Refractive Index Sensing Device Based on Few-Mode Silicon Nitride Microring Resonator

A technology of a silicon nitride microring resonator and a silicon nitride microring resonator is applied in the field of refractive index sensing and can solve the problems of high detection limit and narrow dynamic range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

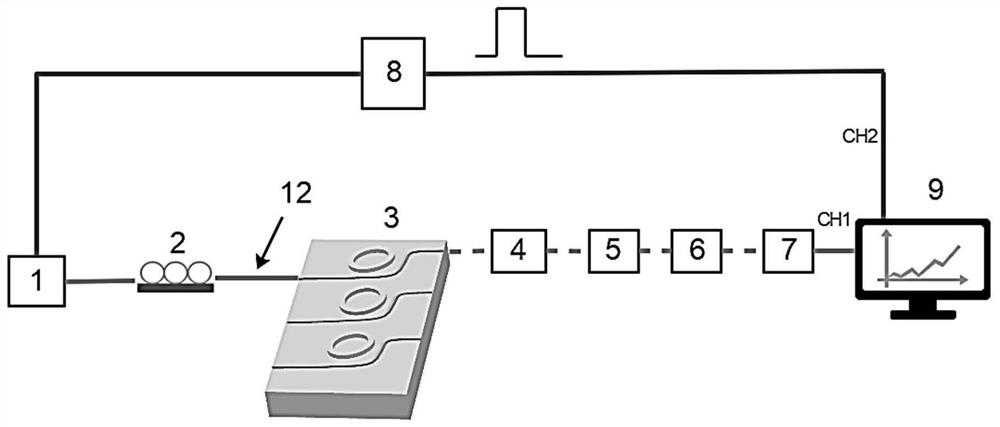

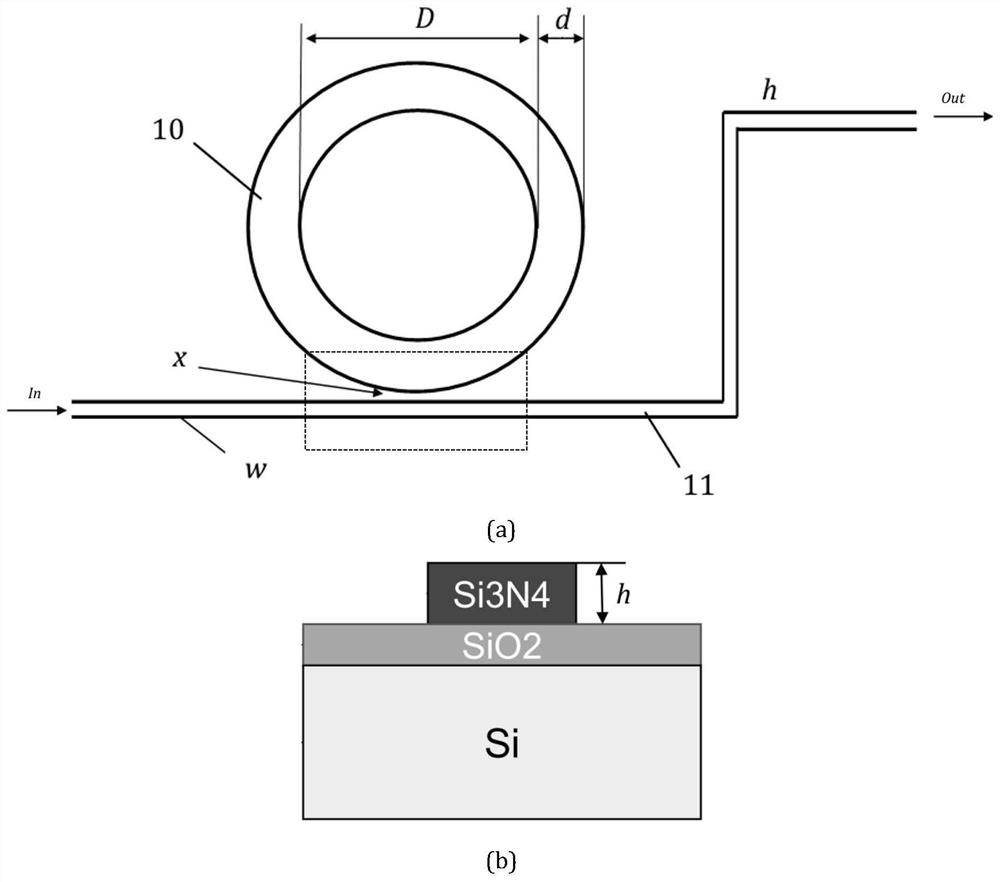

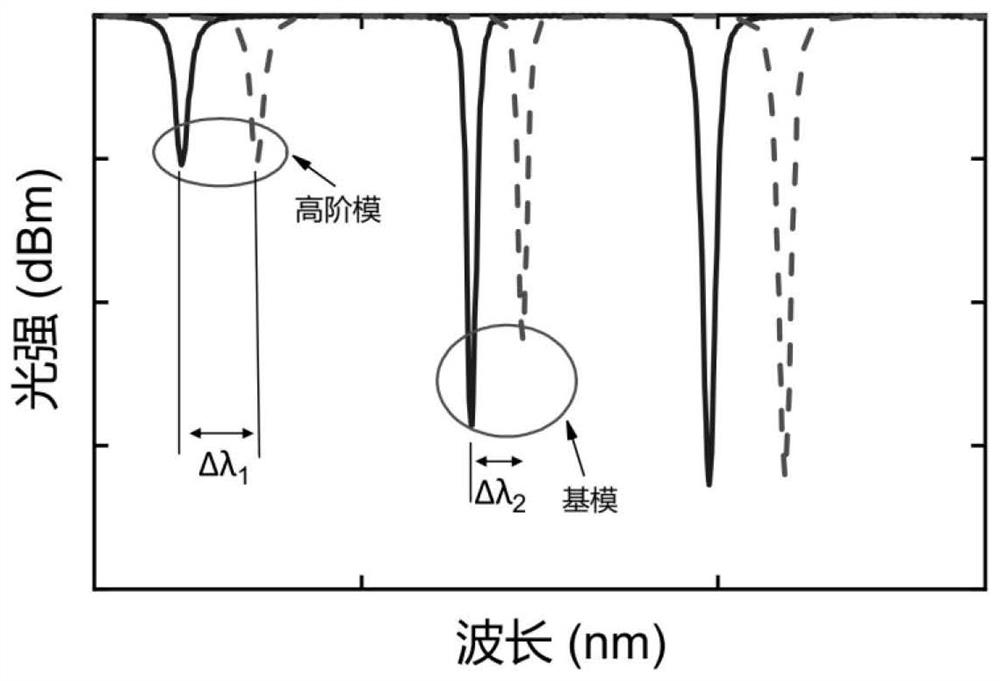

[0019] Such as figure 2 (a) and figure 2 As shown in (b), it is the few-mode silicon nitride microring resonator 3 involved in this embodiment, including: several waveguide units arranged side by side, each unit is composed of a single single-mode straight waveguide 10 for input and output and It consists of a single few-mode ring waveguide 11 for resonance, wherein: the straight waveguide and the ring waveguide in the unit are placed on the same plane and do not touch each other, the straight waveguides between the units are parallel to each other, and the two ends of a single single-mode straight waveguide are respectively as input and output.

[0020] The single single-mode straight waveguide is a Z-shaped structure.

[0021] Such as figure 2 As shown in (b), the few-mode silicon nitride microring resonator 3 is sequentially arranged on the silicon substrate and the silicon dioxide layer.

[0022] The width of the single-mode straight waveguide is 0.6 μm-1.5 μm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com