Large-feeding-amount multi-reel-disc type sorghum ear header and sorghum harvester

A technology with large feeding amount and spike head, applied in the direction of harvester, header, cutter, etc., can solve the problems of increasing power consumption and mechanical load, large mechanism height, loss of machine life, etc., and improve work stability. The effect of reducing the moment of inertia, reducing the moment of inertia, and increasing the contact stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

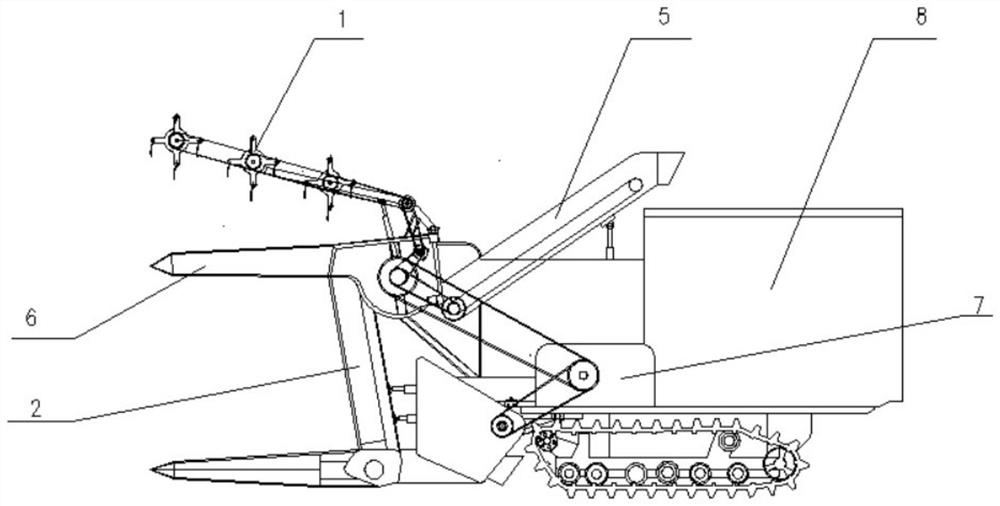

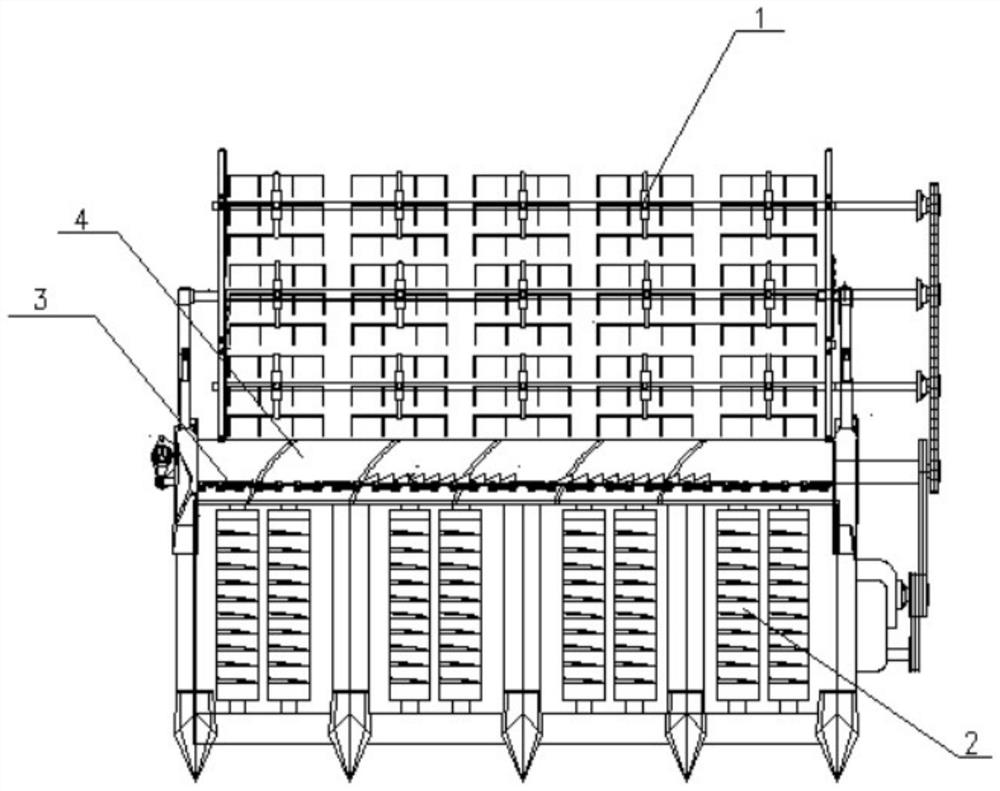

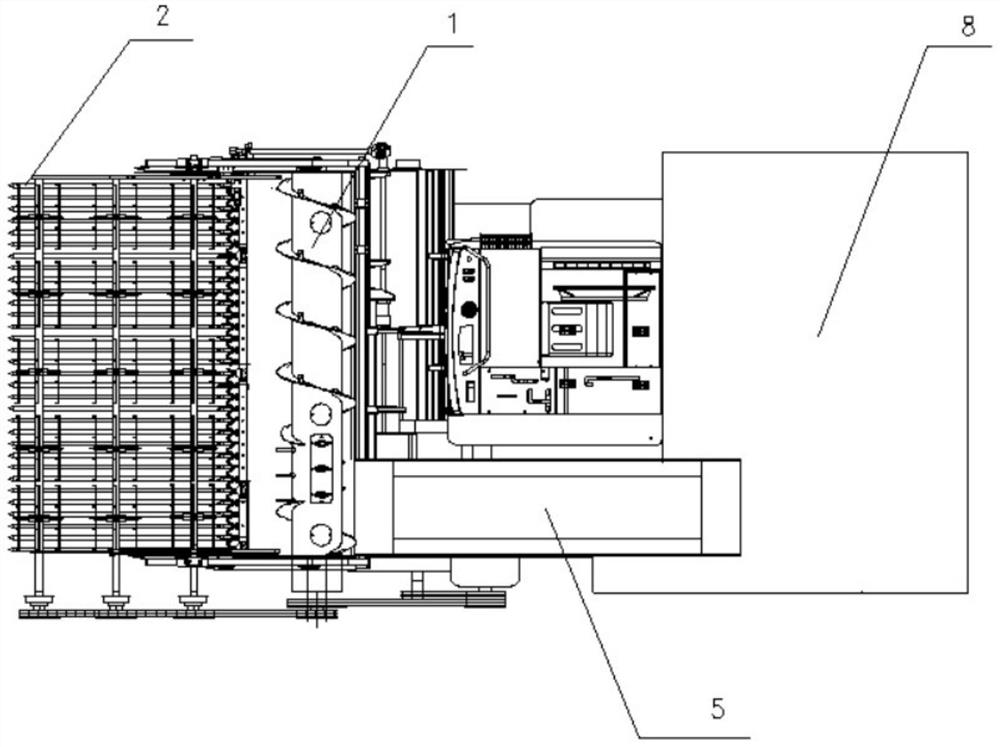

[0041]Such asfigure 1 ,figure 2 withimage 3 As shown, the sorghum harvester of the present invention includes a sorghum head cutting platform, a feeding auger 4, a head conveyor 5, a straw support 6, an engine 7, a grain box 8 and a frame; the sorghum head The head cutting table includes an ear pulling table 1, a bar crushing device 2 and a reciprocating cutter device 3. The reciprocating cutting knife device 3 is used to cut the ears from the ear pulling table 1, and the bar breaking device 2 is located Below the ear platform 1 is used to chop up the remaining sorghum stalks; one end of the sorghum ear cutting platform is mounted on a rotating auxiliary mounting frame, and the straw support 6 is installed on the ear setting platform 1 located on the sorghum ear cutting platform On the lower fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com