A water vapor condensation recovery water-saving sound-absorbing cooling tower

A technology of condensation recovery and water vapor, which is applied in the field of cooling towers, can solve problems such as noise, waste of water resources, and noise pollution, and achieve the effects of avoiding deformation and damage, speeding up condensation processing, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

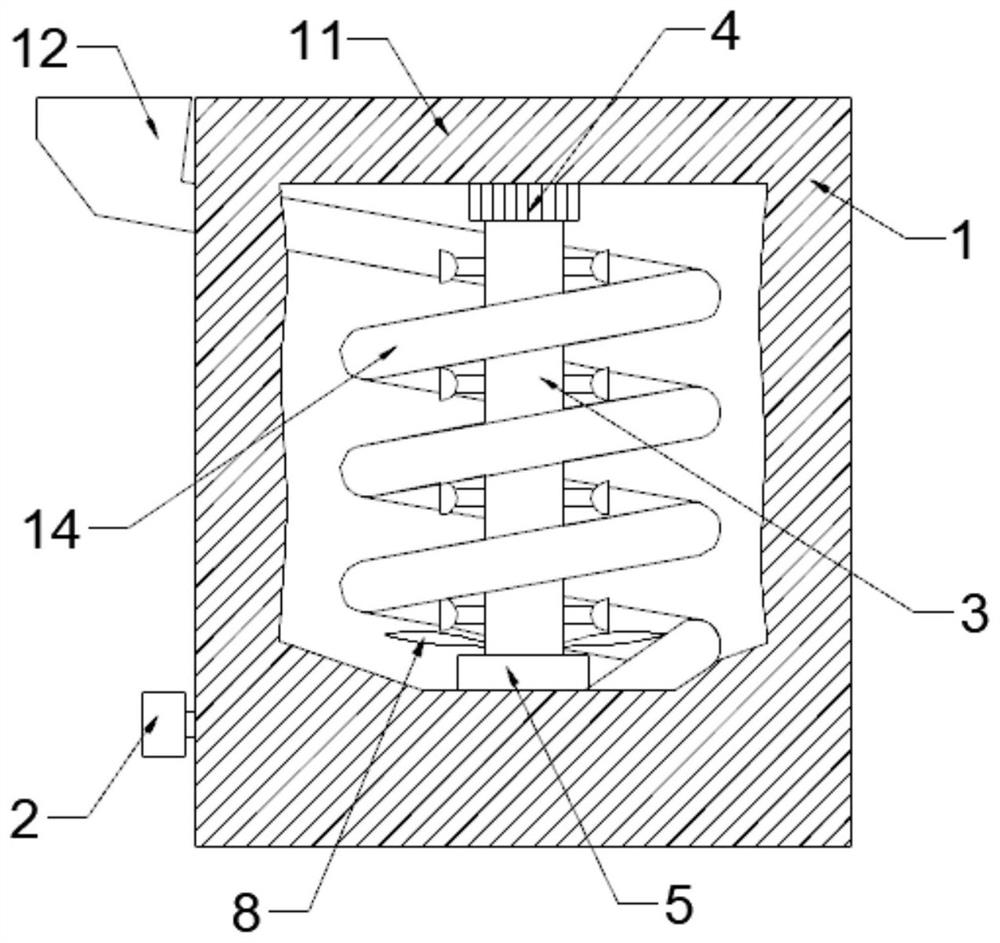

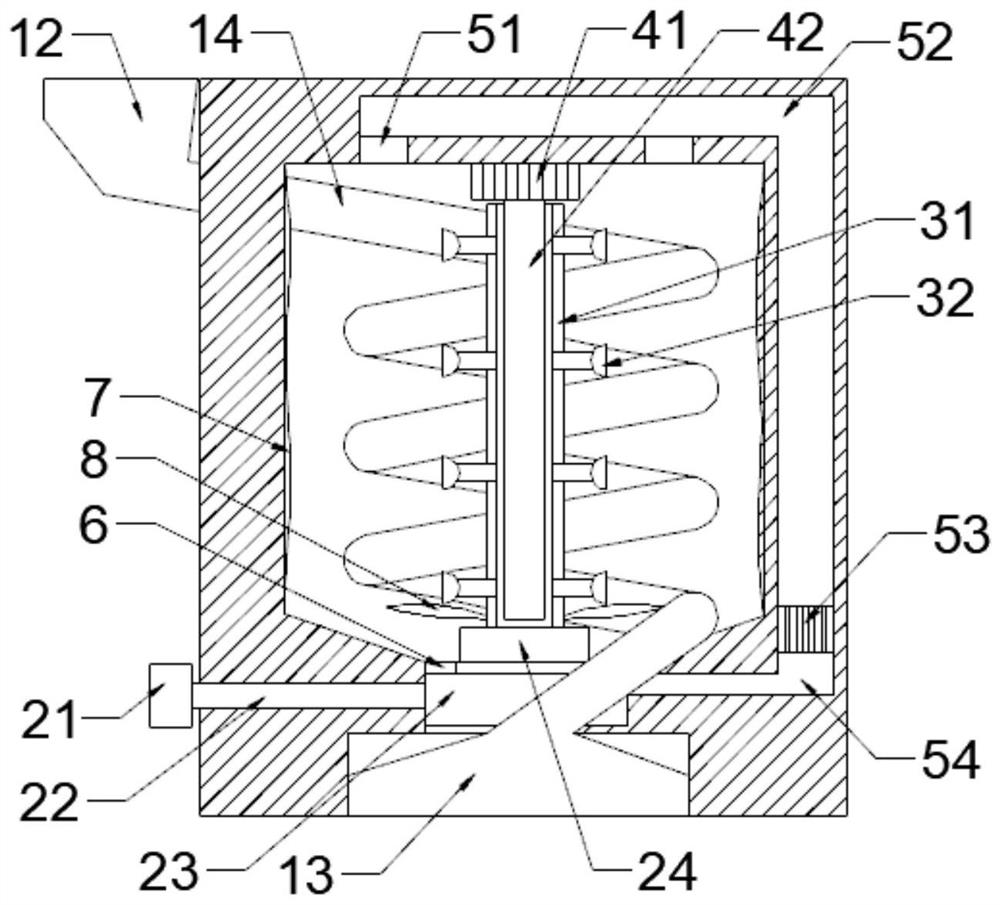

[0034] refer to Figure 1-2 , a water vapor condensation recovery water-saving sound-absorbing cooling tower, the cooling tower includes:

