Metal-air fuel battery stack with easily-replaced open anode

A fuel cell stack and metal-air technology, applied to battery pack parts, fuel cell half-cells, secondary battery half-cells, secondary batteries, etc., can solve the problems of metal waste and cumbersome procedures, and achieve Simplified maintenance, thorough cooling, and improved inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

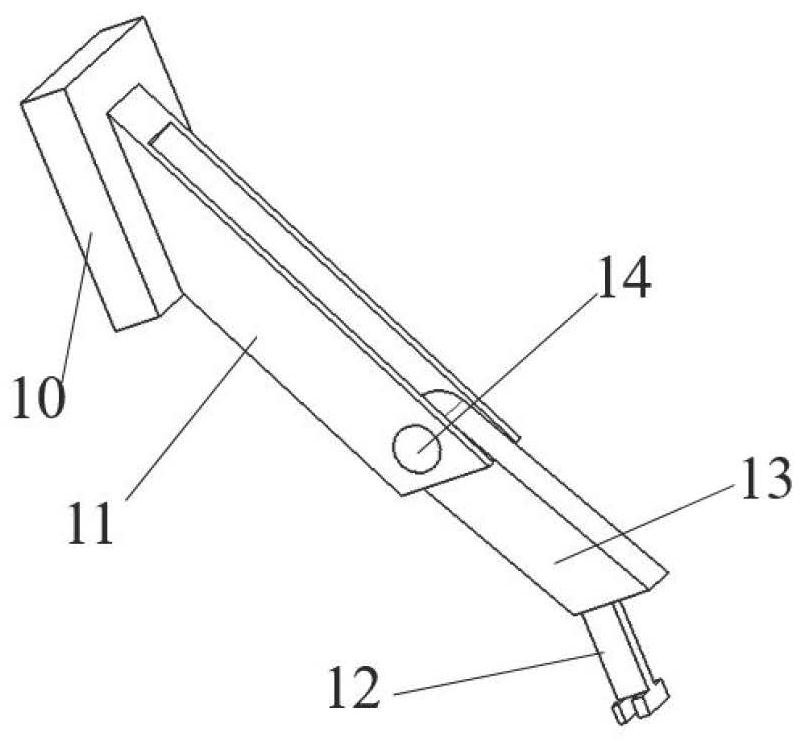

[0039] The metal-air fuel cell stack with an open anode easily replaceable in this embodiment includes: an electrolyte pool, an anode circulation device, a lifting bump, an anode connecting rod, an air electrode and a metal electrode.

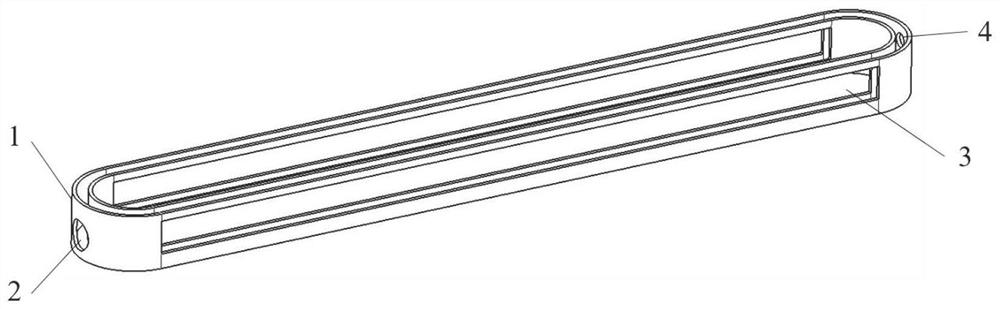

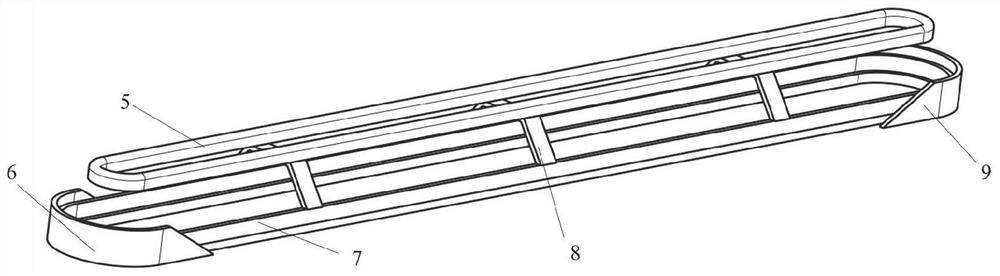

[0040] figure 1 It is a schematic structural diagram of the electrolyte cell in Example 1 of the present invention. Such as figure 1 As shown, the electrolyte pool 1 in this embodiment is an annular electrolyte pool, the electrolyte pool 1 is filled with electrolyte, and all metal electrodes are vertically immersed in the electrolyte. An electrode tank 3 is provided on the side wall of the electrolyte pool 1, the air electrode is fixed in the electrode tank 3, the ion side of the air electrode is immersed in the electrolyte, and the air side of the air electrode is exposed to the electrolyte pool. 1 outside air. The electrode slot 3 is square in the figure. A large-area integrated air electrode can be installed in the electrode slot 3, whic...

Embodiment 2

[0050] In this embodiment, on the basis of Embodiment 1, a circulation system is added. Figure 5 It is a structural schematic diagram of Embodiment 2 of the present invention. Such as Figure 5 As shown, the circulation system in this embodiment includes a temperature sensor 22 , an electronic control unit 24 , a sedimentation tank 18 , a filter screen 17 , a circulation pump 16 and a radiator 15 . The outlet 2 of the electrolyte pool is connected to the first inlet of the sedimentation tank 18 by a pipeline, and the filter screen 17 is fixed at the outlet position in the sedimentation tank 18; the outlet of the sedimentation tank 18 passes through The pipeline is connected to the inlet of the circulation pump 16, the outlet of the circulation pump 16 is connected to the inlet of the radiator 15 through the pipeline, and the outlet of the radiator 15 is connected to the electrolyte pool through the pipeline. Liquid inlet 4. The temperature sensor 22 is fixed in the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com