Adhesive composition

A composition and adhesive technology, applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve the problems of short open time, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0085] The following examples are given to further illustrate the invention, but are not to be construed as limiting the scope of the claims. All parts and percentages are by weight unless otherwise indicated.

[0086] The various raw materials used in the examples are explained below:

[0087] Desmodur N3400, available from Covestro, is an aliphatic polyisocyanate based on hexamethylene diisocyanate.

[0088] Isonate M143 is a liquefied MDI with a functionality of 2.2 and a viscosity of 40 mPa-s. Isonate M143 is available from The Dow Chemical Company (Dow).

[0089] Isonate M342 is a polymeric MDI with a functionality of 2 and a viscosity of 580 mPa-s, available from Dow.

[0090] VORANATE M220 is a polymeric MDI having a functionality of 2.7 and a viscosity of 205 mPa-s, available from Dow.

[0091] Metatin T713 is a tin-based dibutyltinmercaptide catalyst; and available from ACIMA Corporation.

[0092] Di-n-octylbis[isooctylthioglycolate]tin, a tin-based dioctyltinmer...

example 1-8 and comparative example A-D

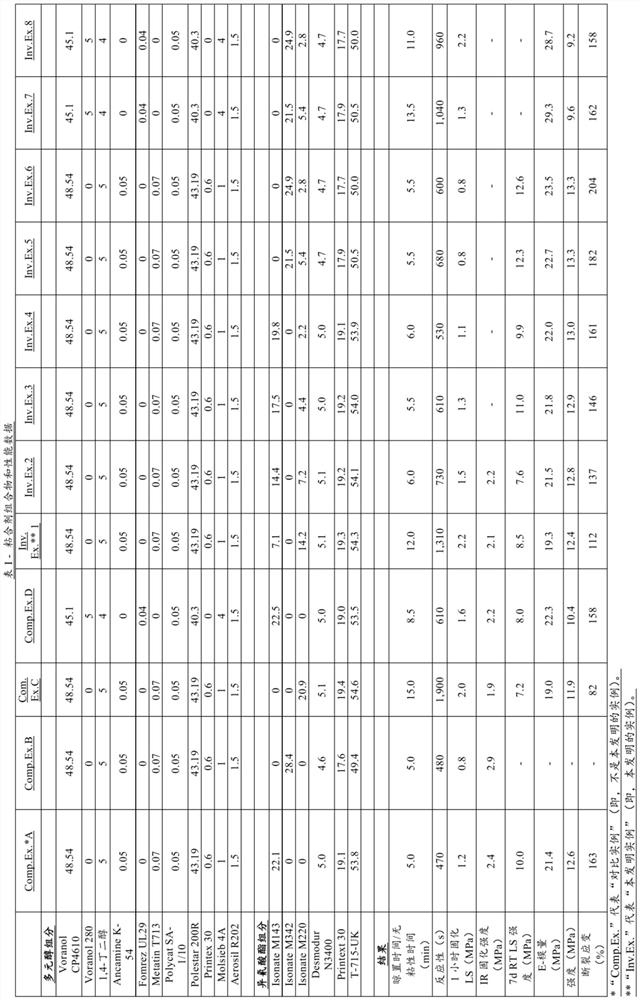

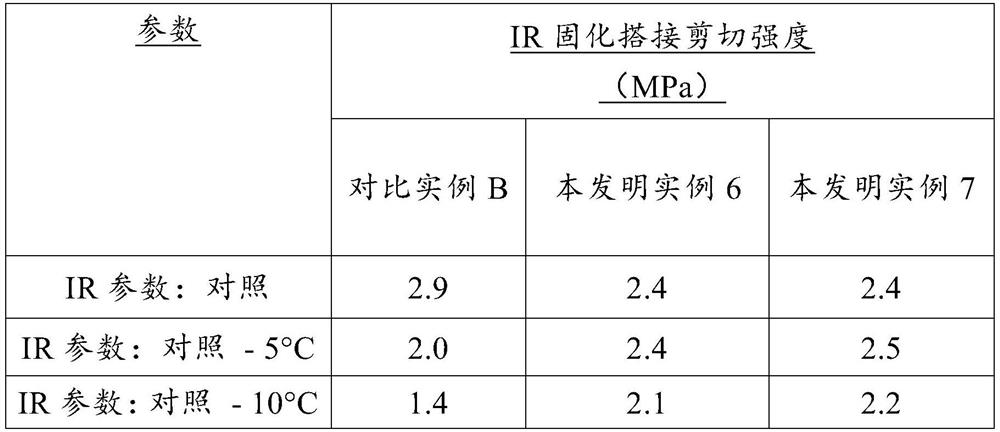

[0122] Table I below describes the formulations of Comparative Examples A-D and Inventive Examples 1-8; and the results of the performance data after testing the adhesive compositions. The open times of the adhesive compositions of Comparative Examples A-D and Examples 1-8 were measured by the rheological reactivity test described above. Lap shear strength was measured with e-coated steel substrates at 1 h and 7d RT. Lap shear ("1h-lap shear") strength was measured with e-coated steel substrates having bond dimensions of 15 mm x 25 mm x 1.5 mm. Tensile testing was performed on Dogbones 5A test samples as described above. Table I depicts the results of tests performed on Dogbones 5A samples using various adhesives. Lap shear IR thermal cure experiments were run with a heating cycle of 180 s and with CFK substrates (available from Dow) with bond dimensions of 45 mm x 15 mm x 1.5 mm. At a sample thickness of

[0123] Tensile properties were measured at 2 mm.

[0124] It was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lap shear strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com