Preparation method of bonded samarium-cobalt magnet and vacuum stirring device of bonded samarium-cobalt magnet

A samarium-cobalt magnet and vacuum stirring technology, which is applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of acetone solvent volatilization and environmental pollution, and achieve accelerated mixing, prevention of environmental pollution, and reduction of environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a bonded samarium cobalt magnet, the bonded samarium cobalt magnet is composed of 97wt% samarium cobalt magnetic powder, 1.95wt% thermosetting binder and 0.05wt% lubricant, the preparation method of the bonded samarium cobalt magnet Include the following steps:

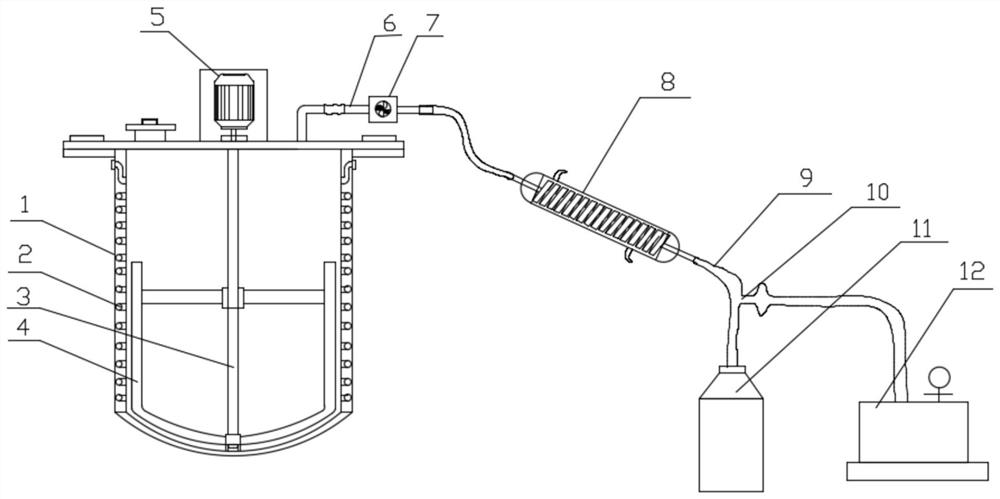

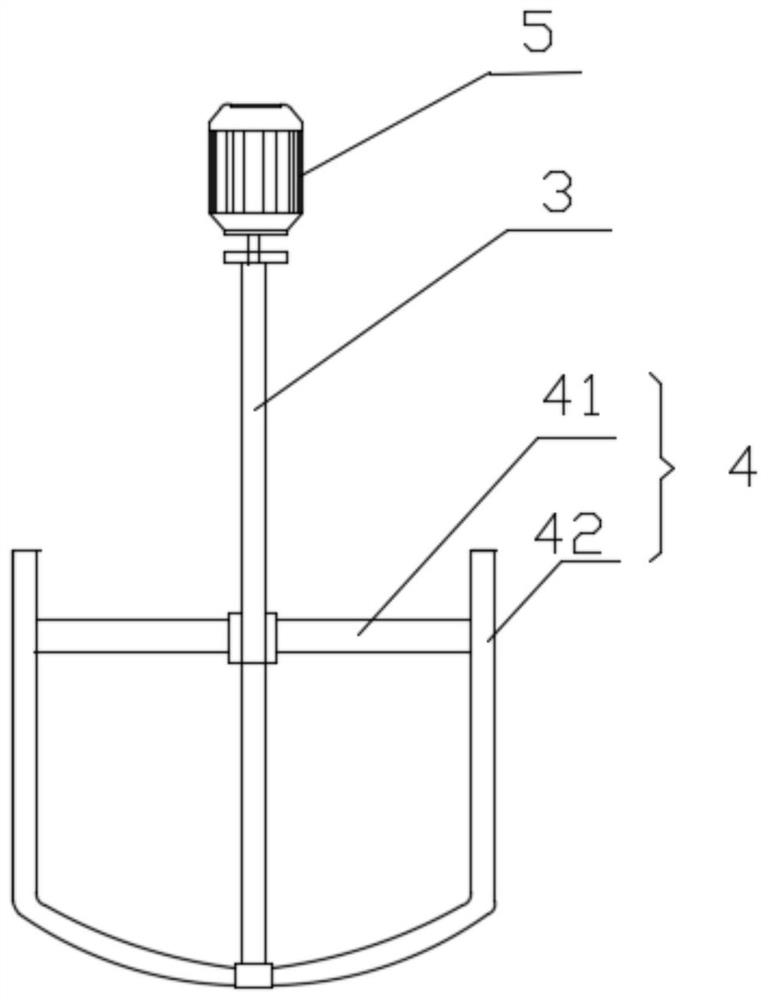

[0032] 1) Send 9.7kg of samarium-cobalt magnetic powder and acetone solution dissolved with 0.195kg of epoxy resin AB glue to the vacuum stirring device in turn, mix evenly, heat during the stirring process, the heating temperature is 35-40°C, and start vacuuming at the same time The device is used to recover acetone. After the acetone in the stirring device is completely volatilized, take out the product, dry it in an oven at 80°C, and then crush it with a crusher and pass it through a 100-120 mesh sieve to obtain rubber powder;

[0033] 2) the rubber powder obtained in step 1) is uniformly mixed with 0.005kg zinc stearate, and sent into a molding machine to be pressed into a ring sampl...

Embodiment 2

[0038] A preparation method of a bonded samarium cobalt magnet, the bonded samarium cobalt magnet is composed of 97.6wt% samarium cobalt magnetic powder, 2.3wt% thermosetting binder and 0.1wt% lubricant, the preparation of the bonded samarium cobalt magnet The method includes the following steps:

[0039] 1) Send 9.76kg of samarium-cobalt magnetic powder and acetone solution dissolved with 0.23kg of epoxy resin AB glue to the vacuum stirring device in turn, mix evenly, heat during the stirring process, the heating temperature is 35-40°C, and start vacuuming at the same time The device is used to recover acetone. After the acetone in the stirring device is completely volatilized, take out the product, dry it in an oven at 80°C, and then crush it with a crusher and pass it through a 100-120 mesh sieve to obtain rubber powder;

[0040] 2) the rubber powder obtained in step 1) is uniformly mixed with 0.1kg zinc stearate, and sent into a molding machine to be pressed into a ring sa...

Embodiment 3

[0045] A preparation method of a bonded samarium cobalt magnet, the bonded samarium cobalt magnet is composed of 98wt% samarium cobalt magnetic powder, 2.5wt% thermosetting binder and 0.5wt% lubricant, the preparation method of the bonded samarium cobalt magnet Include the following steps:

[0046] 1) Send 9.8kg of samarium-cobalt magnetic powder and acetone solution dissolved with 0.25kg of epoxy resin AB glue to the vacuum stirring device in turn, mix evenly, heat during the stirring process, the heating temperature is 35-40°C, and start vacuuming at the same time The device is used to recover acetone. After the acetone in the stirring device is completely volatilized, take out the product, dry it in an oven at 80°C, and then crush it with a crusher and pass it through a 100-120 mesh sieve to obtain rubber powder;

[0047]2) the rubber powder obtained in step 1) is uniformly mixed with 0.05kg zinc stearate, and sent into a molding machine to be pressed into a ring sample;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com