Semiconductor structure and forming method thereof

A technology of semiconductors and structural materials, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that semiconductor chips cannot achieve the etching effect, cannot meet the integration density of semiconductor chips, and reduce the yield of semiconductor devices. The effect of good etching effect, less defects and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background, there is a need to improve the pattern accuracy of current self-aligned multiple imaging techniques.

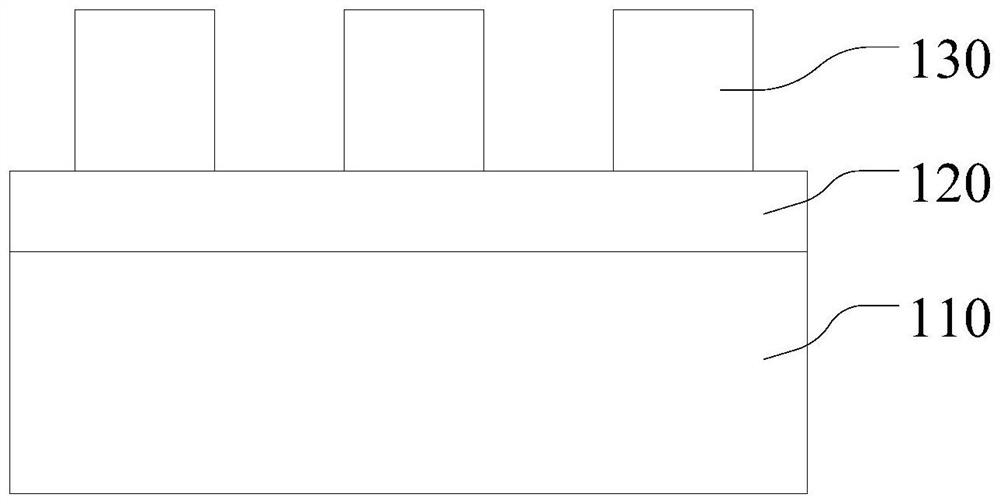

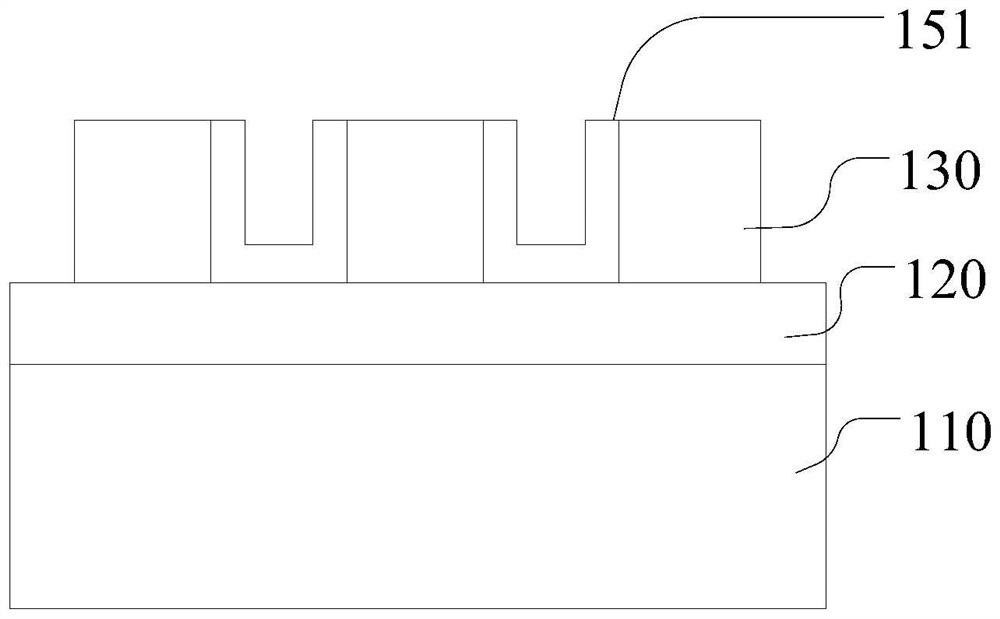

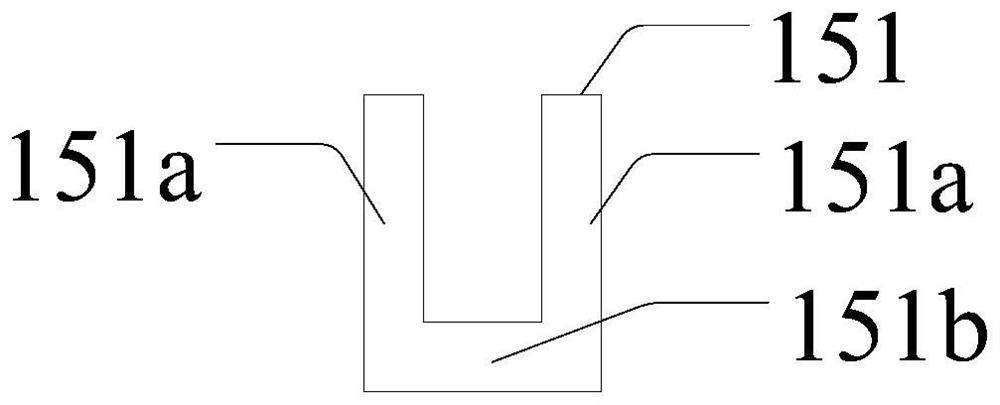

[0035] Figure 1 to Figure 5 It is a schematic diagram of the cross-sectional structure of the pattern formation process of a self-aligned multiple pattern technology.

[0036] Please refer to figure 1 A liner layer 120 is provided on the layer to be etched 110, a sacrificial material layer (not shown) is formed on the surface of the liner layer 120, and the sacrificial material layer is etched to form several discrete sacrificial layers 130;

[0037] Please refer to figure 2 , depositing a mask material layer (not shown) on the surface of the liner layer 120 and the surface of the sacrificial layer 130, etching the mask material layer to form a mask structure 151, here figure 2 Two mask structures 151 are schematically drawn;

[0038] Please refer to image 3 , the mask structure 151 includes a first portion 151a and a second por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com