Automatic control method for boiler flue gas baffle of ultra-supercritical generator set

A technology for boiler flue gas and generator sets, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of catalyst wear, excessive denitration emissions, catalyst side reactions, etc. Hot steam temperature, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

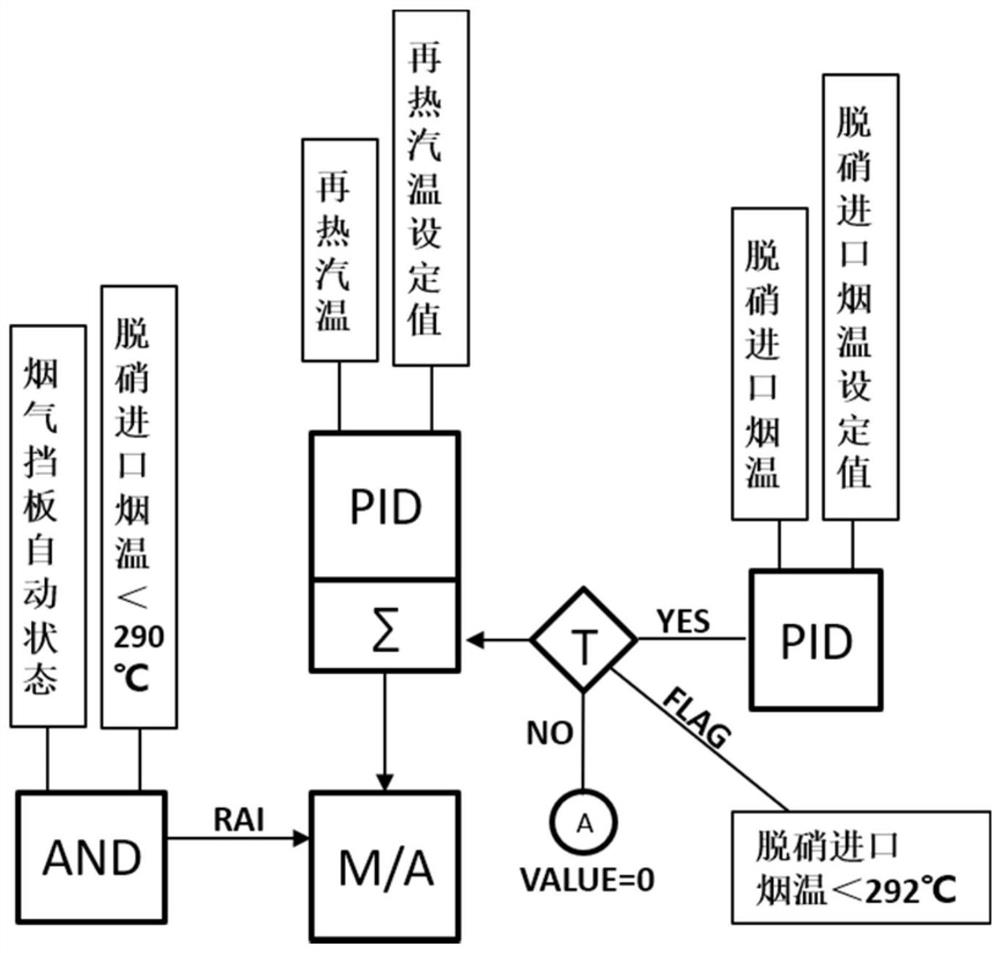

Method used

Image

Examples

Embodiment

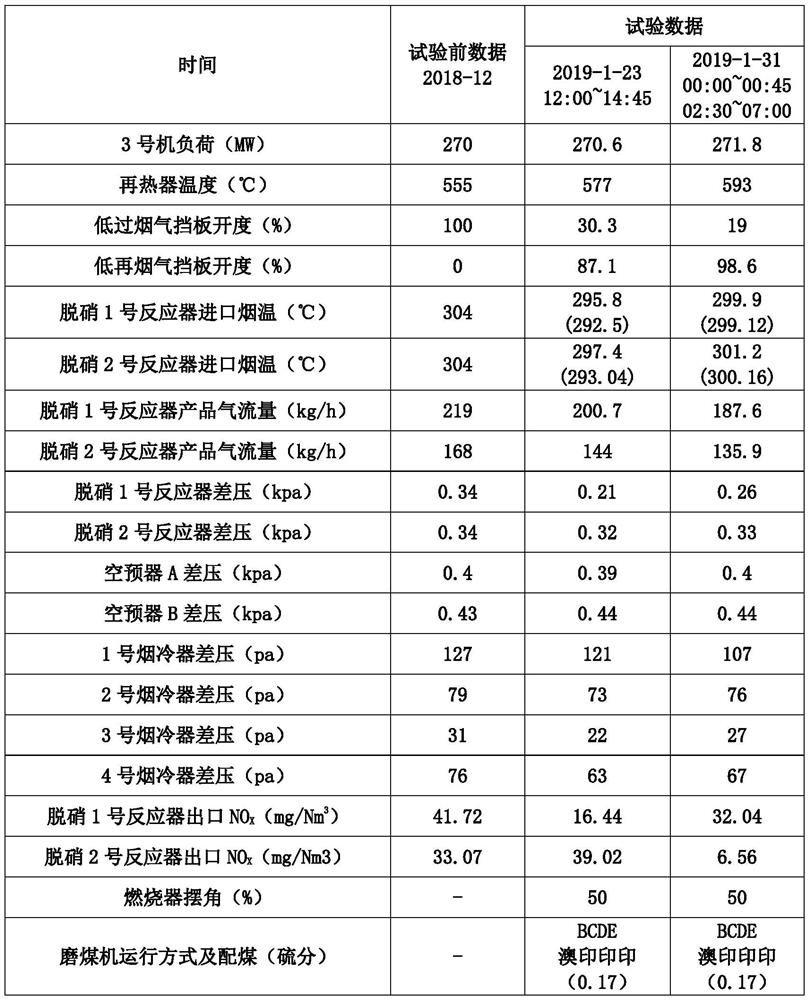

[0027] Huaneng Shanghai Shidongkou No. According to the various parameters of the boiler during low-load operation under the means, it can be seen that the average reheat steam temperature is only 555°C under the condition of satisfying the normal operation of denitrification.

[0028] time 2018-12 Unit 3 load (MW) 270 Reheat steam temperature (℃) 555 Lower smoke baffle opening (%) 100 Low re-smoke gas baffle opening (%) 0 Inlet flue temperature of denitrification No. 1 reactor (°C) 304 Inlet flue temperature of No. 2 denitrification reactor (°C) 304 Product gas flow rate of No. 1 denitrification reactor (kg / h) 219 Product gas flow rate of No. 2 denitrification reactor (kg / h) 168 Differential pressure of No. 1 denitrification reactor (kpa) 0.34 Differential pressure of No. 2 denitrification reactor (kpa) 0.34 Air preheater A differential pressure (kpa) 0.4 Air preheater B differential pressure (kpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com