High-strength and high-modulus CPI film and preparation method thereof

A high-modulus, high-strength technology, applied in the field of CPI film, can solve the problems of complex and cumbersome manufacturing process of CPI film, lightness is not high, and achieve the effect of reducing input cost, reducing friction and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

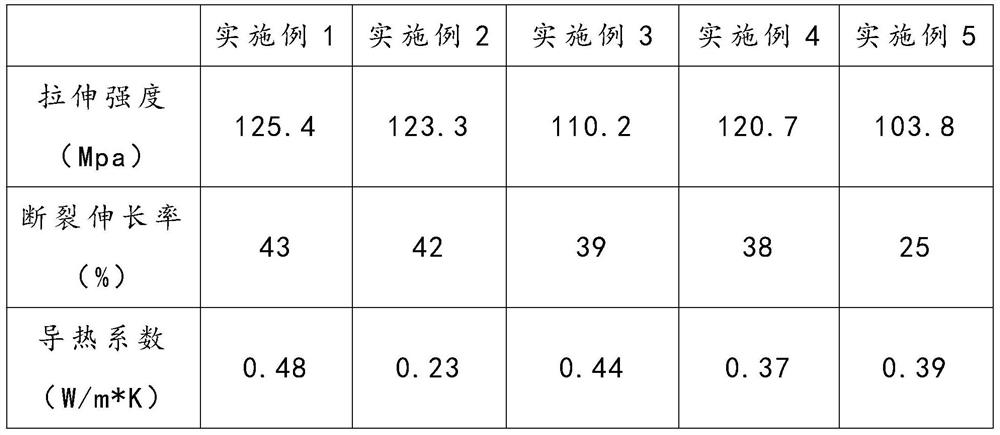

Examples

Embodiment 1

[0026] The embodiment of the present invention provides a high-strength and high-modulus CPI film, which comprises 120 parts of polyamic acid solution, 3 parts of epoxy resin, 5 parts of aluminum oxide, 11 parts of silane treatment agent and 1 part of erucamide in terms of mass fraction.

[0027] The preparation method of polyamide solution is in the existing conventional technology, and components such as pyromellitic dianhydride and biphenyltetracarboxylic dianhydride are mixed with p-phenylenediamine, diaminodiphenyl ether and 44'-diaminodiphenylmethane, etc. Aromatic diamine is obtained by polymerization reaction of diamine group as main component. The silane treatment agent is mainly composed of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0028] The CPI membrane preparation scheme is as follows:

[0029] S1. The preparation method of polyamide solution is in the existing conventional technology, components such as pyromellitic dianhydride and biphenyltetracarboxyli...

Embodiment 2

[0037] The differences between this example and Example 1 are: calculated by mass fraction, there are 124 parts of polyamic acid solution, 4 parts of epoxy resin, 5.5 parts of aluminum oxide, 13 parts of silane treatment agent, and 4 parts of erucamide.

[0038] When the epoxy resin in S2 is crushed, the temperature of the crushed equipment must be kept at 17°C. The rotation speed of the stirring rod for low-speed stirring in S4 is 32r / min, and the stirring speed in S5 is 210r / min. In S5, the temperature was raised to 77°C and the pressure was increased to 20Mpa, and the low-speed stirring time in S4 was 17 minutes.

Embodiment 3

[0040] The difference between this example and Example 1 is: calculated by mass fraction, there are 123 parts of polyamic acid solution, 5 parts of epoxy resin, 6 parts of aluminum oxide, 15 parts of silane treatment agent, and 6 parts of erucamide.

[0041] When the epoxy resin in S2 is crushed, the temperature of the crushed equipment must be kept at 18°C. The rotation speed of the stirring rod for low-speed stirring in S4 is 40r / min, and the stirring speed in S5 is 240r / min. In S5, the temperature was raised to 80°C and the pressure was increased to 30Mpa, and the low-speed stirring time in S4 was 17 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com