Anti-blue-ray eye-protection terminal screen protective film for children

A screen protective film and anti-blue light technology, applied in the direction of film/sheet adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problem of narrow blue light absorption wavelength range and transparency of anti-blue light protective film Poor and other problems, to achieve the effect of anti-blue light, reduce blue light transmittance, excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This embodiment provides an anti-blue light eye protection terminal screen protective film for children, denoted as film 1, including:

[0082] Peeling layer: polyethylene terephthalate release film with a thickness of 48 μm;

[0083] Anti-blue light adhesive layer: anti-blue light additives and adhesives, with a thickness of 10.2 μm;

[0084] Substrate layer: polyethylene naphthalate, with a thickness of 120 μm;

[0085] Anti-scratch layer: fatty acid modified polyurethane, inorganic blue light absorber, antistatic agent, with a thickness of 4.8 μm.

[0086] The preparation method of the above-mentioned anti-blue light eye-protecting terminal screen protective film for children specifically includes:

[0087] 1) Preparation of anti-blue light additives:

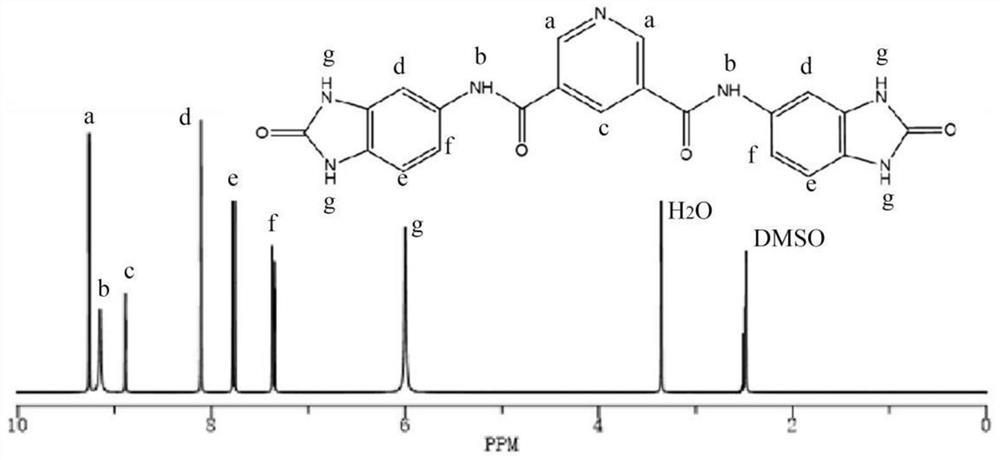

[0088] Dissolve 3g of 5-aminobenzimidazolone in a mixed solution of 30g of ethanol and water (the mixing weight ratio is 1:1), stir and add 1.7g of 3,5-pyridinedicarboxylic acid under the speed of 400r / min, and con...

