Osmanthus fragrans black tea making process

A production process and technology of sweet-scented osmanthus, which is applied in the directions of tea, tea spice, tea treatment before extraction, etc., can solve the problems of low aroma loss rate, quality needs to be improved, etc., so as to increase the release amount, improve the quality of finished products and preparation efficiency, and achieve long-lasting aroma. rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

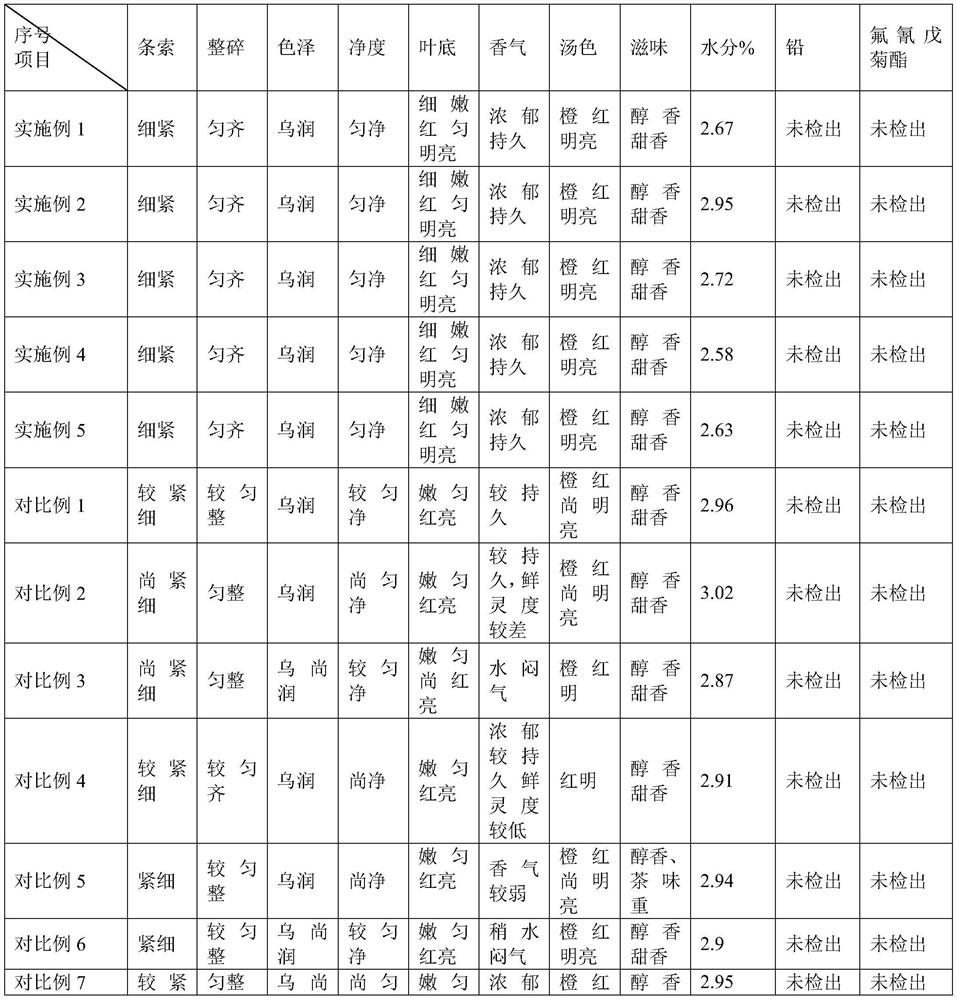

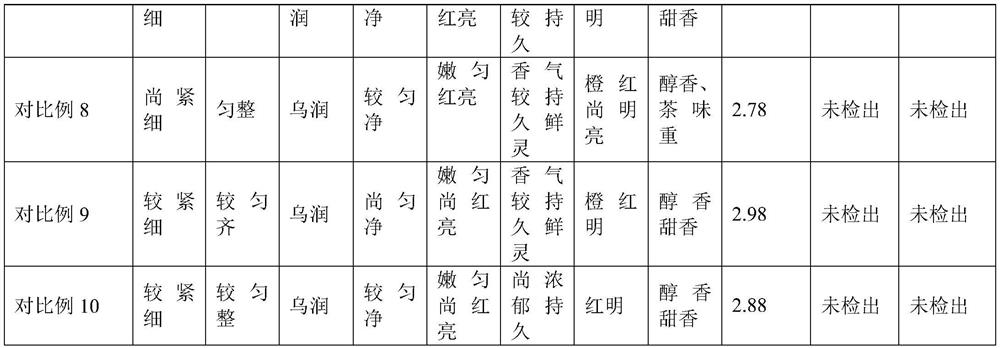

Examples

Embodiment 1

[0051] A kind of Osmanthus fragrans black tea preparation technology, comprises following preparation steps:

[0052] (1) Selection of tea base and sweet-scented osmanthus

[0053] Select the refined Qihong Maofeng as the tea base; choose the osmanthus or silver osmanthus varieties. The picking conditions for the osmanthus are before ten o'clock in the morning on a sunny day, the temperature is 28°C, and the osmanthus with an opening rate of 72% is picked. Pick them and put them in a cool place.

[0054] (2) pretreatment of tea base;

[0055] The pre-treatment of the tea dregs is as follows: the selected tea dregs are refired at 100°C, and the water content of the tea dregs is 4% after refire, and then cooled in time, packed into bags after cooling, and placed in the scenting workshop for standby.

[0056] (3) pretreatment of osmanthus

[0057] The specific process of pre-treatment of osmanthus: After picking osmanthus, cymes cluster in the leaf axils, cut off the 0.5cm bra...

Embodiment 2

[0065] A kind of Osmanthus fragrans black tea preparation technology, comprises following preparation steps:

[0066] (1) Selection of tea base and sweet-scented osmanthus

[0067] Select the refined Qihong Maofeng as the tea base; choose the osmanthus or silver osmanthus varieties. The picking conditions for the osmanthus are before ten o'clock in the morning on a sunny day, the temperature is 27°C, and the osmanthus with an opening rate of 70% is picked. Pick them and put them in a cool place.

[0068] (2) pretreatment of tea base;

[0069] The pre-treatment of the tea dregs is as follows: the selected tea dregs are refired at 95°C, and the water content of the tea dregs is 3.5% after refire, and then cooled in time, packed into bags after cooling, and placed in the scenting workshop for standby.

[0070] (3) pretreatment of osmanthus

[0071] The specific process of pre-treatment of sweet-scented osmanthus: after picking sweet-scented osmanthus, cymes are clustered in le...

Embodiment 3

[0079] A kind of Osmanthus fragrans black tea preparation technology, comprises following preparation steps:

[0080] (1) Selection of tea base and sweet-scented osmanthus

[0081] Choose the refined Qihong Maofeng as the tea base; choose the osmanthus or silver osmanthus varieties. The picking conditions for the osmanthus are before ten o'clock in the morning on a sunny day, the temperature is 30 ℃, and the osmanthus with an opening rate of 75% is picked. Pick them and put them in a cool place.

[0082] (2) pretreatment of tea base;

[0083]The pre-treatment of the tea dregs is as follows: the selected tea dregs are refired at 95°C, and the water content of the tea dregs is 3.5% after refire, and then cooled in time, packed into bags after cooling, and placed in the scenting workshop for standby.

[0084] (3) pretreatment of osmanthus

[0085] The specific process of pre-treatment of sweet-scented osmanthus: After picking sweet-scented osmanthus, cymes are clustered in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com