Visual inspection and obstacle avoidance system for industrial robot

An industrial robot and visual inspection technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as inability to record and trace back the running state of industrial robots, low processing speed requirements for visual inspection algorithms, and low operating efficiency of industrial robots. , to achieve the effect of rapid convergence, reasonable obstacle avoidance path planning, and avoidance of obstacle avoidance failure accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

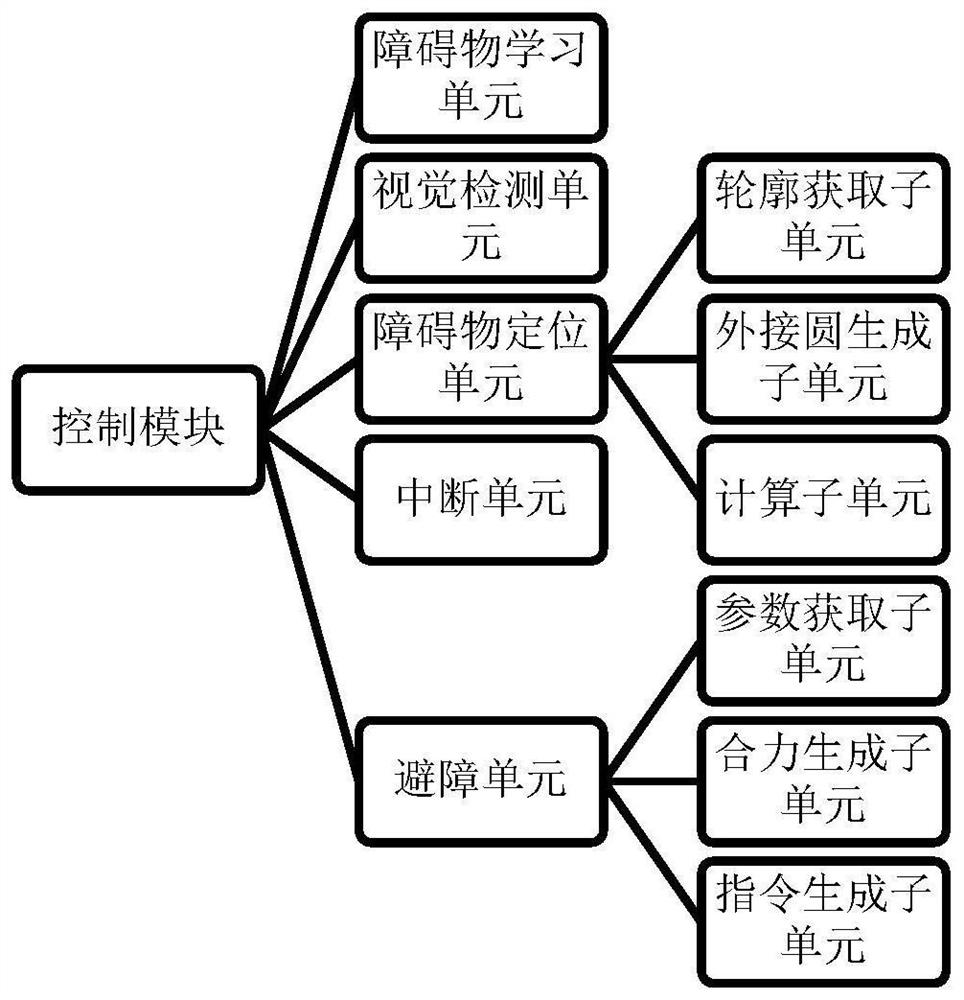

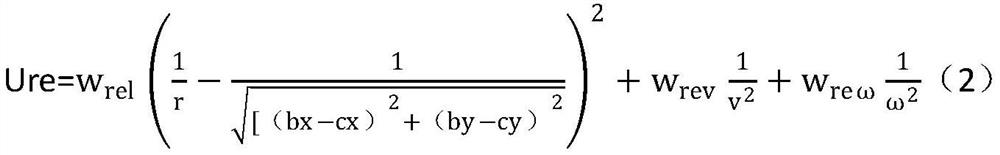

[0027] An industrial robot visual detection and obstacle avoidance system, including an industrial robot body, a camera module, a control module, a block chain module, and a wheel train module. The camera module includes a binocular camera set at the front end of the robot body for collecting real-time image, and transmit the real-time image to the control module; the control module is set inside the industrial robot body, and is used to receive the target point sequence in the target instruction sent by the user terminal, and establish a travel task list; for the binocular camera The collected real-time images are received, and the obstacles in front are initially identified through the classification algorithm, and the coordinates and sizes of the obstacles are further determined, the current traveling task is interrupted, and the obstacle avoidance task is performed. According to the current operating status of the industrial robot, the obstacle Coordinates and size and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com