[0035] tower body 1;

[0036] Water supply mechanism 2, which is used to provide water source for internal cooling of tower body 1;

[0037] The water spray mechanism 3, the water spray mechanism 3 comprises a water inlet ring pipe 31 and a nozzle 32, one end of the water inlet ring pipe 31 is rotationally connected with the water supply mechanism 2, a plurality of nozzles 32 are fixedly installed on the outer wall of the water inlet ring pipe 31, and The center of the ring pipe 31 is a midpoint annular array to form a group of nozzles 32 rings, and multiple groups of nozzles 32 rings are evenly fixed on the water inlet ring pipe 31 in the vertical direction;

[0038] A rotating mechanism 4, the rotating mechanism 4 is used to rotate the water inlet ring pipe 31;

[0039] The water vapor condensing device 5, the water vapor condensing d...

Embodiment 2

[0047] refer to Figure 1-4 , different from Embodiment 1, the inner wall of the shell 11 is fixedly equipped with a sound-absorbing layer 7, the outer layer of the sound-absorbing layer 7 is made of elastic material, and the inside is filled with liquid or gas, and the outer layer of the sound-absorbing layer 7 can be sound-absorbed by a certain The characteristics of high temperature resistance and corrosion resistance can avoid damage to the sound-absorbing layer 7 caused by long-term cooling.

[0048] In this embodiment, a large amount of liquid droplets will be produced during the spray cooling process of the nozzle 32, and the liquid droplets will hit the inner wall of the housing 11 during spraying. The noise generated by the collision is eliminated, which plays a role in muting the cooling process, and at the same time prevents the shell 11 from being deformed or damaged in the long-term impact of the liquid droplets, and plays a role in protecting the shell 11 .

Embodiment 3

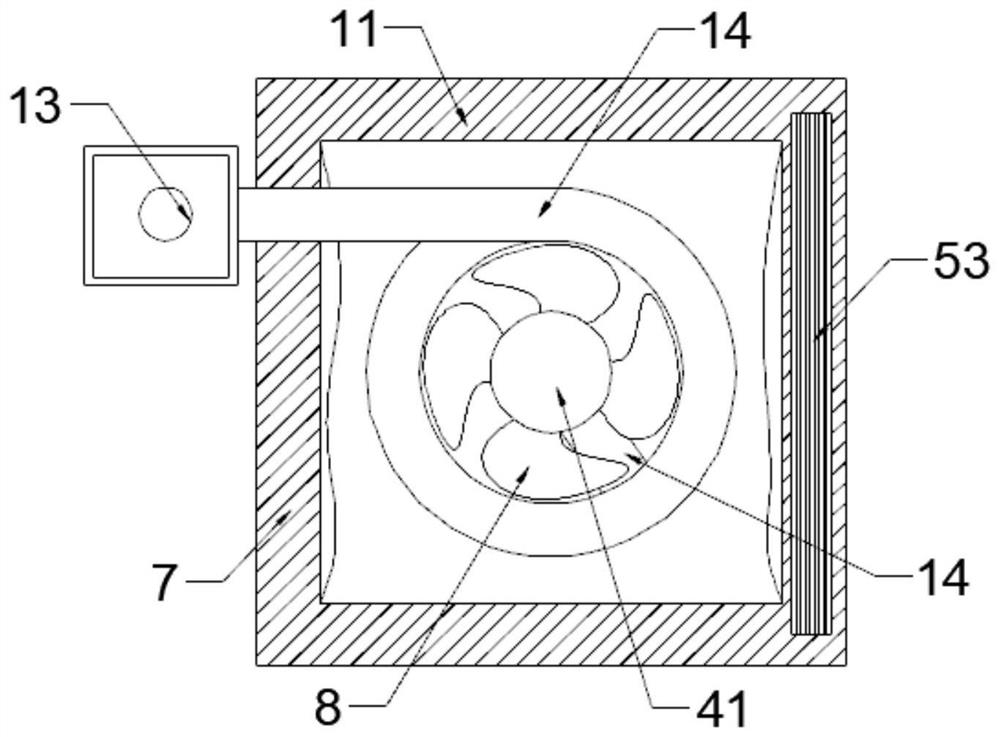

[0050] refer to Figure 3-4 , different from Embodiment 1, four fan blades 8 are fixedly connected to the end of the water inlet ring pipe 31 close to the water pump 24. It will affect the normal cooling of the cooling pipe 14, and the air flow caused by the rotation of the fan blade 8 is from bottom to top.

[0051] In this embodiment, when the nozzle 32 cools the cooling pipe 14, a large amount of water vapor will remain inside the tower body 1, which is not conducive to the condensation and recovery of water vapor. The fan blade installed at the bottom of the water inlet ring pipe 31 8. With the rotation of the water inlet ring pipe 31, the air flow inside the tower body 1 is changed, and the water vapor inside the tower body 1 moves toward the air inlet 51, which ensures effective cooling of the water vapor and prevents the inside of the tower body 1 from The pressure is too high, causing the shell 11 to deform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com