Large-caliber duplex stainless steel butt shielded welding device

A duplex stainless steel, shielded welding technology, applied in welding protection devices, welding equipment, welding accessories, etc., can solve the problems of high welding requirements of washing towers, inability to meet the design and use requirements of welding seams, etc. rate and weld quality, good promotion and application value, economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

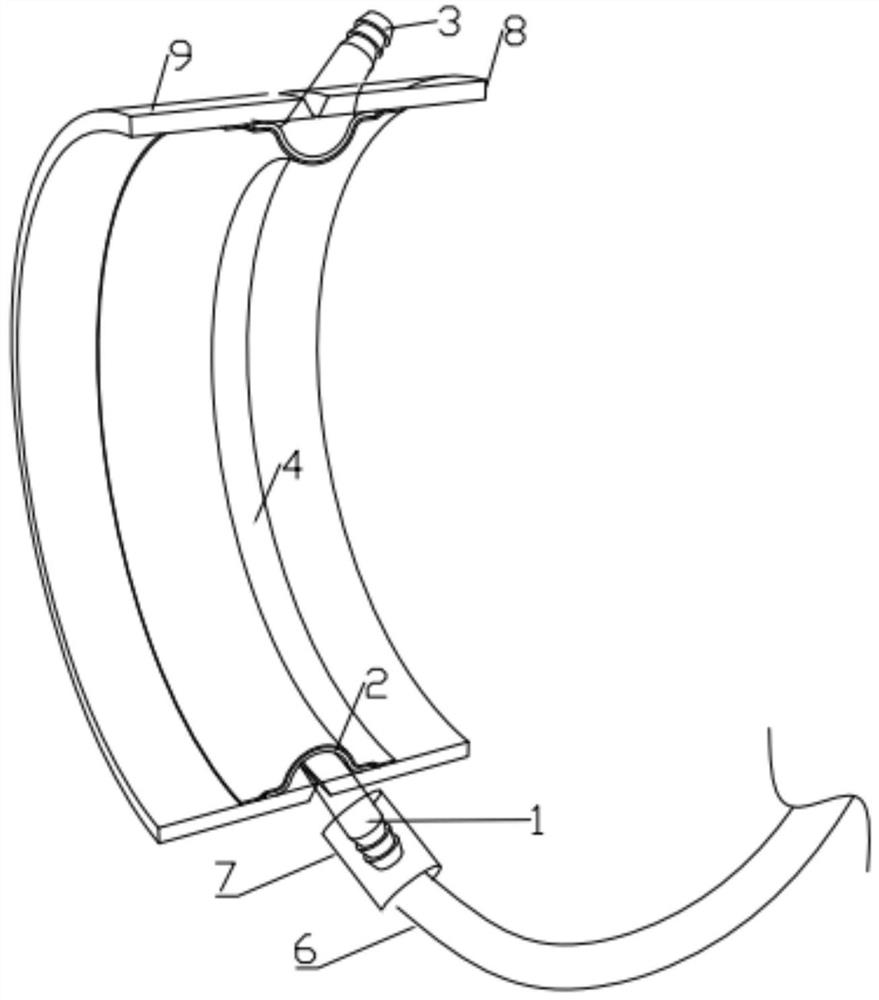

[0035] The device of the invention is used to weld the large-caliber duplex stainless steel pipeline of the ship tail gas treatment device (washing tower).

