Boiling heat exchange experimental device for promoting uniform heating of low-temperature mixed working medium

A low-temperature mixed working fluid and uniform heating technology, which is applied in the directions of measuring devices, material thermal development, and material thermal conductivity, can solve the problems of lack of experimental research on the heat transfer characteristics of multiple mixed working fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

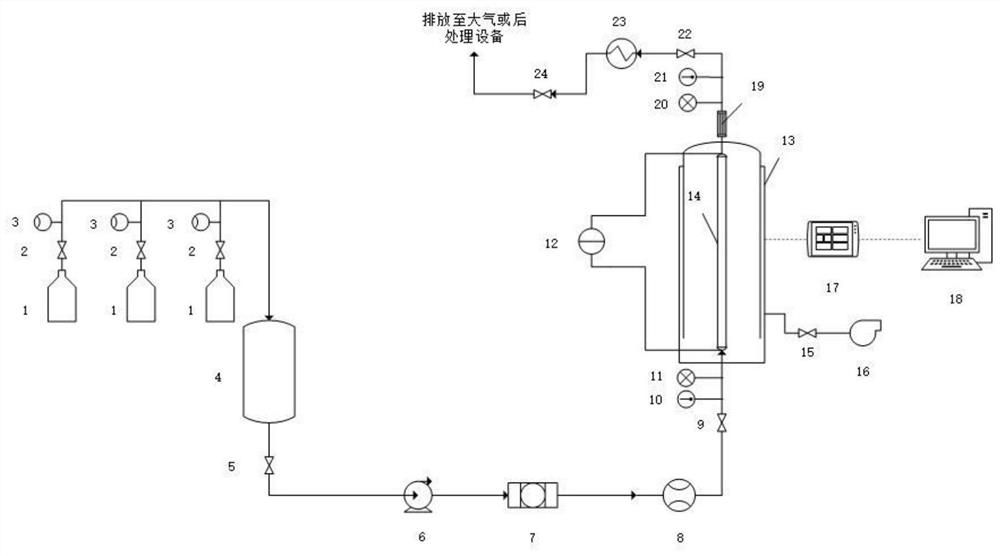

[0019] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] combined with figure 1 , the experimental system includes a liquid storage tank 1, according to the required mixed working fluid components and ratio, with the help of gate valve 2 and flow meter 3, the mixed working fluid is introduced into the working fluid mixing tank 4 for uniform mixing. The gear pump 6 is installed behind the working fluid mixing tank to drive the fluid in the experimental pipeline, and the filter 7 is installed in the experimental pipeline to filter the impurities that may exist in the pipeline. 8 Test the mass flow rate of the mixed working fluid in the pipeline. A temperature sensor 10 needs to be installed before the test section to measure the inlet fluid temperature before the test section and a pressure sensor 11 to measure the inlet pressure of the test section, and the test section 14 is heated by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com