Electrolysis control circuit, disinfectant manufacturing device and electrolysis control method

A technology of control circuit and control method, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of low electrolysis efficiency and electromagnetic noise, and achieve the effect of high electrolysis efficiency and improvement of electrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

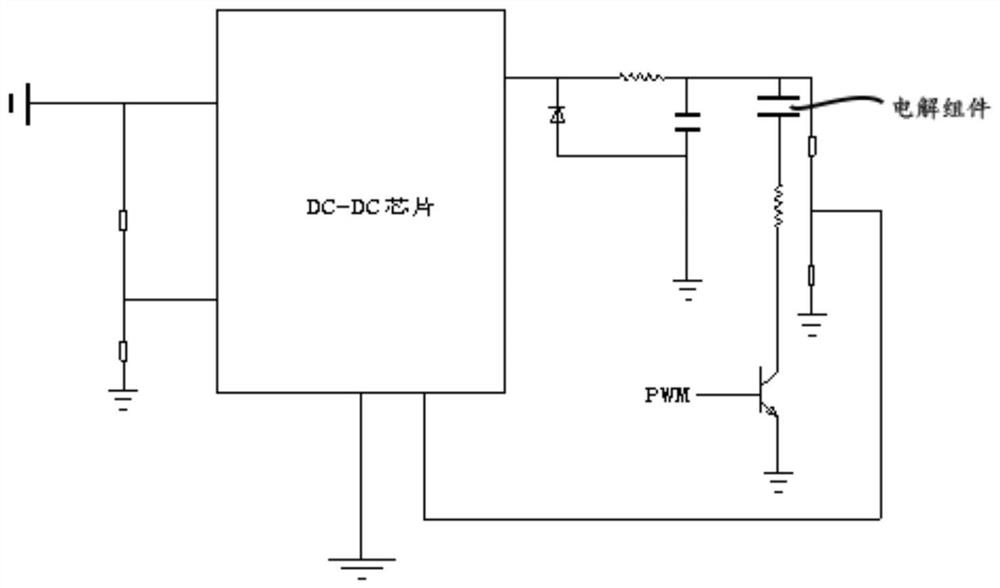

Method used

Image

Examples

Embodiment 1

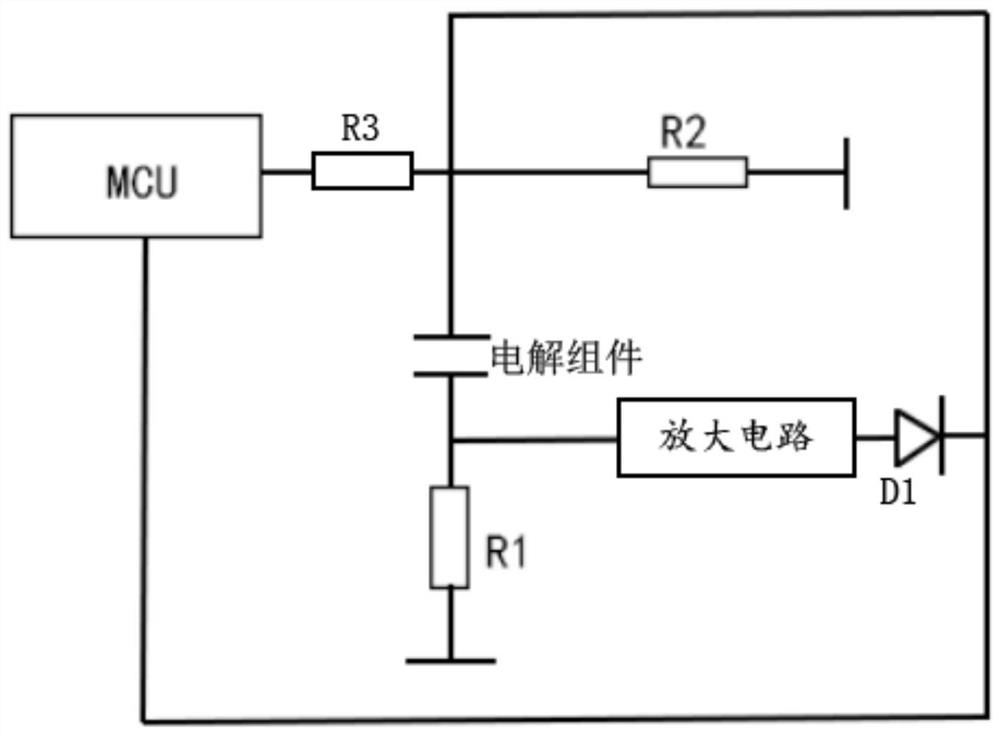

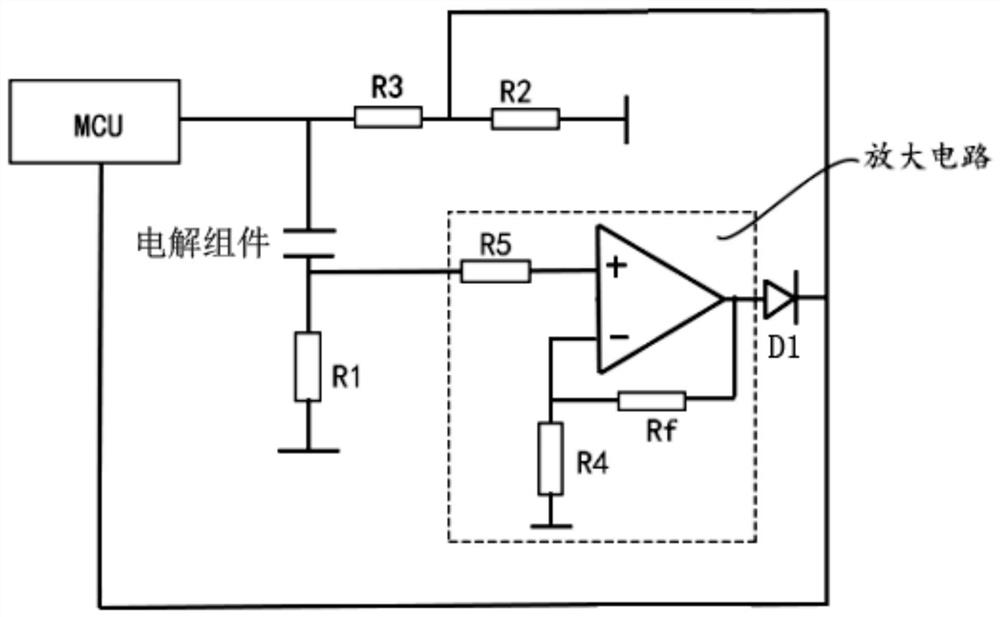

[0045] Such as figure 2 As shown, the embodiment of the present invention provides an electrolysis control circuit, which includes: a control chip MCU, an electrolysis component, a second resistor R2 and a diode D1.

[0046] The control chip MCU is provided with an output port and a feedback port, the output port is used for outputting a voltage, and the feedback port is used for receiving a feedback signal. The electrolysis assembly is composed of a first electrode and a second electrode, the first electrode is connected to the output port, the second electrode is grounded through the first resistor R1, and the first electrode and the second electrode are suitable for being placed in the electrolyte for electrolysis. One end of the second resistor R2 is connected to the first electrode and the other end is grounded, and the feedback port is connected between the second resistor R2 and the output port. The anode of the diode D1 is connected between the second electrode and t...

Embodiment 2

[0061] An embodiment of the present invention also provides a device for producing disinfectant, including the electrolysis control circuit as described in any one of the above embodiments.

