Composite sealing ball valve

A composite ball valve technology, applied in the shaft seal, valve details, valve device, etc., can solve the problems of long time consumption, gas waste, high maintenance cost, etc., and achieve the effect of convenient and quick replacement, low production cost and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

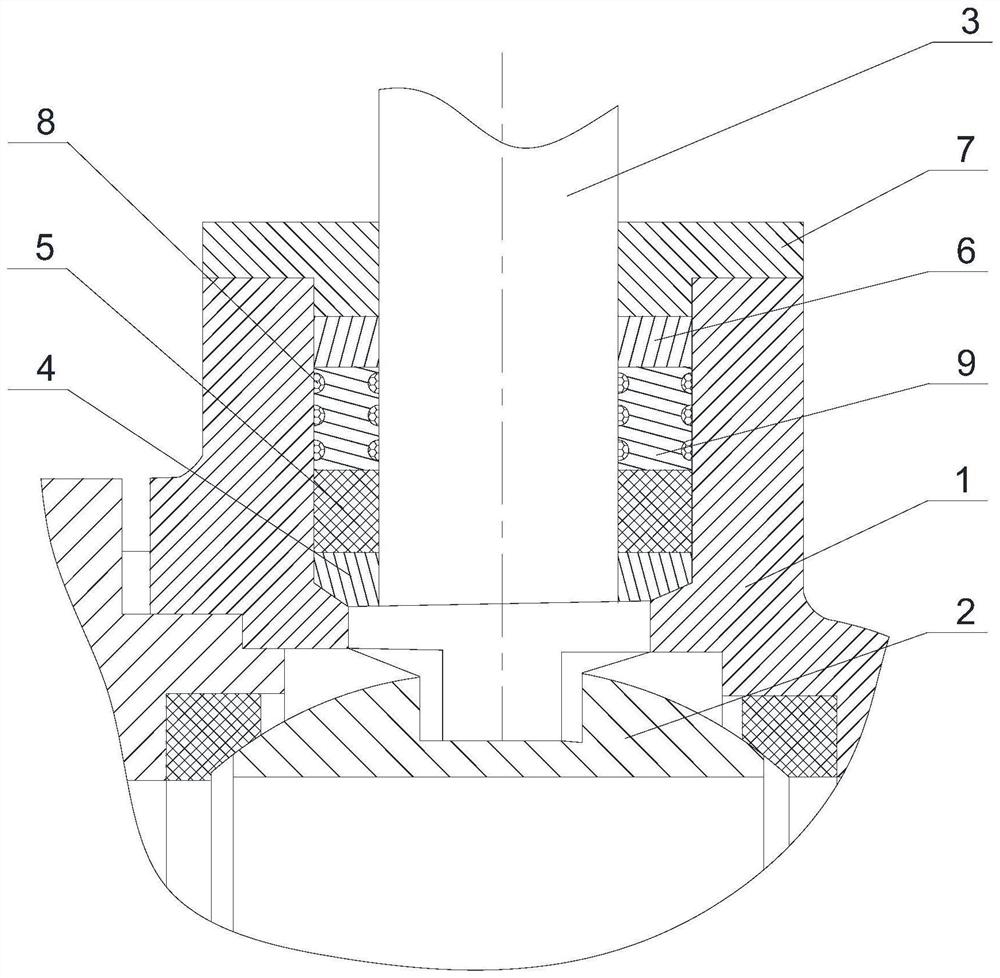

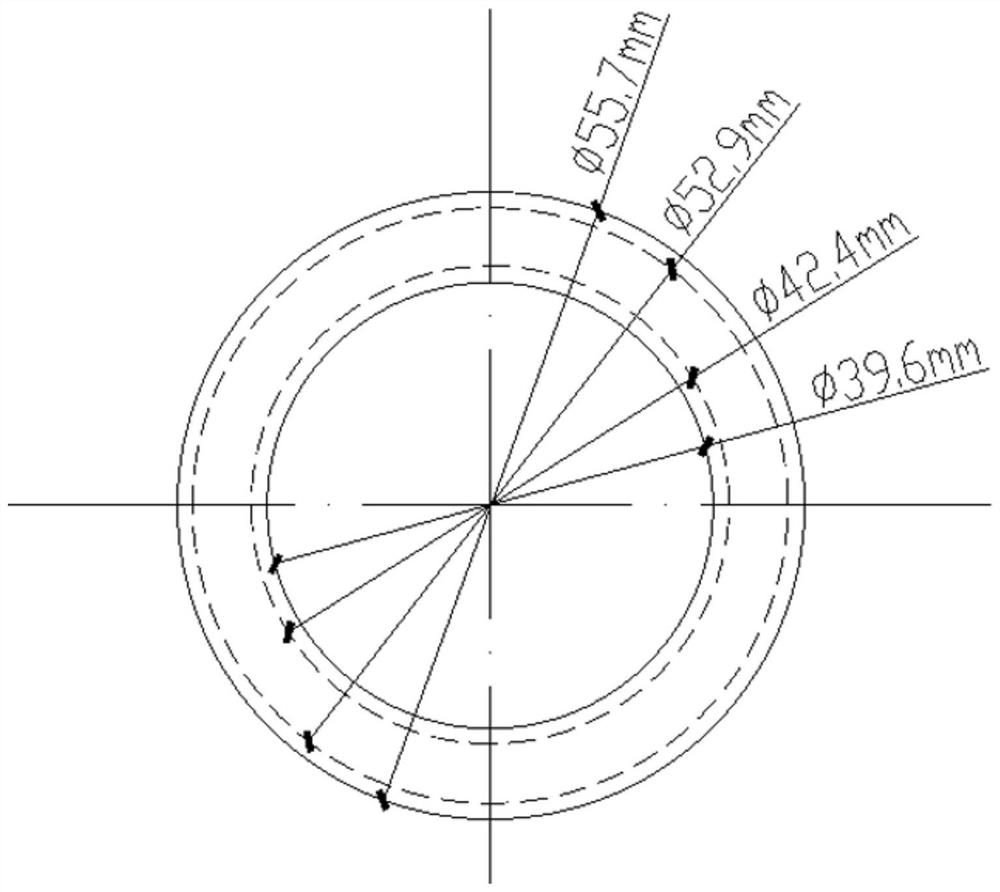

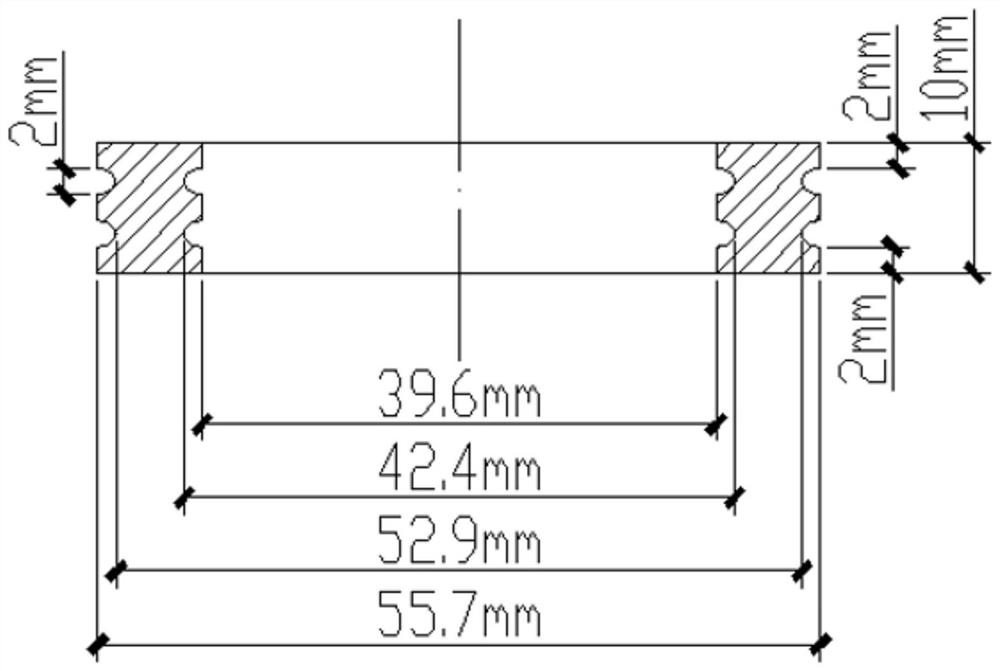

[0013] Embodiment 1: A compound sealed ball valve, which includes a ball valve seat 1, a valve core 2 is arranged inside the ball valve seat 1, one end of the valve stem 3 is fixedly connected with the valve core 2, and the other end of the valve stem 3 faces outward Extending through the valve seat of the ball valve and fixedly connected with the driving mechanism, the driving mechanism can be a wrench or an electric actuator; a sealing cavity is provided between the valve seat 1 of the ball valve with the valve stem 3 and the valve stem 3, and the sealing cavity is formed by A packing pad 4, a polytetrafluoroethylene packing layer 5, and a compression sleeve 6 are set sequentially from the inside to the outside, and a ball valve gland 7 is connected to the port of the sealing cavity, and the inner end surface of the ball valve gland 7 is in contact with the compression sleeve 6; There is also an O-ring sealing support ring assembly between the PTFE packing layer 5 and the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com