Method for mixing polytetrafluoroethylene dispersion resin with high-proportion filler

A polytetrafluoroethylene and dispersing resin technology, which is applied in the field of polytetrafluoroethylene film manufacturing, can solve the problems of low uniformity of fillers, unformable and unformable calendered films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

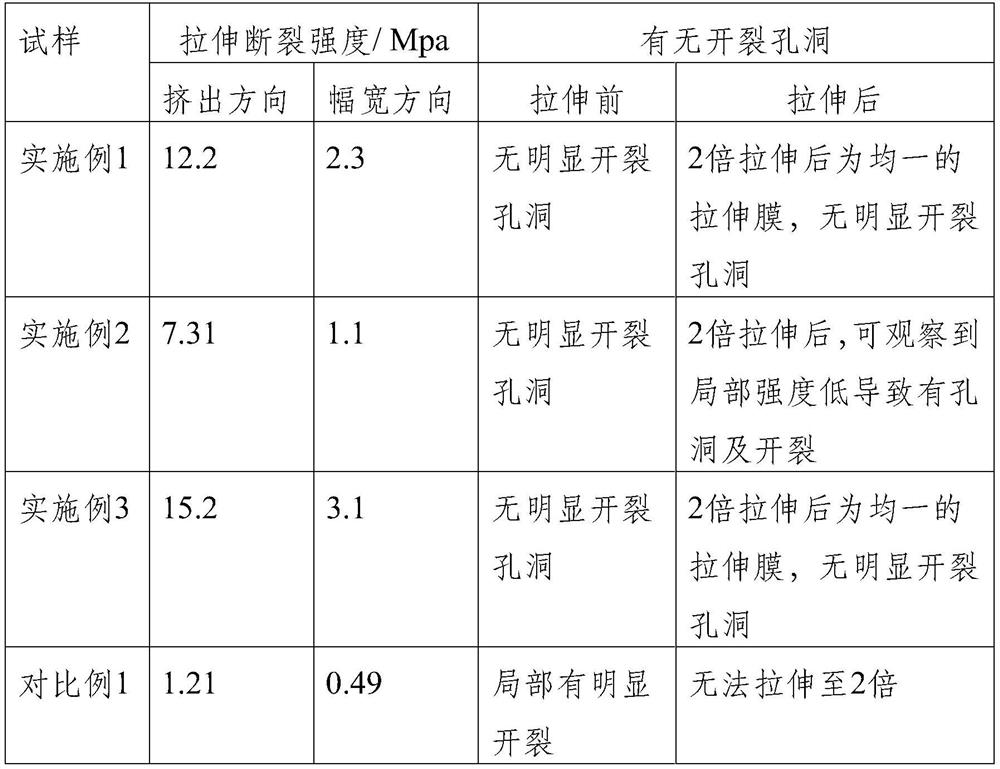

Embodiment 1

[0028] Mix 1.6kg of PTFE dispersion resin powder with 2.4kg of SiO 2 Put the powder into a three-dimensional mixer (model: SBH-20; mixing volume: 20L; spindle speed: 15r / min; motor power: 0.75Kw) and mix for 0.3h, and then use a negative pressure tube to suck the mixture into the supersonic jet milling equipment Inside, the feed rate is 1kg / h, and the ratio of the feed rate of the mixture to the maximum processing capacity of the supersonic airflow mill (YQ100-1 airflow mill) is 10%; the process parameters of the crushing equipment are: crushing pressure 0.6Mpa, supersonic jet velocity 400m / s, the pulverization time of the mixture in the supersonic airflow pulverization equipment is 6min, and the particle size of the new structure particles formed by the filler coating on the surface of the polytetrafluoroethylene particles in the discharge is 30~ 50μm;

[0029] The above-mentioned mixed material is transferred in the fluidized bed reactor (MQH-90L fluidized bed reactor), inj...

Embodiment 2

[0031] Mix 2kg of PTFE dispersion resin powder with 3kg of SiO 2 Put the powder into the three-dimensional mixer and mix for 0.3h, then use the negative pressure tube to suck the mixture into the supersonic jet milling equipment, the feeding speed is 5kg / h, the feeding speed of the mixture is the same as the maximum processing capacity of the supersonic jet milling equipment The ratio of the amount is 50%; the process parameters of the crushing equipment are: the crushing pressure is 0.6Mpa, the supersonic jet velocity is 400m / s, the crushing time of the mixture in the supersonic airflow crushing equipment is 6min, and the filler in the discharge is coated with The particle size of the new structure particles formed on the surface of PTFE particles is 80-110 μm;

[0032] The above-mentioned mixed material is transferred in the fluidized bed reactor, and the airflow is sprayed into the reactor inner cavity through the micropore at the bottom of the reactor. The feed rate of the...

Embodiment 3

[0034] Mix 2kg of PTFE dispersion resin powder with 3kg of SiO 2 Put the powder into the three-dimensional mixer and mix for 0.3h, then use the negative pressure tube to suck the mixture into the supersonic jet milling equipment. The feeding speed is 1kg / h. The ratio of the amount is 10%; the process parameters of the crushing equipment are: the crushing pressure is 0.8Mpa, the supersonic jet velocity is 500m / s, the crushing time of the mixture in the supersonic airflow crushing equipment is 6min, and the filler in the discharge is coated with The particle size of the new structure particles formed on the surface of PTFE particles is 10-30 μm;

[0035] The above-mentioned mixed material is transferred in the fluidized bed reactor, and the airflow is sprayed into the reactor inner cavity through the micropore at the bottom of the reactor. The feed rate of the S2 fluidized bed airflow mixing is 1kg / h, and the single mixing amount is 1kg. The air pressure in the fluidized bed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com