can solve the problems of two-dimensional codes being easily stained, falling off, and high maintenance costs, and achieve reduced construction costs and high positioning accuracy , Improve the effect of recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

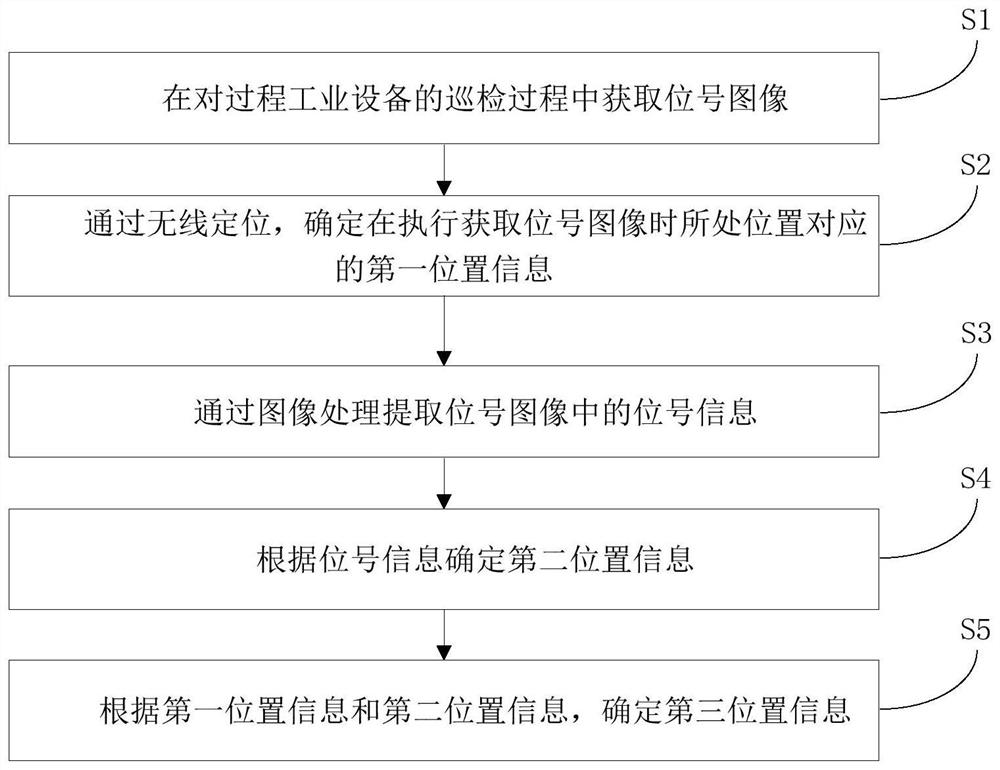

[0040] In this embodiment, a process industry equipment inspection data processing method is provided, referring to figure 1 , the process industry equipment inspection data processing method includes the following steps:

[0041] S1. Obtain a tag image during the inspection process of the process industrial equipment; the tag image includes the tag information of the process industrial equipment;

[0042] S2. Through wireless positioning, determine the first location information corresponding to the location when performing the acquisition of the tag image;

[0043] S3. Extracting the tag information in the tag image through image processing;

[0044] S4. Determine the second position information according to the bit number information;

[0045] S5. Determine third location information according to the first location information and the second location information; the third location information is used to represent the location of the process industrial equipment.

[0046...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap