Polymer composite paperboard and preparation method thereof

A composite cardboard and polymer technology, applied in the field of cardboard, can solve problems such as poor stability and reliability, complex calender structure, complex production process, etc., to ensure quality, stable and reliable calendering effect, and tear resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

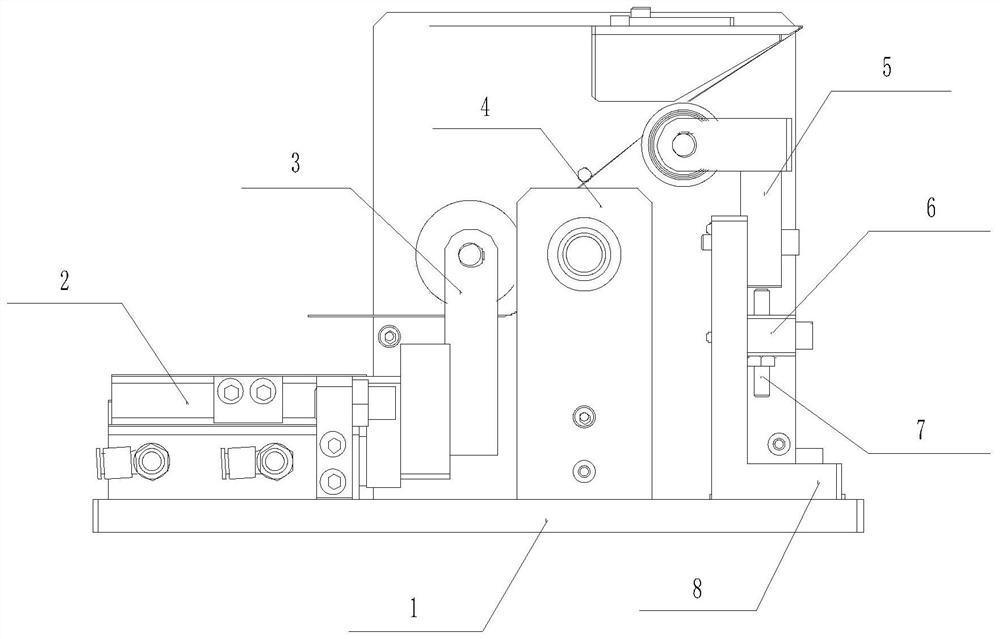

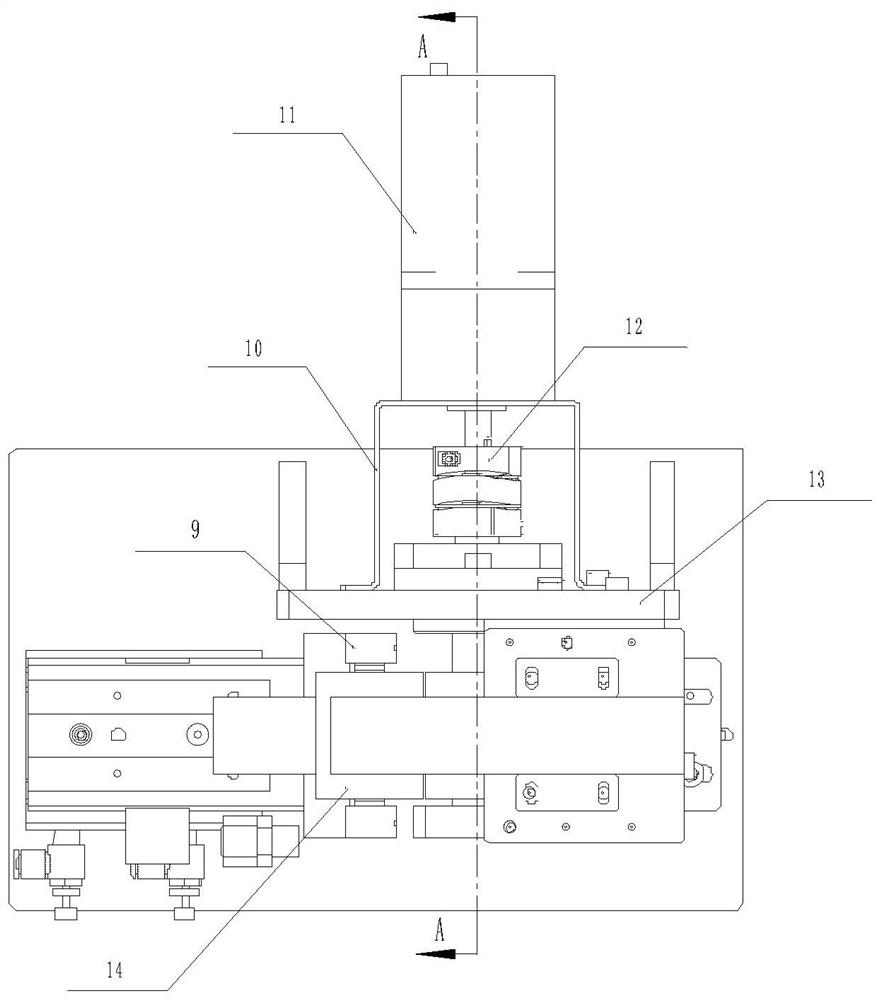

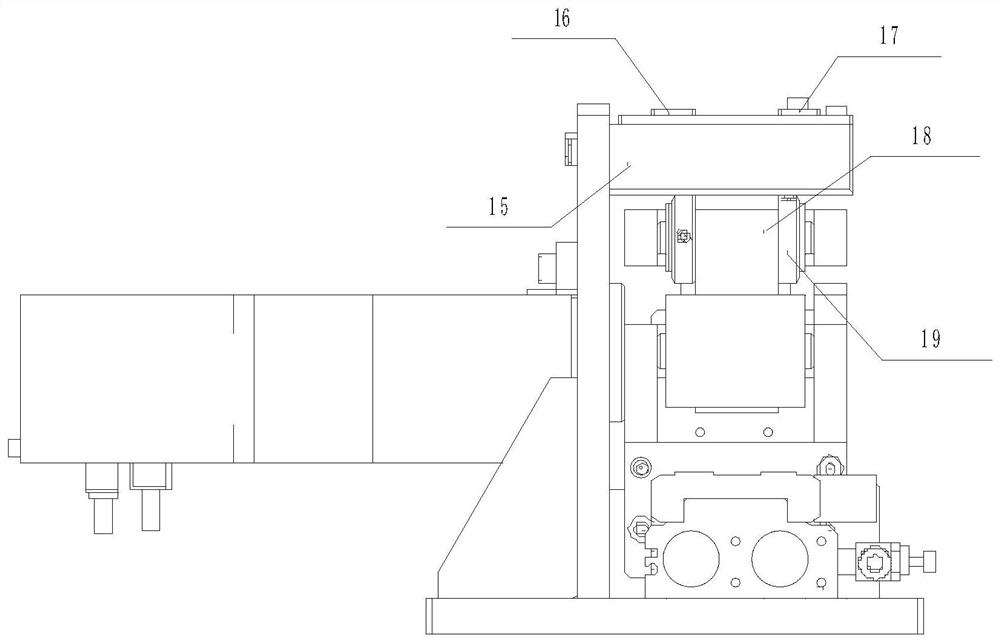

[0020] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0021] A polymer composite cardboard, comprising the following raw materials in parts by weight: 80-120 parts of low-density polyvinyl chloride, 30-50 parts of polypropylene, 120-160 parts of calcium carbonate, 10-20 parts of polyethylene wax, 15-20 parts of 25 parts of boric acid ester coupling agent, 4-8 parts of heavy calcium carbonate, 4-8 parts of light calcium carbonate and 10-18 parts of color masterbatch.

[0022] Preferably, the production equipment in the preparation method is a calender, and the calender is composed of a base 1, a slide cylinder 2, a front bracket 3, a front bearing seat 4, an adjustment seat 5, a fixed block 6, an adjustment screw 7. Mounting support 8, rear bracket 9, motor mounting base 10, drive motor 11, coupling 12, bracket 13, driven pressure roller 14, support seat 15, rear limit block 16, front limit block 17, Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com