Resistance type micro-mechanical air pressure sensor and preparation method thereof

A technology of air pressure sensor and resistance, which is applied in the field of sensors, can solve problems such as the limit of sensor sensitivity improvement, the decrease of structural stability and reliability, and the difficulty of sensor design, so as to avoid reliability and stability problems, easy to control, and design The effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present disclosure, the present disclosure will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

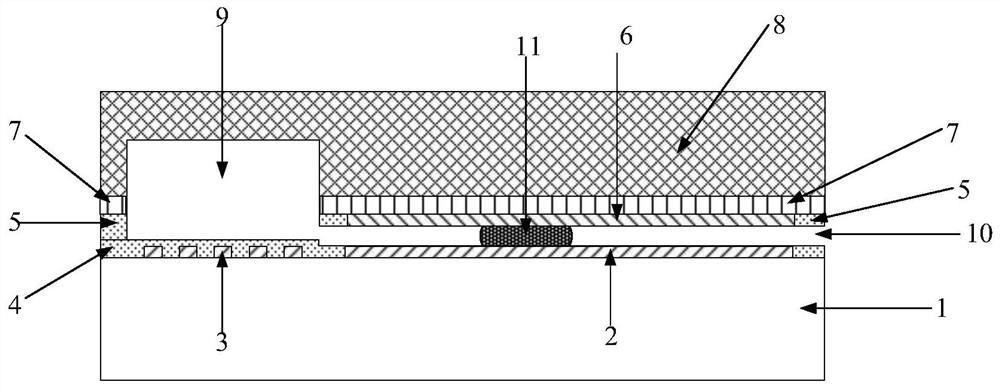

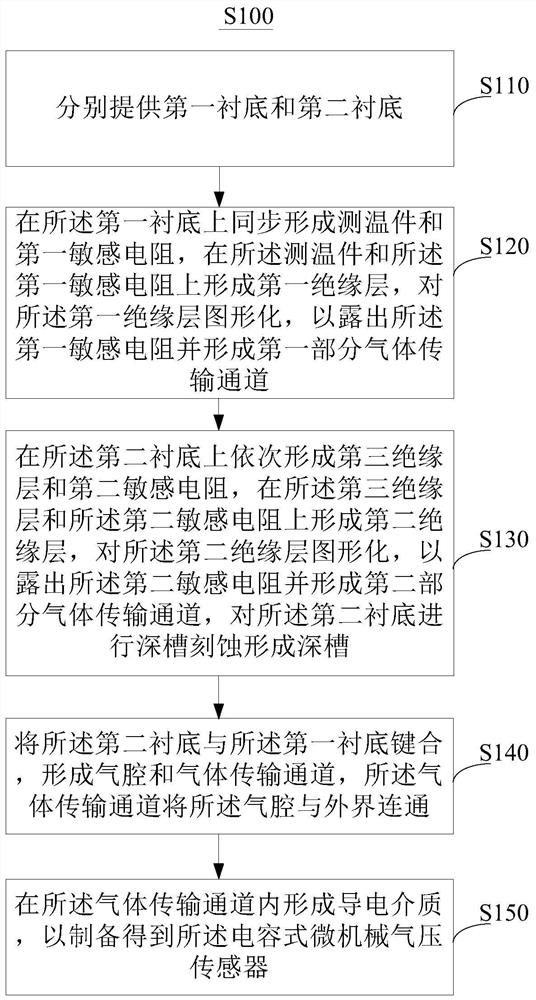

[0035] Such as figure 1 As shown, one aspect of the present disclosure relates to a resistive micromechanical air pressure sensor, including a substrate, a conductive medium 11 , a first sensitive resistor 2 and a second sensitive resistor 6 . The substrate may be made of silicon material, silicon nitride material, etc., which is not limited in the embodiments of the present disclosure. A gas cavity 9 and a gas transmission channel 10 are arranged in the substrate, and the gas transmission channel 10 communicates the gas cavity 9 with the outside. That is, if figure 1 As mentioned above, the left end of the gas transmission channel 10 communicates with the gas chamber 9 , and the right end of the gas transmission chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com