Sealing stock bin

A technology for sealing silos and silos, which is applied in the direction of thin material processing, containers, coatings, etc., can solve the problems of increasing production costs, prone to unqualified products, and untimely loading of materials, so as to reduce production costs and avoid printing The effect of material volatilization and energy demand reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

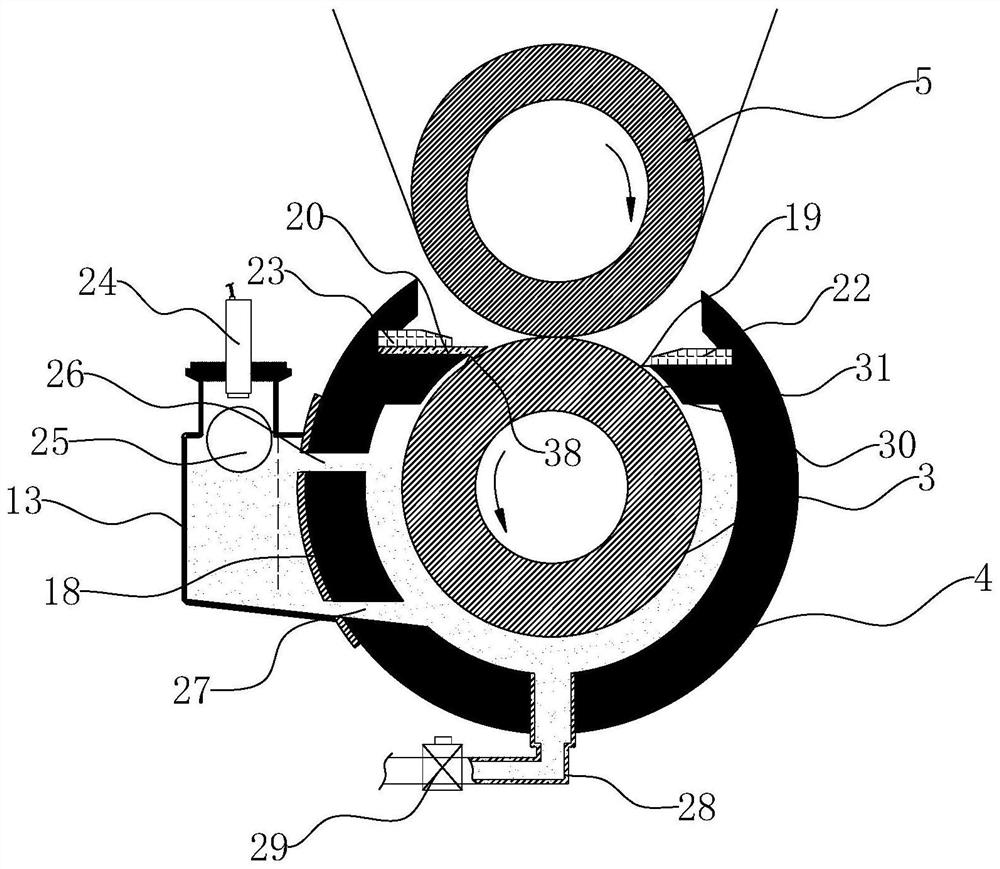

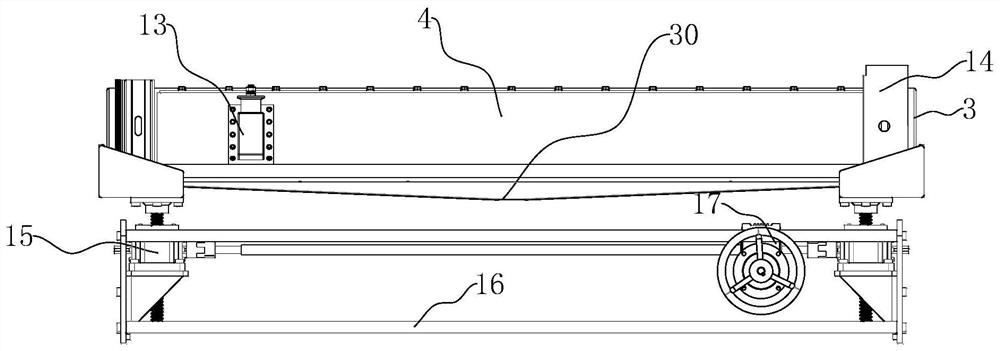

[0030] Please refer to Figure 2-5 As shown, the present embodiment provides a sealed silo 4, including a silo 4 with a coating port on the top and an anilox roller 3 that is rotatably connected to the silo 4 at both ends, and one side of the anilox roller 3 passes through the The coating port extends to the outside of the feed bin 4, one side of the coating port is provided with a scraper blade 19 connected to the anilox roller, and the other side is provided with a PTFE sealing plate 20 connected to the anilox roller 3, and the scraper blade Sheet 19 is positioned at the feed side of the gravure printing or coating film of silo 4, and the tetrafluoro sealing plate 20 is positioned at the film discharging side, and described doctor blade 19, anilox roller 3, tetrafluoro sealing plate 20 jointly will coating The mouth is closed.

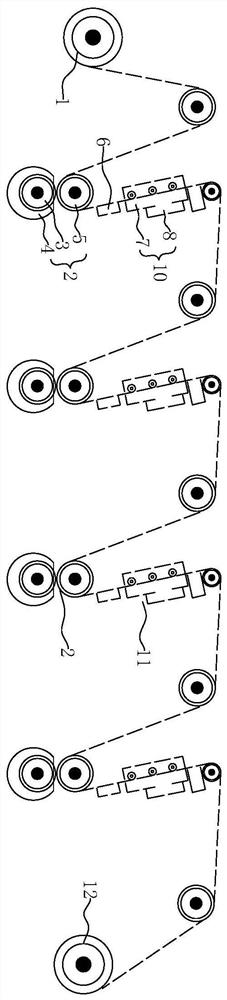

[0031] When in use, the sealed silo 4 can be placed on the production line for use, and a production line that can be coated with a low boiling poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com