Application of ethoxylated fat protective layer formula in preparation of football surface layer

A technology of protective layer and ethoxylation, applied in coating and other directions, can solve the problems of limited production capacity and production space cost, high odor of raw materials in printing process, and increased labor demand, etc., to achieve low cost, durable adhesion, and productivity. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

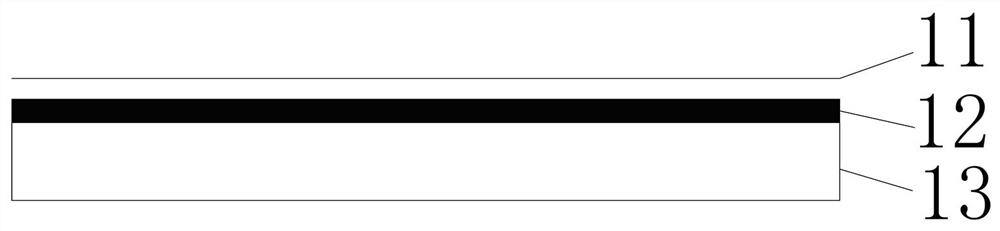

[0040] Example 1: see figure 2 , when an ethoxylated fat protective layer is added under the digital printing layer, the protective effect of the ethoxylated fat protective layer on the bottom surface of the printing layer is strengthened by 75%, and the impact resistance strength of the surface of the digital printing layer remains unchanged by 25%.

Embodiment 2

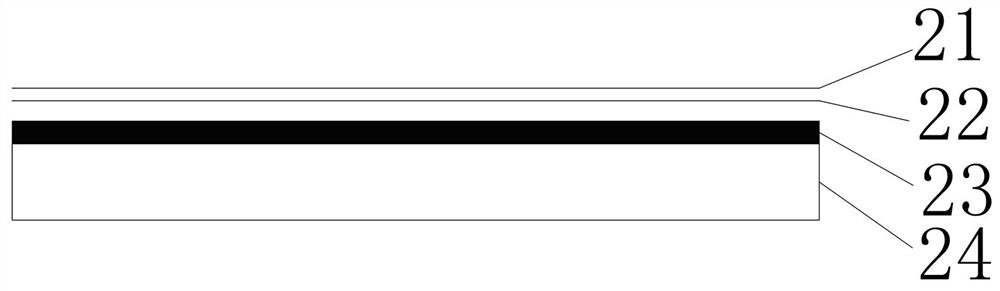

[0041] Example 2: see image 3 , when adding an ethoxylated fat protective layer above the digital printing layer, the protective effect of the ethoxylated fat protective layer on the surface of the printing layer was strengthened by 75%, and the adhesion strength of the bottom surface of the digital printing layer remained unchanged by 25%.

Embodiment 3

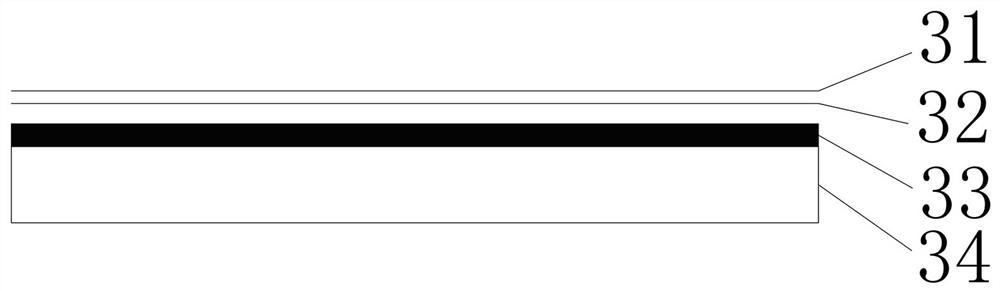

[0042] Example 3: see Figure 4 , above and below the digital printing layer, an ethoxylated fat protective layer is added for protection. Under the protection of the ethoxylated fat protective layer, the pattern adhesion of the digital printed layer and the durable life of the surface layer isolation protection exceed those of Examples 2 and 3. times the level.

[0043] It can be seen from the above examples that the use of the ethoxylated fat protective layer of the present invention, in addition to improving the adhesion of digital printing and making it more durable, can fully meet the impact resistance standard of professional football; at the same time, it can also directly replace screen printing, saving labor. Take the route of environmental protection and automated production. The technical process of the ethoxylated fat protective layer of the present invention is simple, the yield is high, the cost is lower and the production efficiency is higher.

[0044] From th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com