Pressure signal processing algorithm for fuel oil leakage diagnosis

A pressure signal and processing algorithm technology, which is applied in the field of fuel tank pressure signal algorithm in the fuel leakage diagnosis stage, can solve problems such as false alarms, large fluctuations, and fuel tank pressure fluctuations, so as to enhance anti-interference, improve accuracy, and avoid randomness effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] see Figure 1-Figure 4 , the pressure signal processing algorithm of fuel oil leakage diagnosis of the present invention, the process is as follows:

[0055] 1) For the fuel tank pressure signal obtained in real time, filter out unreasonable fluctuations through trend prediction and floating bandwidth limit filtering;

[0056] 2) By identifying the peak and trough of the filtered fuel tank pressure, identify the periodically fluctuating peak and trough signals, evaluate the stable state of the fuel tank pressure signal, and identify the starting point of the pressure gradient calculation;

[0057] 3) Classify the initial fuel tank pressure signal into:

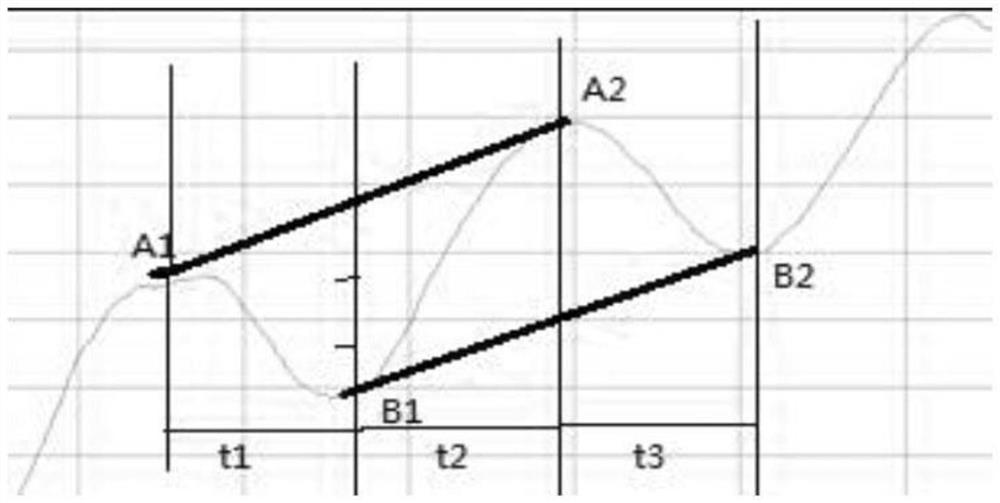

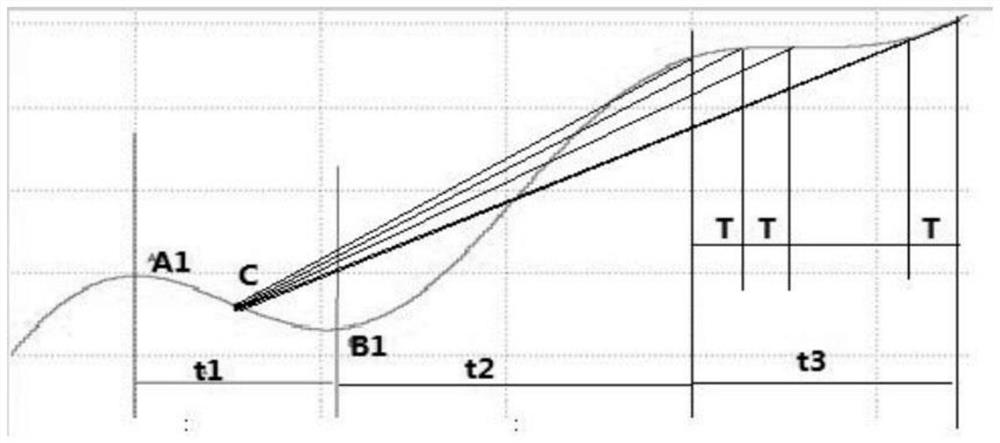

[0058] (1) The pressure fluctuates upward, with obvious troughs and peaks, and the fluctuation energy has the characteristics of convergence, so two peaks and two troughs are identified respectively, and the slopes are calculated respectively, and then the average value of the slopes is used for diagnosis; figure 1 ; ...

Embodiment 2

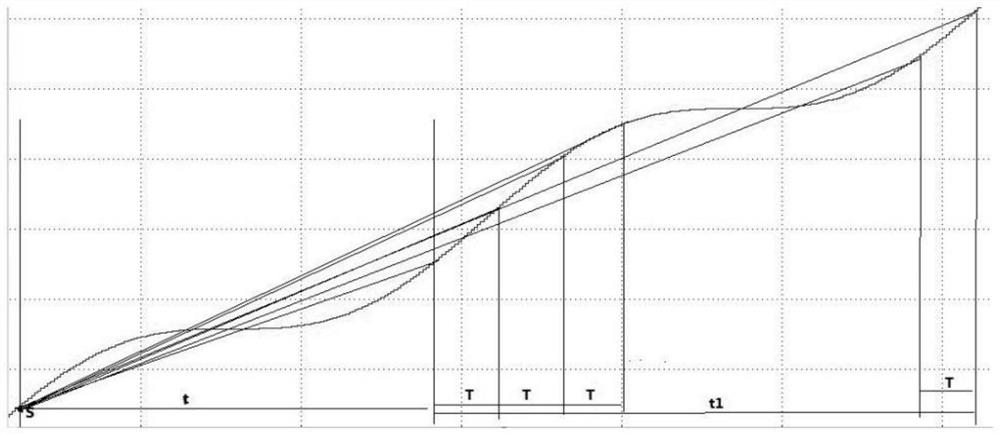

[0064] The pressure signal processing algorithm for fuel leakage diagnosis in this embodiment is different from that in Embodiment 1 in that the gradient average value is calculated multiple times within a certain period of time, so as to effectively avoid the random error of a single signal.

Embodiment 3

[0066] The pressure signal processing algorithm of fuel leakage diagnosis in this embodiment is different from Embodiment 1 or Embodiment 2 in that it predicts the trend of the fuel tank pressure signal and filters the floating bandwidth limit value: the next The measured pressure at all times, combined with the average value of the absolute difference between the two points as the dynamic bandwidth to calculate the upper limit and lower limit of the fuel tank pressure signal, and dynamically correct the true value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com