A near-field bolometric tuner based on DC voltage biased graphene

A DC voltage and near-field radiation technology, applied in indirect heat exchangers, instruments, lighting and heating equipment, etc., can solve the problems of unavailability in actual production and excessive magnetic field strength, and achieve excellent near-field thermal radiation modulation capabilities, Easy to generate and manipulate, enhance the effect of near-field thermal radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

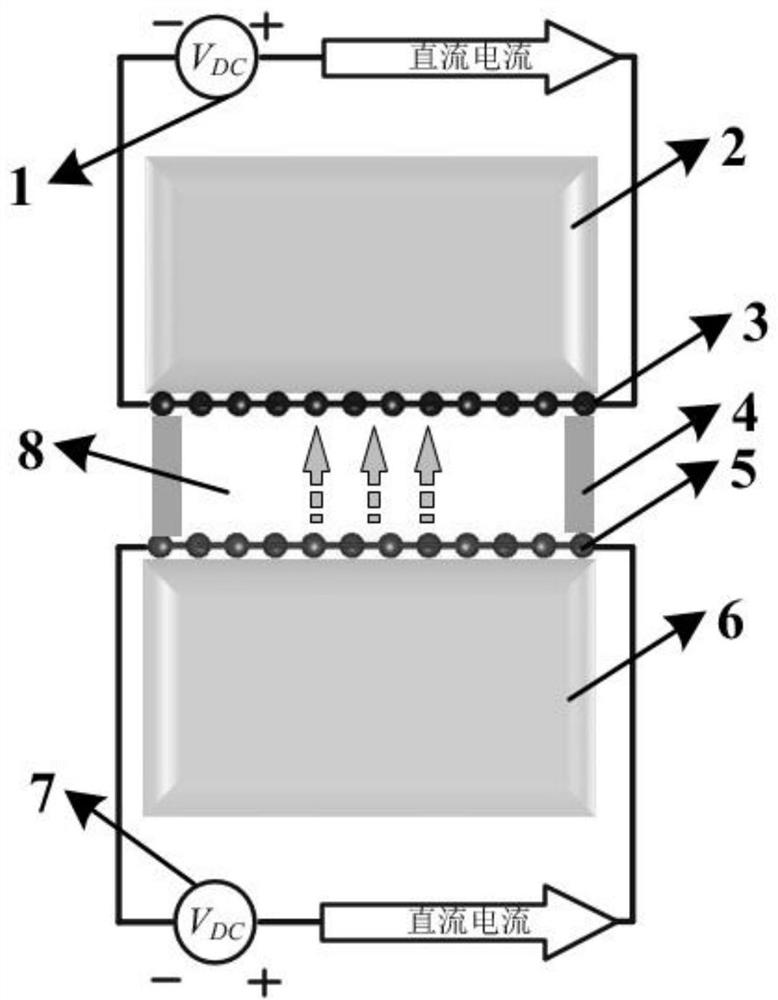

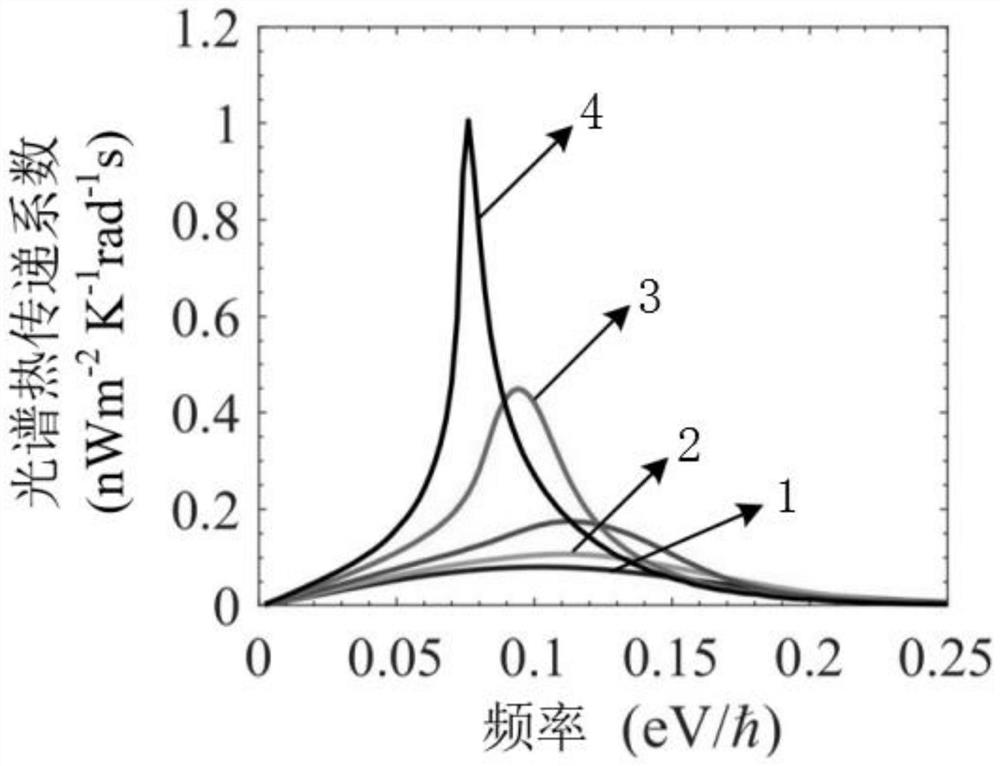

[0025] Specific implementation mode one (refer to figure 1 ): a near-field radiance tuner based on DC voltage bias graphene of the present embodiment is composed of a receiving end compound structure, a transmitting end compound structure and a spacer 4 arranged between the two, the receiving end compound structure and The spacer 4 forms a vacuum gap 8 between the composite structures of the transmitting end; the composite structure of the receiving end and the composite structure of the transmitting end are identical and symmetrically arranged with respect to the spacer 4, and the