[0062] Beneficial effect: with such arrangement, the electrolysis process starts with the maximum current after starting, and at this time, the voltage of the first resistor is higher than the voltage of the second resistor, so that the diode is turned on. At this time, the electrolysis efficiency is higher. As the electrolysis progresses, the current decreases gradually, and the voltage gradually increases. At this time, the diode is cut off. When the current flowing through the electrode sheet is less than the preset current and the voltage across the electrode sheet is equal to the preset voltage, the electrolysis is performed at the preset maximum voltage. The solution is electrolyzed until the end of electrolysis. Therefore, the electrolysis current can be better controlled, electro...

Embodiment 3

[0064] The embodiment of the present invention also provides an electrolysis control method, which is applied to the disinfectant manufacturing device as described in the above embodiment, and the electrolysis control method includes:

[0065] S1. Obtain a feedback voltage from the feedback port;

[0066] S2. Judging whether the feedback voltage is reduced to a preset feedback voltage;

[0067] S3. If the feedback voltage drops to a preset feedback voltage, control the output voltage to rise to a preset maximum voltage.

[0068] The electrolysis control circuit of the disinfectant solution manufacturing device is provided with a control chip MCU, and the feedback port of the control chip MCU is used to obtain a feedback signal. In this embodiment, the feedback voltage is used as the feedback signal for illustration.

[0069] Before the electrolysis, put the first electrode and the second electrode into the electrolyte, after the electrolysis starts, the output port of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com