Embodiment 2

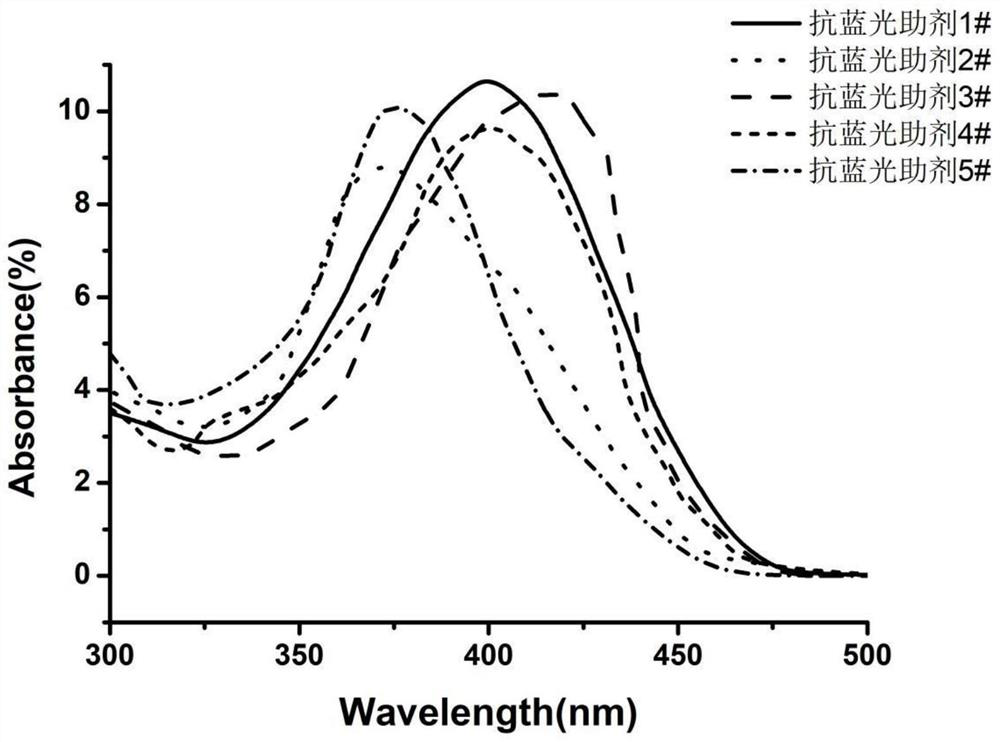

[0097] Example 2 provides a series of anti-blue light eye protection terminal screen protective films for children, which are respectively recorded as films 2 to 5. The components and preparation methods are basically the same as those in Example 1, except that the anti-blue light used in this implementation The additives are different, as shown in Table 1:

[0098] Table 1 Screen protectors for children’s terminals with anti-blue light and eye protection

[0099]

[0100]

Embodiment 3

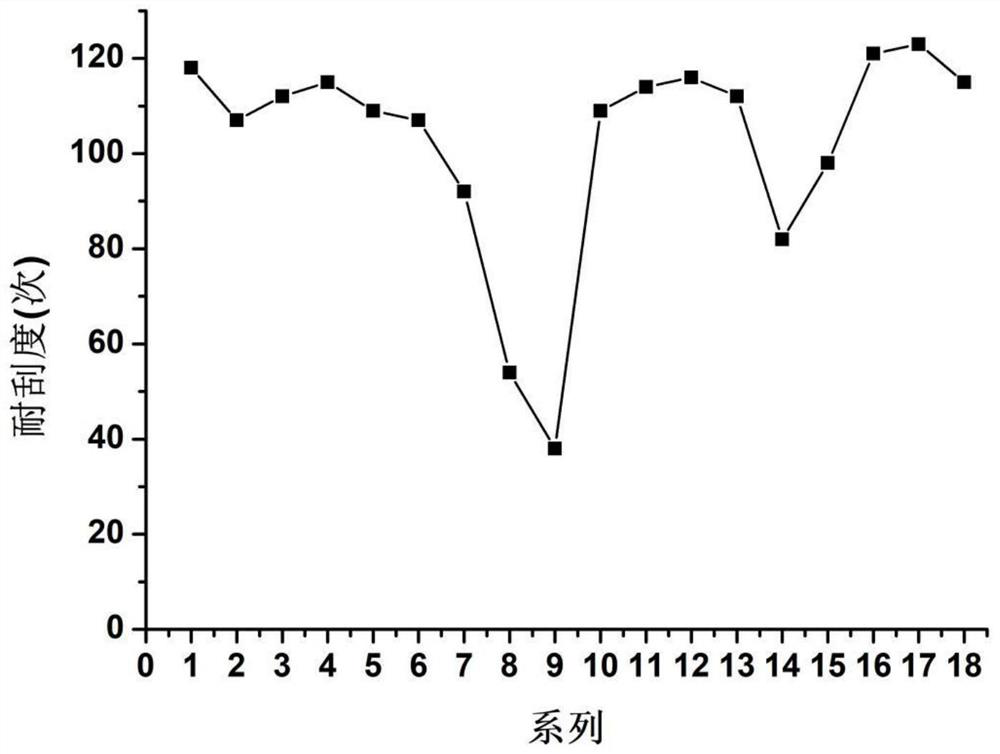

[0102] This embodiment provides an anti-blue light eye-protecting terminal screen protective film for children, denoted as Film 6. Its components and preparation method are basically the same as those in Example 1, except that in this implementation, no anti-scratch layer is added Anti-blue light additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com