composite structure of the receiving end is controlled by a DC voltage generator at the receiving end 1. The receiving end substrate 2 and the receiving end graphene coating 3 are composed. The receiving end graphene coating 3 is plated on the lower surface of the receiving end substrate 2. The receiving end DC voltage generator 1 communicates with the receiving end graphene coating 3 through wires a...

specific Embodiment approach 2

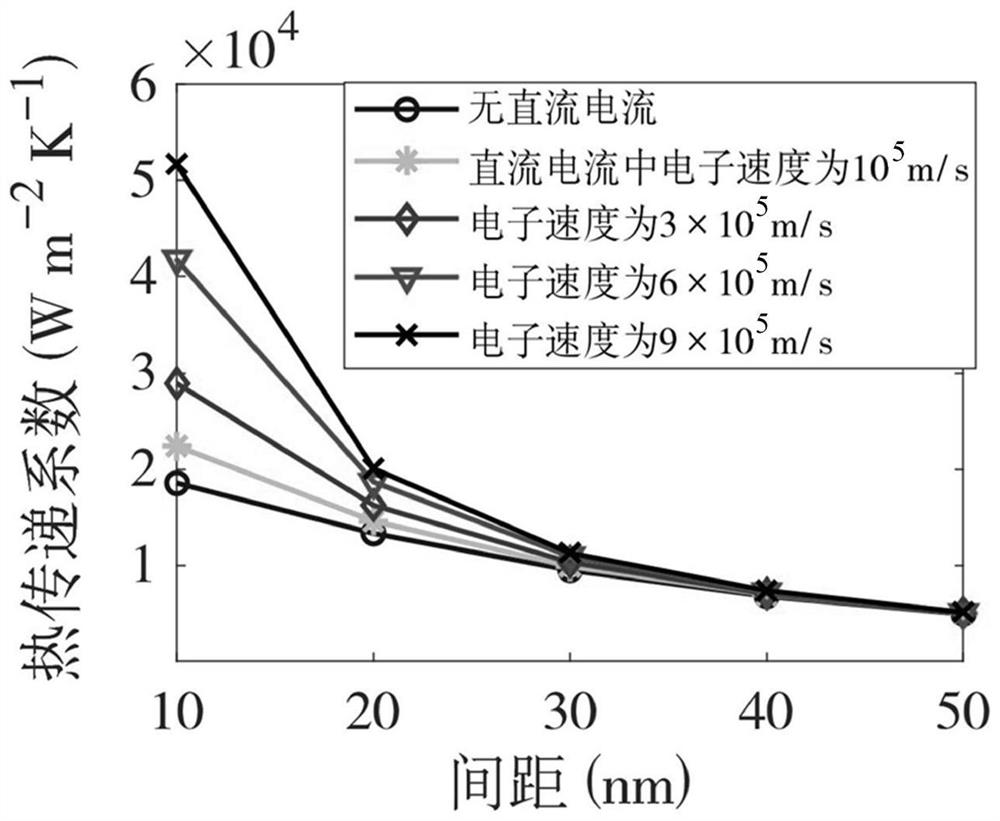

[0031] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the vertical distance between the composite structure at the receiving end and the composite structure at the transmitting end is 20 nm, that is, the other steps and parameters described in the height of the spacer 4 are related to the specific embodiment One is the same.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the vertical distance between the composite structure at the receiving end and the composite structure at the transmitting end is 30 nm, that is, the other steps and parameters described in the height of the spacer 4 are related to the specific embodiment. One is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com