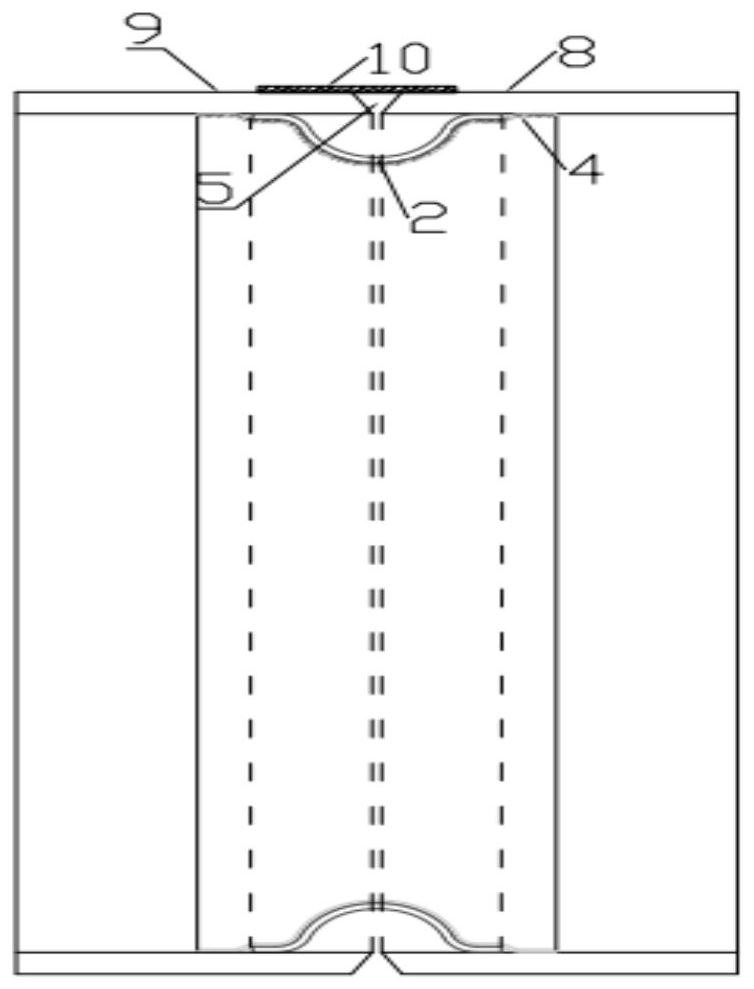

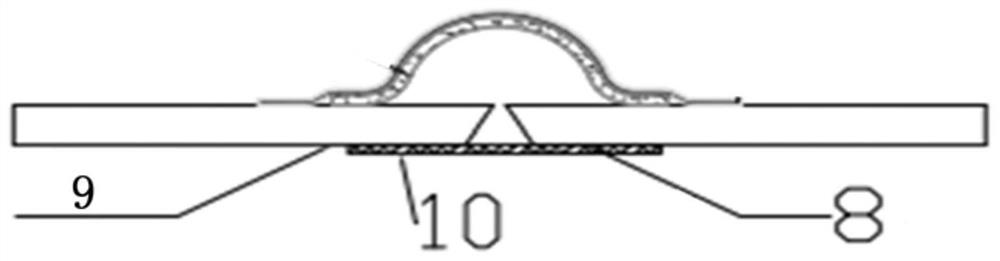

[0036] see Figure 1 to Figure 3 , when the large-diameter pipes need to be butted, assemble the pipes 8 and 9, leave the area to be welded, and stick the inflatable short groove 21 and high-temperature-resistant tinfoil tape along the direction of the area to be welded.

[0037] Install the inert gas input part 1 and the inert gas outflow part 3 on both ends of the inflatable tank assembly 2, use tin foil tape to fix the gas inlet and outlet, and ensure the sealing and gluing, so as to achieve airtight and airtight filling of argon during the welding process Purpose.

[0038] The inert gas input part 1 includes a quick connector 7 and an inflatable leather tube 6 . The two ends of the inflatable leather tube 6 are respectively connected to the quick connector 7 and the gas source device for providing argon.

[0039]Th...

Embodiment 2

[0042] Example 2 welds the pipes used to build the scrubber. The schematic diagram of the washing tower is as follows: Figure 5 shown.

[0043] Choose a pipe with a total length of 10 meters, a pipe diameter of 2.5 meters, and a pipe whose maximum straightness is controlled within the range of -3.5 to +4mm for welding.

[0044] (1) Use tooling to assemble and fix the two sections of butt pipes to ensure that the misalignment of the pipe walls is within the qualified range, and then install the device of the present invention to ensure that one end is fed in and the other end is released. The gas used is 99.99% pure argon, and the gas outlet should be kept open. state, maintain the argon flow rate to form a relatively stable air pressure between the pipeline to be welded area 5 and the shielded welding device;

[0045] (2) The gas flow rate is >25L / min. When the welding wire is deposited in a liquid state, it flows to the back of the stroke to form. Since argon is an inert g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com