A pipeline inner wall spraying robot and spraying method

A technology for spraying robots and pipes, applied in coatings, spray booths, spraying devices, etc., can solve the problems of polluting the environment and people's physical and mental health, spraying materials easily falling on robots, and reducing rust prevention ability, etc., to reduce economic losses, Improve the quality of spraying and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0040] According to an embodiment of the present invention, a pipeline inner wall spraying robot and a spraying method are provided.

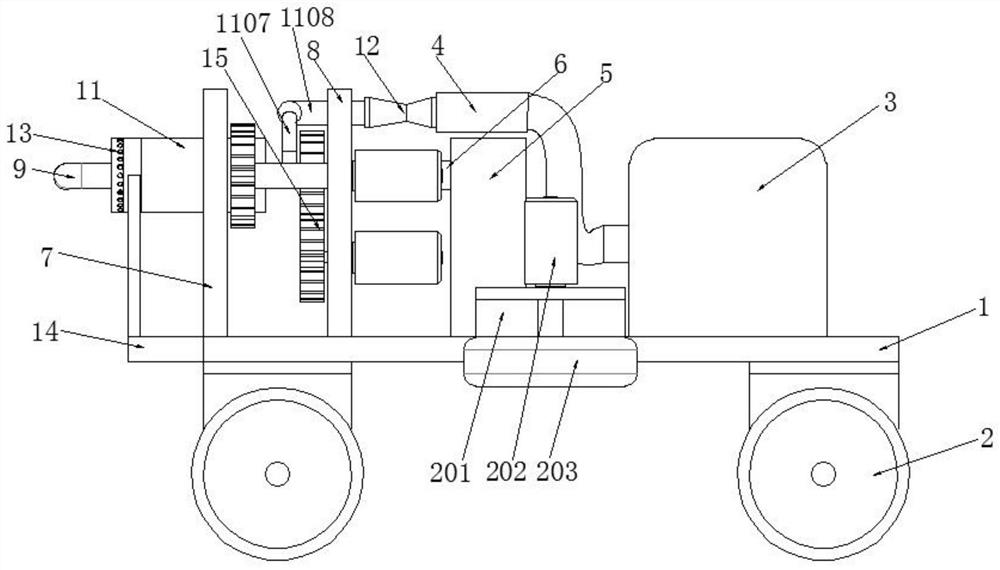

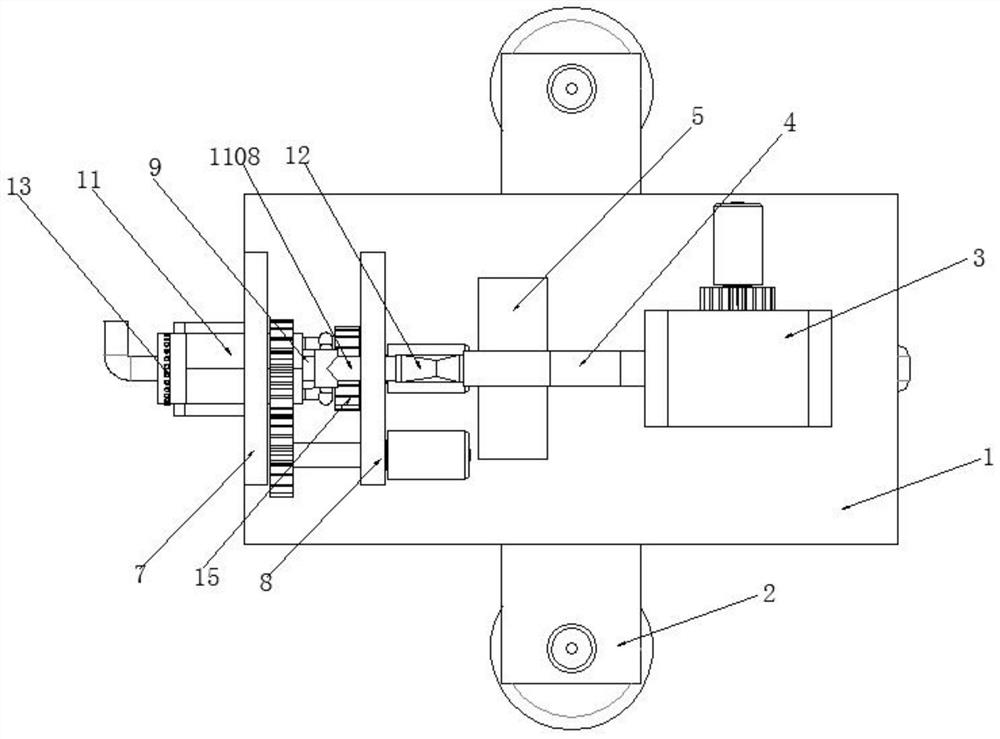

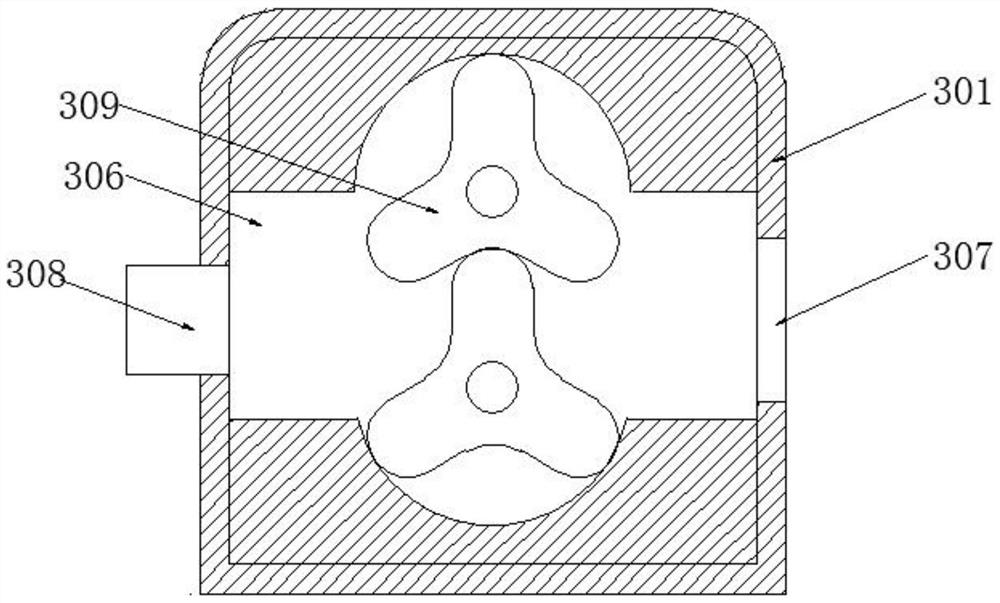

[0041] Such as Figure 1-10 As shown, the pipeline inner wall spraying robot according to the embodiment of the present invention includes a support plate 1, two sets of walking mechanisms 2 are respectively arranged on the bottom end of the support plate 1 and both sides of the support plate 1, and one end of the top of the support plate 1 is provided with There is an air supply mechanism 3, the left end of the air supply mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com